Amazon Unveils Vulcan: A Warehouse Robot with Human-Like Touch Sensing

15 Sources

15 Sources

[1]

Amazon Has Made a Robot With a Sense of Touch

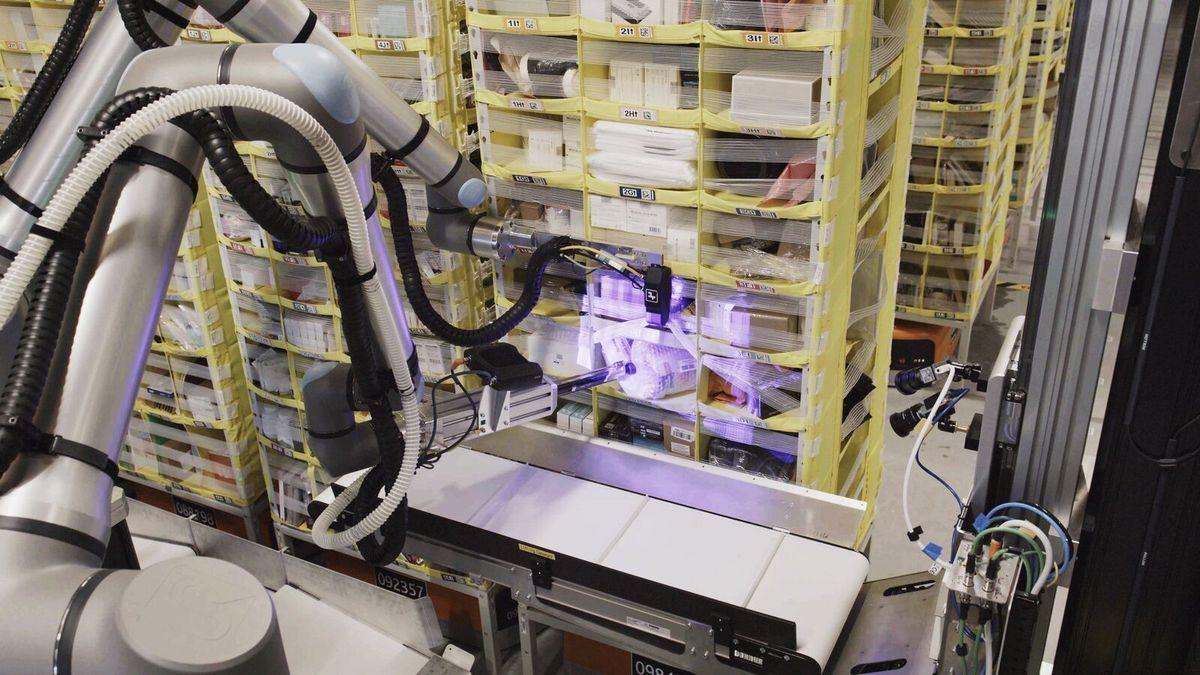

The robot, called Vulcan, is a meaningful step towards making robots less sausage-fingered compared to human beings. Honing robots' tactile abilities further may allow them to take on more fulfillment and manufacturing work in the years ahead. Aaron Parness, Amazon's director of robotics AI who led the development of Vulcan, explains that touch sensing helps the robot push items around on a shelf and identify what it's after. "When you're trying to stow [or pick] items in one of these pods, you can't really do that task without making contact with the other items," he says. The Vulcan system consists of a conventional robotic arm with a custom spatula-like appendage for poking into a shelf, and a sucker for grabbing items to pull them out. Vulcan has sensors on several of its joints that allow the robot to detect the edge and contours of items. Parness says that machine learning is key to making sense of the sensor signals and also forms part of the algorithmic loop that controls how a robot takes actions. "The special sauce we have is the software interpretation of the force torque, and how we wrap those into our control loop and into our motion plans," he says. Amazon revealed Vulcan at a fulfillment center in Hamburg, Germany today. The company says the robot is already working at this facility and another in Spokane, Washington. The new robots will work on the same line as human pickers, and will aim to spare them from back-aching work by grasping more items from shelves that are high up or low down. Items that the robot decides it cannot find will be reassigned to human workers. "Amazon stores many different products in bins, so rummaging is necessary to pull out a specific object to fill an order," says Ken Goldberg, a roboticist at the University of California, Berkeley. "Until now this has been very difficult, so I'm curious to see the new system." Goldberg says that research on robotic touch sensing has advanced in recent years, with numerous groups working on joint and surface sensing. But he added that robots have some way to go before they can match the tactile abilities of flesh-and-blood workers. "The human sense of touch is extremely sensitive and complex, with a huge dynamic range," Goldberg says. "Robots are progressing rapidly but I'd be surprised to see human-equivalent [skin] sensors in the next five-to-ten years." Even so, Vulcan should help automate more of the work currently done by humans inside Amazon's vast empire of fulfillment centers. The company has ramped up automation in recent years with AI-infused robots capable of grabbing and transporting packages and packed boxes. Stowing and retrieving items from shelves is one of the more challenging jobs for robots to do, and it is heavily dependent on human labor. Parness says he does not foresee robots taking on all of the work done inside Amazon's fulfillment centers. "We don't really believe in 100 percent automation, or lights out fulfillment," he says. "We can get to 75 percent and have robots working alongside our employees, and the sum would be greater [than either working alone]."

