Breakthrough in 4-Inch Heterostructure Fabrication Paves Way for Advanced AI Semiconductors

2 Sources

2 Sources

[1]

Fabrication of 4-Inch Wafer-Scale Heterostructure | Newswise

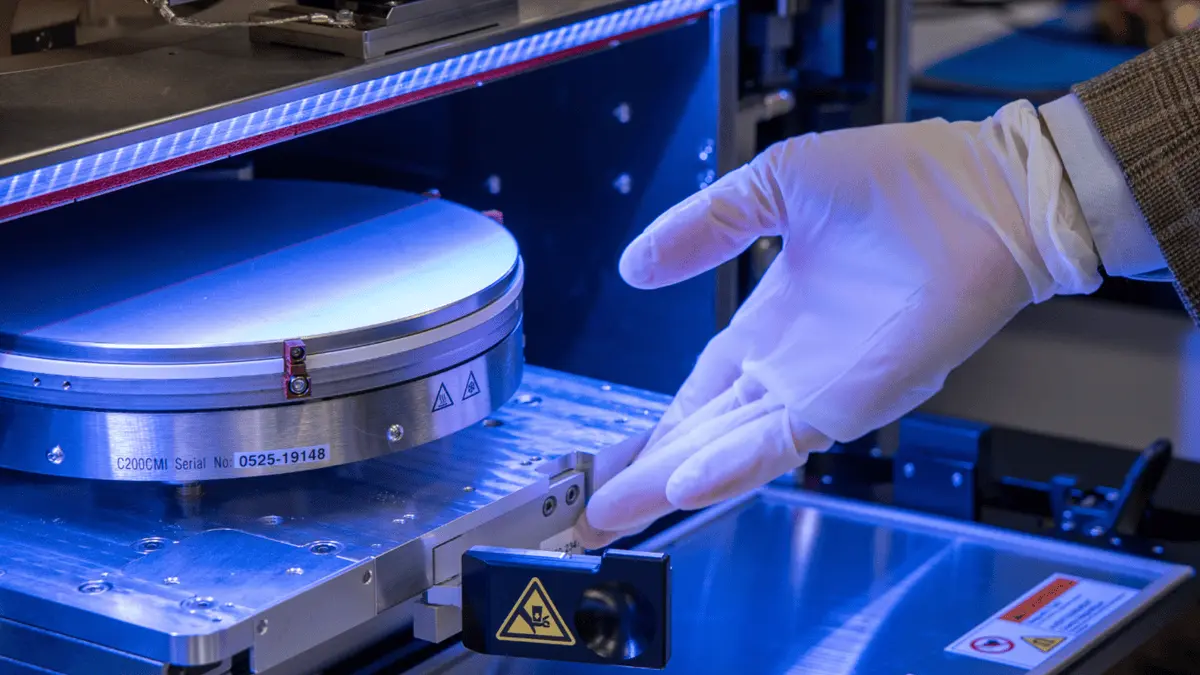

Newswise -- As artificial intelligence (AI) technology advances, the demand for higher-performing semiconductors is rapidly growing. The development of new materials and innovative structures to achieve high-performance semiconductors has become crucial. For the first time globally, a 4-inch heterostructure fabrication technology using plasma-enhanced chemical vapor deposition (PECVD) has been developed. This breakthrough enables the production of low-power, high-performance semiconductors, surpassing the capabilities of traditional silicon-based technology. The research team led by Senior Researcher Hyeong-U Kim of the Semiconductor Manufacturing Research Center of the Korea Institute of Machinery and Materials (President Seog-Hyeon Ryu, hereinafter referred to as KIMM), an institute under the jurisdiction of the Ministry of Science and ICT, collaboration with Professor Taesung Kim's team from the Department of Mechanical Engineering at Sungkyunkwan University (President Yoo Ji-Beom), has achieved the world's first successful fabrication of a 4-inch heterostructures semiconductor with using plasma technology. This technology is expected to be applicable to AI semiconductors by utilizing next-generation semiconductor materials like TMDc.* Using PECVD equipment, the research team succeeded in producing two types of 4-inch wafer-scale heterostructures. The first type, a heterostructure of WS₂ and graphene, was fabricated by depositing a 1-nanometer (nm) tungsten (W) metal layer onto a graphene-transferred wafer, followed by H₂S plasma sulfurization. Additionally, the team achieved a breakthrough with a metal-semiconductor heterostructure by combining two distinct forms of molybdenum disulfide (MoS₂) as thin film. The metallic 1T phase, with an orthorhombic structure, is metastable compared to the more stable hexagonal 2H phase, making large-area wafer production challenging. This new technology allowed the team to produce a 4-inch wafer in the 1T phase and successfully implement the 1T-2H heterostructure. Traditional method for heterostructure, such as stacking, were only allowed to small sizes of a few μm and had reproducibility issues. The team overcame these limitations by using PECVD to fabricate a 4-inch wafer-scale heterostructure. This breakthrough allows for the development of a 3D integrated structure, which significantly reduce power loss and heat dissipation, leading to enhance performance and energy efficiency -- key factors for low-power, high-performance AI semiconductors. KIMM's Senior Researcher Hyeong-U Kim stated, "This newly developed technology not only fulfills wafer-size and reproducibility requirements but also allows experimental validation previously restricted to academic research. Using PECVD, a widely employed tool in the semiconductor industry, this technology offers high potential for mass production, likely contributing to advancements in AI semiconductor performance and commercialization." KIMM has secured original technology for the two forms of 4-inch heterostructure wafer fabrication through patent registrations in both the United States and South Korea. Additionally, the research is featured in prominent journals, Advanced Materials** and Energy & Environmental Materials***. This research was supported by KIMM's core project on plasma equipment-based foundational technology development for semiconductor and display industry processes, KIMM's Creative Challenge Research Program, and the Ministry of Trade, Industry, and Energy's Human Resources Development Project. ### The Korea Institute of Machinery and Materials (KIMM) is a non-profit government-funded research institute under the Ministry of Science and ICT. Since its foundation in 1976, KIMM is contributing to economic growth of the nation by performing R&D on key technologies in machinery and materials, conducting reliability test evaluation, and commercializing the developed products and technologies.

[2]

Advance in 4-inch heterostructure fabrication enhances AI semiconductors

As artificial intelligence (AI) technology advances, the demand for higher-performing semiconductors is rapidly growing. The development of new materials and innovative structures to achieve high-performance semiconductors has become crucial. For the first time globally, a 4-inch heterostructure fabrication technology using plasma-enhanced chemical vapor deposition (PECVD) has been developed. This breakthrough enables the production of low-power, high-performance semiconductors, surpassing the capabilities of traditional silicon-based technology. A research team led by Senior Researcher Hyeong-U