[2]

Amazon Unveils AI-Using Warehouse Robot With Human-Like Sense of Touch

Freelance writer Amanda C. Kooser covers gadgets and tech news with a twist for CNET. When not wallowing in weird gear and iPad apps for cats, she can be found tinkering with her 1956 DeSoto. Amazon's new Vulcan fulfillment center robot doesn't look humanoid, but it has some very human characteristics, like the ability to "feel" the items it's handling. Amazon introduced Vulcan at its Delivering the Future event in Germany on May 7. "Built on key advances in robotics, engineering, and physical AI, Vulcan is our first robot with a sense of touch," the company said in a statement. The event is a showcase for Amazon's technology innovations. Vulcan can stow or pick items from the fabric-covered pods Amazon uses for inventory storage. It has a human-like finesse when handling objects. Force feedback sensors help the robot avoid damaging the merchandise. A suction cup and camera system comes into play when Vulcan is pulling items out of bins. "While the suction cup grabs it, the camera watches to make sure it took the right thing and only the right thing, avoiding what our engineers call the risk of 'co-extracting non-target items,'" Amazon said. Vulcan is in place at fulfillment centers in Spokane, Wash. and Hamburg, Germany. It's primarily tasked with reaching items stored low that require a human to bend down, or items stored up high that require an employee to use a stepladder. The rise of robots in traditionally human-powered workplaces can be a sensitive subject. Amazon makes it clear it sees Vulcan as an assistant to its employees rather than a replacement for them. Vulcan can handle 75% of the types of items stocked at the fulfillment centers. It's designed to know which ones it can move and which ones it needs to ask for human help for -- like a robot-human tag team. The robot uses a physical AI system that includes "algorithms for identifying which items Vulcan can or can't handle, finding space within bins, identifying tubes of toothpaste and boxes of paper clips and much more." The AI was trained on everything from socks to electronics and continues to learn as the robot works. Humans and robots can effectively coexist in distribution centers, said logistics and operations researchers Rene de Koster of Erasmus University in the Netherlands and Debjit Roy of the Indian Institute of Management Ahmedabad. "Right now, at least, distribution center automation with people in the mix is often a more efficient, flexible and cost-effective bet than a completely automated center," the team said last year in a summary of their research for the Harvard Business Review. Robots have long been part of Amazon's operations with over 750,000 robots deployed in its fulfillment centers, the company said. Vulcan will roll out to more centers in Europe and the US over the next couple of years, increasing the chances of your future Amazon shipments having Vulcan's unseen "fingerprints" on them.

[3]

Amazon's new robot has a sense of touch, but it's not here to replace humans

Amazon has just unveiled its newest warehouse robot called Vulcan, which has a "sense of touch". Designed to gently stow items using pressure-sensitive gripping and artificial intelligence (AI), Vulcan is now being tested in two Amazon facilities, in Spokane, Washington state, US, and Hamburg, Germany. The robot is part of Amazon's long-term investment in warehouse automation. The inevitable question that always comes up is: will robots like this replace human workers? In short: not yet, and probably not completely. In fact, Vulcan is a good example of how robotics are being designed to work with people, not against them. Vulcan is designed to assist warehouse workers in stowing - the process of placing items into storage bins (called pods) before they're picked, packed and shipped. Human pickers often work at different height levels when they're stowing, with repetitive bending, reaching or climbing of steps. Amazon has divided the workspace into zones: the "kneel and lunge" zone (low height), the "power" zone (mid height), and the "ladder" zone (high height). Vulcan is designed to operate in the lowest and highest zones - the most physically demanding areas for humans - to reduce the risk of injury and improve efficiency. The "sense of touch" comes from Vulcan's force-sensitive gripper. This adjusts how firmly it should hold each item. Using AI, Vulcan can predict the right amount of force to use, squeezing gently for soft, squishy items, and more firmly for flat or rigid ones. It also uses a clever flat prong to make space inside the bins, packing things more efficiently, almost like playing a game of Tetris. Right now, Vulcan can match the speed of a human worker and operate for around 20 hours a day. The movements are fast, hence it still works behind a protective safety fence. However, it's not flawless - it can only handle objects up to about 8lbs (3.6kg) and struggles with round items. Get your news from actual experts, straight to your inbox. Sign up to our daily newsletter to receive all The Conversation UK's latest coverage of news and research, from politics and business to the arts and sciences. The human factor So, does this mean fewer jobs for humans? New technologies often raise concerns about job losses - and in some cases, with good reason. Some roles will inevitably disappear as robots become more commonplace, especially those that are dull, dirty, or dangerous. But that's only part of the picture. From what I've seen in my own research and experience with robotics, automation doesn't usually eliminate jobs entirely - it changes them. Amazon insists that Vulcan is being introduced not to replace staff, but to reduce the physical strain of repetitive tasks and support faster, safer warehouse operations. Importantly, Amazon also runs a Mechatronics and Robotics Apprenticeship Program - a free course for workers to upskill and move into more technical roles, often with a pay increase of up to 40%. The company also runs other upskilling programmes. Though it's also worth repeating here that Amazon has been the subject of criticism and complaints from employees about its intensive working conditions (Amazon says its employees' safety and health is its top priority and that some inaccurate information has gone around), these kinds of upskilling initiatives are key to the future of work in environments that use robots. As machines take over the repetitive tasks, humans will move into roles involving assembly, commissioning, maintenance, quick repair, and eventually, system reconfiguration. Get your news from actual experts, straight to your inbox. Sign up to our daily newsletter to receive all The Conversation UK's latest coverage of news and research, from politics and business to the arts and sciences. Join The Conversation for free today. In theory, a fully automated, 24/7 "lights-out" warehouse sounds like a dream for business - no breaks, no injuries, no wages. But in practice, completely removing humans from the shop floor is incredibly risky. Robots and automation systems, especially those that are used in an environment as complex as Amazon's logistics and warehouse management chain, can break down. If even one component in the workflow fails - a sensor, a motor, or a software module - and there are no humans around to spot it or fix it quickly, the entire operation could grind to a halt. In high-volume environments like Amazon warehouses, even an hour of downtime could cost a fortune. Keeping humans in the loop provides the flexibility and quick thinking that complex systems still depend on. It's a safety net no algorithm can yet replace. It's also a way to adapt to changes quickly, something that rigid automation often can't do. Vulcan isn't Amazon's first robot, and it won't be the last. Earlier systems like Sparrow could handle about 60% of the company's inventory. With Vulcan, that number jumps to 75%. That's certainly progress, but it also shows the limits of automation. There's still a long way to go before a robot can match the flexibility, judgement and care of a human worker. The future of robotics in warehouses won't be about replacing people, it will be about working alongside them, easing physical strain, increasing efficiency, and creating new types of jobs. We're already seeing shifts in the industry. Modular robots are built using a core set of hardware "modules" that can be combined and recombined to form a customised machine. These are making it easier to tailor automation. At the same time, vendor lock-in - where companies rely on proprietary hardware and software from a single supplier - is becoming less common. Instead, firms like Amazon are increasingly developing their own bespoke components to better suit their operational needs. A shift towards in-house, self-deployable robotics would mean that companies will need more technically skilled workers who can assemble, modify, and maintain these systems. For now, Vulcan is a glimpse of what's coming: smarter robots, safer work and hopefully, a future where technology supports people, not the other way around.

[4]

Amazon's newest fulfillment robot has a sense of touch

The company announced Vulcan at its Delivering the Future event. Amazon has deployed over 750,000 robots to its fulfillment centers over the last decade or so, but now there's a new, shall we say, more sensitive addition. The company has announced Vulcan, its first robot with a sense of touch. It's one in a series of new robots introduced today at Amazon's Delivering the Future event in Germany. Vulcan uses force feedback sensors to monitor how much it's pushing or holding on to an object and, ideally, not damage it. "In the past, when industrial robots have unexpected contact, they either emergency stop or smash through that contact. They often don't even know they have hit something because they cannot sense it." Aaron Parness, Amazon director, applied science, stated in the release. "Vulcan represents a fundamental leap forward in robotics. It's not just seeing the world, it's feeling it, enabling capabilities that were impossible for Amazon robots until now." Of course, there's an AI component, with Amazon training Vulcan's AI on physical data around touch and force. Vulcan also uses algorithms to determine what it can handle, identify different products and find space in the fulfillment center. The machine has "tackled thousands" of objects and tasks, like moving electronics and picking up socks. The system can also learn from its mistakes, with Amazon stating the robot will become more capable as time goes on. Amazon, which has faced continual reports of endangering worker safety, also claims it's introducing Vulcan for efficiency and worker safety. The robot should focus on inventory in the top rows of storage pods, about eight feet in the air, and just above floor level. Theoretically, this means less time employees need to spend on ladders or crouching down, and more time working with product at their level. Amazon says the robot is already in use in Spokane, Washington and Hamburg, Germany.

[5]

Amazon unveils warehouse robot with sense of touch, raising more concerns about job losses

Serving tech enthusiasts for over 25 years. TechSpot means tech analysis and advice you can trust. What just happened? Amazon has unveiled a revolutionary new robot that has a sense of touch, which will allow it to handle around three quarters of all items in the company's warehouses at a speed comparable to humans. It's a worrying claim for the hundreds of thousands of people in Amazon's facilities, but the company is once again claiming the new robot will work alongside humans, not replace them. The Vulcan robot represents a "fundamental leap forward in robotics," according to Amazon. It uses a sensor, powered by AI, to essentially feel items it picks up, determining the exact amount of pressure and torque required to safely handle each object. Vulcan's robotic sense of touch means it is able to pick and stow approximately 75% of the 1 million items at the Amazon fulfillment center in Spokane, Washington, where it has been deployed. The robot arms Amazon currently use in its facilities rely on cameras and suction to manipulate objects, meaning they struggle with many items, especially delicate ones. Amazon has long said that its robots are there to perform mundane, time-consuming, and dangerous tasks. In Vulcan's case, it will be picking and stowing inventory on the top rows of inventory pods. These rows are about 8 feet high, meaning employees need a ladder to reach them. Vulcan can also handle items stored just above the floor, which Amazon says allows employees to "work where they're most comfortable." It could also reduce the risk of injuries, something Amazon's facilities are notorious for. Vulcan is able to manipulate items weighing up to 8 pounds. It operates behind a fence to reduce the risk of accidents involving human workers. Amazon has increased the number of robots in its warehouses from 350,000 in 2021 to more than 750,000 today. Reports claim they could save the tech giant up to $10 billion a year by 2030, so it's easy to understand why employees are worried, especially as Vulcan is able to work 20 hours per day and at the same speed as a human. Aaron Parness, who leads the Amazon Robotics team that developed Vulcan, told CNBC that instead of replacing people in warehouses, Vulcan will create new, higher-skilled jobs that involve maintaining, operating, installing, and building the robots. Amazon says it has spent $1.2 billion upskilling human workers since 2019. Parness added that Amazon would never have a fully automated warehouse in the future. "I don't believe in 100% automation," he said. "If we had to get Vulcan to do 100% of the stows and picks, it would never happen. You would wait your entire life. Amazon understands this." It's not just Amazon embracing robots that can do human jobs without salaries, breaks, or vacations. GXO Logistics, a global contract logistics company that provides supply chain services to businesses around the world, has been testing the same autonomous machines in its facilities.

[6]

Amazon unveils its first warehouse robot with a sense of touch

The tech giant this morning unveiled what it describes as its first warehouse robot with a sense of touch. The robot, dubbed Vulcan, uses force sensors and AI to handle and organize inventory with human-like precision, the company says. Vulcan is already running in Amazon fulfillment centers in Spokane, Wash., and Hamburg, Germany, with future deployments planned across Europe and the U.S. Amazon is facing growing competition from other retailers and tech companies that are also using robots to speed up warehouse work. At the same time, critics warn that too much automation could put jobs at risk or create new safety problems. The company says the goal is not just to boost efficiency but also to make its fulfillment centers safer, helping its human workers, not replacing them. Amazon has steadily ramped up its deployment of warehouse robots in recent years Vulcan is the latest example. The company says the new robot is designed to reduce repetitive strain by taking on physically demanding tasks that often require workers to stretch, bend, or reach in awkward ways. The robot mimics human touch to handle items in warehouse bins, using a specialized tool with force feedback sensors to sense contact and pressure. Amazon describes the mechanism on the end of the arm as "a ruler stuck onto a hair straightener." One part pushes items around to make space, while paddle-like arms gently grip and insert new items using tiny conveyor belts. For picking items, another of the robot's arms uses a camera and a suction cup to identify, target, and extract items without grabbing anything extra.

[7]

Amazon's new warehouse robot has 'a sense of touch'

Summary Amazon unveiled Vulcan, a warehouse robot with 'a sense of touch,' at an event in Germany. Vulcan adds/removes items from pods using a camera-equipped arm with a suction cup. Amazon says Vulcan is meant to supplement its human workforce. Amazon unveiled a new warehouse robot at an event today in Dortmund, Germany (via The Verge). The company calls Vulcan, which uses a combination of sensors and onboard AI to gauge how to interact with Amazon's vast inventory of products, "our first robot with a sense of touch." Amazon already uses a number of robots in its warehouses for various tasks. The company says that because it can tell the difference between different items and "understand when and how it makes contact with an object," Vulcan has the potential to make the company's fulfillment process even more efficient -- that is, faster and less costly. Vulcan is able to both add individual items to and remove items from the one-foot-square pods used to store inventory in Amazon warehouses. These pods typically hold 10 items each. Amazon says its other robots, which don't exhibit as much dexterity as Vulcan, are ill-suited to this task. Source: Amazon To add items to bins, Vulcan uses a setup "that resembles a ruler stuck onto a hair straightener." Using the "ruler," Vulcan can push around items inside Amazon's pods, while paddles with built-in conveyor belts hold and place the item being added. When picking items, Vulcan uses an arm with a camera and a suction cup. The robot's software evaluates the camera feed to find items and determine how best to pick them up, then the section cup grabs the item. Amazon says the robot has the ability to pick up and move about 75 percent of the items stored in its warehouses, about as quickly as human workers can. It's also able to determine when it can't manipulate a given item and call for human help. Related I saw the future of robot vacuums in NYC, and Roborock has it armed with wild new features Robot vacuums are evolving beyond brushes and mops Posts 'Making our workers' jobs easier' Vulcan joins the more than 750,000 robots Amazon has deployed in its fulfillment centers since 2013. The company says that this has "created hundreds of new categories of jobs at Amazon, from robotic floor monitors to on-site reliability maintenance engineers," though automation results in fewer positions overall. Amazon is the second-largest private employer in the US, with the majority of its workers laboring in fulfillment centers. The company says Vulcan is meant to operate alongside human workers -- Amazon's director of applied science Aaron Parness says "the combination is better than either on their own." Vulcan robots are set to be deployed throughout the US and Europe "over the next couple of years."

[8]

Amazon makes 'fundamental leap forward in robotics' with device having sense of touch

Vulcan device 'capable of grabbing three-quarters of items in warehouses' fuels fears of mass job losses Amazon said it has made a "fundamental leap forward in robotics" after developing a robot with a sense of touch that will be capable of grabbing about three-quarters of the items in its vast warehouses. Vulcan - which launches at the US firm's "Delivering the Future" event in Dortmund, Germany, on Wednesday and is to be deployed around the world in the next few years - is designed to help humans sort items for storage and then prepare them for delivery as the latest in a suite of robots which have an ever-growing role in the online retailer's extensive operation. Aaron Parness, Amazon's director of robotics, described Vulcan as a "fundamental leap forward in robotics. It's not just seeing the world, it's feeling it, enabling capabilities that were impossible for Amazon robots until now." The robots will be able to identify objects by touch using AI to work out what they can and can't handle and figuring out how best to pick them up. They will work alongside humans who now stash and retrieve items from shelving units which are manoeuvred to them at picking stations by wheeled robots - of which Amazon now has more than 750,000 in operation. Vulcan will be able to stow items on the upper and lower levels of the shelving units - known as pods - so that humans no longer need to use ladders or bend so often during their work. Robots now operating in Amazon's warehouse are able to shift items around or pick items using suction cups and computer vision. The development is likely to raise fears of job losses as retailers reduce human involvement in distribution centres, which employ thousands of people. Many retailers have said that they are increasing investment in automation as labour costs rise around the world. Amazon has faced industrial action in the UK and elsewhere over low pay in its warehouses. Economists at Goldman Sachs speculated in 2023 that 300m jobs worldwide could be automated out of existence by 2030 as a result of the development of generative AI, with many more roles radically transformed. In the UK, between 60,000 and 275,000 jobs could be displaced every year over a couple of decades at the peak of the disruption, estimates from the Tony Blair Institute suggested last year. However, Tye Brady, the chief technologist of robotics at Amazon, said robots could not completely replace humans in the group's warehouses and were there to "amplify the human potential" and to improve safety in the workplace. The self-confessed "Star Wars geek" said the robots he helps design could be likened to R2D2 as "an amazing collaborative robot". "People will always be part of the equation," he said, while machines will take on "the menial, the mundane and the repetitive" tasks. "There's no such thing as completely automated. It just doesn't exist, because you always need people to understand the value of the operation, just using common sense, like, is that really doing the job?" He said having people involved could help protect against potential hacks of the system - as retailers increase efforts to protect themselves after the shutdown of Marks & Spencer's online orders following a cyber-attack. "All hacking could possibly be detected by a machine, but they're usually detected by people, so having people be part of the equation is a good thing," Brady said. He added that humans are also best for spotting more prosaic problems, such as broken or spilt items in a delivery that could cause problems for the system. Brady says that AI is helping to develop robots that can navigate complex spaces autonomously and learn to move safely alongside people and other objects. He said the latest generation of robots were able to "ask for help" so that they could learn new ways of doing things. "It's really exciting to bring both the mind and the body together," he said. "It's finally here, and it's just beginning." For example, Amazon plans to install technology, which uses machine-learning and automation to create bespoke packaging that will cut waste. More than 70 of the machines will be installed in Germany, UK, France, Italy and Spain by the end of this year, with dozens more to follow by 2027. The announcement comes as Amazon this week launched its low-cost Amazon Haul site in the UK, which promises thousands of products for £20 or less, as the group takes on cut-price operators Shein and Temu.

[9]

Amazon's new robot has a sense of touch, but it's not here to replace humans

Amazon has just unveiled its newest warehouse robot called Vulcan, which has a "sense of touch." Designed to gently stow items using pressure-sensitive gripping and artificial intelligence (AI), Vulcan is now being tested in two Amazon facilities, in Spokane, Washington state, US, and Hamburg, Germany. The robot is part of Amazon's long-term investment in warehouse automation. The inevitable question that always comes up is: will robots like this replace human workers? In short: not yet, and probably not completely. In fact, Vulcan is a good example of how robotics are being designed to work with people, not against them. Vulcan is designed to assist warehouse workers in stowing -- the process of placing items into storage bins (called pods) before they're picked, packed and shipped. Human pickers often work at different height levels when they're stowing, with repetitive bending, reaching or climbing of steps. Amazon has divided the workspace into zones: the "kneel and lunge" zone (low height), the "power" zone (mid height), and the "ladder" zone (high height). Vulcan is designed to operate in the lowest and highest zones -- the most physically demanding areas for humans -- to reduce the risk of injury and improve efficiency. The "sense of touch" comes from Vulcan's force-sensitive gripper. This adjusts how firmly it should hold each item. Using AI, Vulcan can predict the right amount of force to use, squeezing gently for soft, squishy items, and more firmly for flat or rigid ones. It also uses a clever flat prong to make space inside the bins, packing things more efficiently, almost like playing a game of Tetris. Right now, Vulcan can match the speed of a human worker and operate for around 20 hours a day. The movements are fast, hence it still works behind a protective safety fence. However, it's not flawless -- it can only handle objects up to about 8lbs (3.6kg) and struggles with round items. The human factor So, does this mean fewer jobs for humans? New technologies often raise concerns about job losses -- and in some cases, with good reason. Some roles will inevitably disappear as robots become more commonplace, especially those that are dull, dirty, or dangerous. But that's only part of the picture. From what I've seen in my own research and experience with robotics, automation doesn't usually eliminate jobs entirely -- it changes them. Amazon insists that Vulcan is being introduced not to replace staff, but to reduce the physical strain of repetitive tasks and support faster, safer warehouse operations. Importantly, Amazon also runs a Mechatronics and Robotics Apprenticeship Program -- a free course for workers to upskill and move into more technical roles, often with a pay increase of up to 40%. The company also runs other upskilling programs. Though it's also worth repeating here that Amazon has been the subject of criticism and complaints from employees about its intensive working conditions (Amazon says its employees' safety and health is its top priority and that some inaccurate information has gone around), these kinds of upskilling initiatives are key to the future of work in environments that use robots. As machines take over the repetitive tasks, humans will move into roles involving assembly, commissioning, maintenance, quick repair, and eventually, system reconfiguration. In theory, a fully automated, 24/7 "lights-out" warehouse sounds like a dream for business -- no breaks, no injuries, no wages. But in practice, completely removing humans from the shop floor is incredibly risky. Robots and automation systems, especially those that are used in an environment as complex as Amazon's logistics and warehouse management chain, can break down. If even one component in the workflow fails -- a sensor, a motor, or a software module -- and there are no humans around to spot it or fix it quickly, the entire operation could grind to a halt. In high-volume environments like Amazon warehouses, even an hour of downtime could cost a fortune. Keeping humans in the loop provides the flexibility and quick thinking that complex systems still depend on. It's a safety net no algorithm can yet replace. It's also a way to adapt to changes quickly, something that rigid automation often can't do. Vulcan isn't Amazon's first robot, and it won't be the last. Earlier systems like Sparrow could handle about 60% of the company's inventory. With Vulcan, that number jumps to 75%. That's certainly progress, but it also shows the limits of automation. There's still a long way to go before a robot can match the flexibility, judgment and care of a human worker. The future of robotics in warehouses won't be about replacing people, it will be about working alongside them, easing physical strain, increasing efficiency, and creating new types of jobs. We're already seeing shifts in the industry. Modular robots are built using a core set of hardware "modules" that can be combined and recombined to form a customized machine. These are making it easier to tailor automation. At the same time, vendor lock-in -- where companies rely on proprietary hardware and software from a single supplier -- is becoming less common. Instead, firms like Amazon are increasingly developing their own bespoke components to better suit their operational needs. A shift toward in-house, self-deployable robotics would mean that companies will need more technically skilled workers who can assemble, modify, and maintain these systems. For now, Vulcan is a glimpse of what's coming: smarter robots, safer work and hopefully, a future where technology supports people, not the other way around.

[10]

Amazon introduces Vulcan: an AI-powered warehouse robot with a sense of touch - SiliconANGLE

Amazon introduces Vulcan: an AI-powered warehouse robot with a sense of touch Online retailer titan Amazon.com Inc. today unveiled a new warehouse robot during its Delivering the Future event in Dortmund, Germany, named Vulcan, the company said represents a "fundamental leap forward in robotics." Vulcan brings the first robot that has a sense of touch to Amazon's array of warehouse robots to assist workers in the company's fulfillment centers. "In the past, when industrial robots have unexpected contact, they either emergency stop or smash through that contact," said Aaron Parness, Amazon's director of robotics. "They often don't even know they have hit something because they cannot sense it." This problem is known as robots being "numb and dumb," as most robots are connected to a visual intelligence system capable of seeing but not feeling. For humans, the sensation of touch is a profound marker of how to interact with an object, especially if part of it is out of sight or is not entirely rigid, such as a box that suddenly crumples when compressed - a good indicator that you should stop gripping it so tightly and maybe grab it somewhere else. Amazon said Vulcan was built on key advancements from Physical AI, a combination of artificial intelligence with real-world sensor data to allow autonomous machines to perceive, understand and interact with the physical world. Most machines only work with visual and location data to get their jobs done, but the addition of force feedback sensory information allows for manipulating objects in a more human way. Vulcan isn't the first robot Amazon produced that can grab and sort parcels and items. It also has other bird-named systems, Sparrow, Cardinal and Robin, which use vision AI and suction cups. Roving robots of Greek-named origins, Proteus, Titan and Hercules, move products around warehouses and fulfillment centers. According to Amazon, the new robot can pick and stow around 75% of all items that flow through its warehouses at speeds comparable to front-line workers. Its underlying robot brain can also identify when it can't move a specific item and ask a human worker to step in to assist. "Vulcan works alongside our employees, and the combination is better than either on their own," said Parness. To that end, the robots will work with warehouse employees and not simply replace them, the company said. Its capabilities will be used to help them become safer in moving orders along more efficiently. It will be used to take over the more physically taxing parts of the fulfillment process. "Working alongside Vulcan, we can pick and stow with greater ease," said Kari Freitas Hardy, a front-line employee at GEG1, a fulfillment center in Washington, in a quote provided by Amazon. "It's great to see how many of my co-workers have gained new job skills and taken on more technical roles." The company said Vulcan can learn from its own failures and understands how different objects behave when touched. It builds an understanding of the real world through training on examples of real-world physical objects that pass through its sensors, just like kids do. As a result, it will become smarter as time passes. Amazon has deployed the new robots at its fulfillment centers in Spokane, Washington, in full operation. A test version is currently in operation in Hamburg, Germany. It can pick items from inventory. The company said it plans to add Vulcan to more warehouses in the United States and Germany by 2026.

[11]

Amazon Unveils Vulcan, Its First Robot With a Sense of Touch

Amazon introduced Vulcan, its first robot with a sense of touch, at its Delivering the Future event in Dortmund in Germany. The robot is being deployed in fulfilment centres to improve worker safety, operational efficiency, and the speed at which customer orders are processed. Vulcan, already in use at sites in Washington, USA, and Hamburg, Germany, can handle roughly 75% of item types stored at Amazon facilities. Developed through advancements in robotics, engineering, and physical AI, Vulcan helps employees by picking and stowing products, especially in hard-to-reach areas. This development comes after Amazon announced earlier in February that it formed a brand-new frontier AI and robotics (FAR) team based in San Francisco and Seattle. "Vulcan works alongside our employees, and the combination is better than either on their own," Aaron Parness, director of applied science at Amazon Robotics, said. "It's not just seeing the world, it's feeling it, enabling capabilities that were impossible for Amazon robots until now." Unlike previous robots that lacked sensory feedback, Vulcan uses force feedback sensors and a specialised arm tool to identify contact and adjust grip strength. This enables it to handle products more delicately and efficiently within confined storage bins. It also reduces the need for employees to use step ladders or work in less ergonomic positions. Kari Freitas Hardy, a front-line worker at Amazon's fulfilment centre in Spokane, noted the benefits of working alongside Vulcan. "It's great to see how many of my co-workers have gained new job skills and taken on more technical roles, like I did," she said. Vulcan is part of a broader automation strategy that has already seen over 7.5 lakh robots deployed across Amazon's network. "Our vision is to scale this technology across our network, enhancing operational efficiency, improving workplace safety, and supporting our employees by reducing physically demanding tasks," Parness added.

[12]

Amazon's Vulcan Robots Can Consciously Apply Force While Picking Objects

The company is testing the robot in select fulfilment centres Amazon introduced a new warehouse-focused robot last week that can carefully manipulate a wide range of objects. Dubbed Vulcan, the new class of robots feature force feedback sensors that allow it to understand the amount of force it is applying while picking an object or pushing a cart. These robots will be used in the tech giant's fulfilment centres globally and are designed to assist the human workers. Amazon said that these robots have created hundreds of new categories of human jobs at the warehouses. In a newsroom post, the Seattle-based tech giant introduced Vulcan and highlighted its capabilities. The new robots solve a critical problem in automating Amazon's fulfilment centres - robots are numb and dumb. "In the past, when industrial robots have unexpected contact, they either emergency stop or smash through that contact. They often don't even know they have hit something because they cannot sense it," said Aaron Parness, Director, Applied Science, Amazon. The company highlighted that Vulcan, which is built using advances in robotics, engineering, and physical AI, comes with dedicated force feedback sensors. Its arm is also fitted with a camera and a suction cup. The entire assembly uses both sensor-based object detection as well as computer vision to understand the amount of force it can apply. Vulcan robot's ruler-shaped arm with camera and suction cup Amazon's inventory storage in its fulfilment centres follows a specific arrangement to make shipping and stowing easy. Inventory is stored in fabric-covered pods that are divided into compartments. Each compartment holds up to 10 different items. Most robots struggle to pick objects from this mix of objects, but Vulcan is said to be able to navigate through the crowded space to carefully pick the required item. Vulcan can pick and stow around 75 percent of all the items the company stores at its fulfilment centres, with speeds comparable to its front-line employees, Amazon said. Currently, the Vulcan robots are being tested at their fulfilment centres in Spokane, Washington and Hamburg, Germany. Amazon highlighted that currently, it has deployed more than 7,50,000 robots into its fulfilment centres. The company was also quick to note that this large number of robots has also created new categories of jobs, such as robotics floor monitors and on-site reliability maintenance engineers. The tech giant is also offering training programmes to its human workers to move into robotics and find a place in an industry that is quickly taking the automation route.

[13]

Vulcan: How Amazon's robot locates and retrieves products using vision and touch

Amazon has introduced a new warehouse robot, Vulcan, designed to locate and retrieve products by using both vision and touch -- mimicking the way humans navigate cluttered environments. CEO Andy Jassy described it as "the first robot that combines sight and touch", allowing it to "feel its way through cluttered spaces the way humans do". "Vulcan is helping make work safer by handling ergonomically challenging tasks, while creating opportunities for our teammates to grow their skills in robotics maintenance," Jassy shared in a post on X. Vulcan features a robotic arm equipped with a camera and a suction cup. The system identifies the desired item using the camera, determines the best spot to grip it, and then carefully removes it from a shelf -- while ensuring no other products are mistakenly taken. This helps avoid what Amazon calls the risk of "co-extracting non-target items". Amazon said in a blog post that "with the ability to pick and stow approximately 75% of all various types of items we store at our fulfilment centres, and at speeds comparable to that our front-line employees, Vulcan represents a step change in how automation and AI can assist our employees in their everyday tasks." The robot is also equipped to recognise when it cannot handle a particular item and can call on a human worker for assistance. Creation of new jobs These robots now contribute to fulfilling about 75% of customer orders and have led to the creation of hundreds of new job roles, according to Amazon. These include positions such as robotic floor monitors and on-site reliability maintenance engineers. The company also claimed that it promotes training initiatives such as its 'Career Choice' programme, aimed at helping employees transition into robotics and other high-tech careers. Aaron Parness, Amazon's director of applied science, emphasised the importance of human-machine collaboration: "I don't believe in 100% automation. If we had to get Vulcan to do 100% of the stows and picks, it would never happen. You would wait your entire life. Amazon understands this." "Vulcan works alongside our employees, and the combination is better than either on their own," Parness added. The long-term aim is for Vulcan to take over all stowing tasks in the highest shelving rows -- areas that are challenging for human workers to reach -- thus reducing the risk of injury and improving overall workplace safety.

[14]

Amazon Unveils Revolutionary Robot 'Vulcan' With Sense Of Touch To Handle 75% Of The Warehouse Items: 'People Will Always Be Part Of The Equation' - Apple (NASDAQ:AAPL), Amazon.com (NASDAQ:AMZN)

Amazon AMZN has revealed a revolutionary robot, Vulcan, which boasts a sense of touch, enabling it to manage approximately 75% of items in Amazon's warehouses. What Happened: As per Amazon's announcement on Wednesday, Vulcan is set to be introduced at the company's "Delivering the Future" event in Dortmund, Germany. The groundbreaking robot is set to be globally deployed in the coming years, playing a pivotal role in the online retail behemoth's operations. According to Aaron Parness, Amazon's director of robotics, Vulcan represents a "fundamental leap forward in robotics." The robot will use AI to recognize objects through touch, assessing which ones it can handle and determining the most effective way to pick them up. Vulcan will work in conjunction with human employees, stowing items on the upper and lower levels of shelving units. This will reduce the need for human workers to frequently use ladders or bend during their work. Jeff Bezos's Amazon also plans to implement technology that uses machine learning and automation to create custom packaging, reducing waste. This technology will be installed in several European countries by the end of this year, with more installations planned by 2027. SEE ALSO: Tesla's Elon Musk Says Manually-Driven Cars Will Be 'Unusual' In The Future, Shares Updates On SpaceX, Neuralink Why It Matters: The unveiling of Vulcan comes amidst a growing trend of AI and robotics integration in various industries. Earlier this year, tech giants Apple Inc. AAPL and Meta Platforms Inc. META were reported to be in a race to develop AI-powered humanoid robots. Similarly, NVIDIA Corporation NVDA introduced new AI and robotics tools at the GTC event, indicating a future powered by advanced technology. Get StartedStart Futures Trading Fast -- with a $200 Bonus Join Plus500 today and get up to $200 to start trading real futures. Practice with free paper trading, then jump into live markets with lightning-fast execution, low commissions, and full regulatory protection. Get Started However, the rise of AI and robotics has also raised concerns about job security. in 2023, economists at Goldman Sachs projected that by 2030, generative AI could automate up to 300 million jobs globally, with many additional roles undergoing significant transformation, reported The Guardian. Meanwhile, Sen. Bernie Sanders has warned American workers about significant changes in the job market due to AI and robotics. Despite concerns about job losses due to increased automation, Tye Brady, the chief technologist of robotics at Amazon, told The Guardian that robots are there to "amplify the human potential" and enhance safety, not to entirely replace human workers. "People will always be part of the equation," asserted Brady. Amazon holds a Growth rating of 94.95% and a quality rating of 74.33%, according to Benzinga's Proprietary Edge Rankings. For an in-depth report on more stocks and insights into growth opportunities, sign up for Benzinga Edge. Shares of Amazon declined nearly 16% on a year-to-date basis. READ MORE: Dogecoin Teases 'Diamond Bottom' Reversal: Is A Breakout Imminent? - Benzinga Image via Shutterstock Disclaimer: This content was partially produced with the help of AI tools and was reviewed and published by Benzinga editors. AAPLApple Inc$200.801.15%Stock Score Locked: Want to See it? Benzinga Rankings give you vital metrics on any stock - anytime. Reveal Full ScoreEdge RankingsMomentum54.35Growth46.03Quality82.33Value8.28Price TrendShortMediumLongOverviewAMZNAmazon.com Inc$187.211.19%METAMeta Platforms Inc$592.320.85%NVDANVIDIA Corp$114.070.47%Market News and Data brought to you by Benzinga APIs

[15]

Amazon Introduces First Robot With Sense of Touch | PYMNTS.com

The average robot is "numb and dumb," particularly those operating in commercial settings, Aaron Parness, Amazon director of applied science, said in the post. "In the past, when industrial robots have unexpected contact, they either emergency stop or smash through that contact," he said. "They often don't even know they have hit something because they cannot sense it." Vulcan is built using advances in robotics, engineering and physical artificial intelligence to do its job, per the post. While it's not the first Amazon robot that can pick things up, its sense of touch -- that is, its ability to grasp when and how it makes contact with an object -- offers new ways for Amazon to bolster its operation-related jobs and facilities, the post said. "Vulcan represents a fundamental leap forward in robotics," Parness said in the post. "It's not just seeing the world, it's feeling it, enabling capabilities that were impossible for Amazon robots until now." Amazon's fulfillment centers feature compartments designed to hold up to 10 items. Fitting an item into one of these spaces can be tough for robots that lack human-like dexterity. Vulcan has "a similar kind of finesse," according to the post. "Vulcan can easily manipulate objects within those compartments to make room for whatever it's stowing because it knows when it makes contact and how much force it's applying and can stop short of doing any damage," the post said. "Vulcan does this using an 'end of arm tooling' that resembles a ruler stuck onto a hair straightener, plus force feedback sensors that tell it how hard it's pushing or how firmly it's holding something, so it can stay below the point at which it risks doing damage." The announcement followed reports from February that Amazon aims to glean savings from its robotics efforts as it increases spending on AI. Also in February, PYMNTS spoke with Jenny Shern, general manager at robot builder NexCOBOT, about the challenges of introducing humanoid robots to households. "[I]mplementing humanoid robots into household settings is a more complex advancement because, unlike factories, household environments are highly dynamic, and tasks will vary significantly from one home to another," Shern said.

Share

Share

Copy Link

Amazon introduces Vulcan, an AI-powered warehouse robot with a sense of touch, designed to work alongside human employees in fulfillment centers. The robot can handle 75% of inventory items, raising questions about automation and job security.

Amazon Introduces Vulcan: A Touch-Sensitive Warehouse Robot

Amazon has unveiled its latest innovation in warehouse automation: Vulcan, a robot with a human-like sense of touch. Designed to work alongside human employees in fulfillment centers, Vulcan represents a significant advancement in robotics technology and warehouse operations

1

.Technological Advancements

Vulcan's key feature is its ability to "feel" objects it handles, thanks to force feedback sensors and AI-powered algorithms. This tactile sensing allows the robot to adjust its grip and pressure when manipulating various items, from delicate products to heavier objects weighing up to 8 pounds

2

.The robot's design includes:

- A conventional robotic arm with a spatula-like appendage for shelf manipulation

- A suction cup for grabbing items

- Sensors on several joints to detect edges and contours of objects

- AI algorithms for interpreting sensor data and controlling actions

1

Operational Capabilities

Vulcan can handle approximately 75% of the items in Amazon's inventory, a significant increase from previous robots that could manage about 60%

3

. It operates at speeds comparable to human workers and can function for up to 20 hours a day5

.The robot is designed to work in specific zones within the warehouse:

- The "kneel and lunge" zone (low height)

- The "ladder" zone (high height)

These areas are typically the most physically demanding for human workers

3

.

Implementation and Future Plans

Vulcan is currently operational in two Amazon fulfillment centers:

- Spokane, Washington, USA

- Hamburg, Germany

2

Amazon plans to roll out Vulcan to more centers in Europe and the US over the next couple of years

2

.Related Stories

Impact on Workforce and Job Market

While the introduction of Vulcan raises concerns about potential job losses, Amazon maintains that the robot is designed to work alongside human employees, not replace them

4

. The company argues that Vulcan will:- Reduce physical strain on workers

- Improve efficiency and safety in warehouses

- Create new, higher-skilled jobs in robot maintenance and operation

5

To support this transition, Amazon offers upskilling programs, including a Mechatronics and Robotics Apprenticeship Program, which can lead to pay increases of up to 40%

3

.Industry Implications and Future Outlook

The development of Vulcan reflects broader trends in warehouse automation and robotics:

- Increased use of modular robots for customized automation

- A shift away from vendor lock-in towards bespoke components

- The continued importance of human workers for flexibility and problem-solving in complex warehouse environments

3

As Amazon's robot workforce grows from 350,000 in 2021 to over 750,000 today, the company projects potential savings of up to $10 billion annually by 2030 through automation

5

. However, Amazon maintains that fully automated warehouses are not the goal, emphasizing the continued importance of human workers in their operations5

.References

Summarized by

Navi

[3]

Related Stories

Amazon's Vulcan: The Warehouse Robot with a 'Sense of Touch' Reshaping Automation

22 May 2025•Technology

Amazon's Warehouse Robots: Revolutionizing Efficiency, but Challenges Remain

20 Nov 2024•Technology

Amazon's Robotics Revolution: Transforming Fulfillment Centers with AI and Automation

12 Oct 2024•Technology

Recent Highlights

1

ByteDance's Seedance 2.0 AI video generator triggers copyright infringement battle with Hollywood

Policy and Regulation

2

Demis Hassabis predicts AGI in 5-8 years, sees new golden era transforming medicine and science

Technology

3

Nvidia and Meta forge massive chip deal as computing power demands reshape AI infrastructure

Technology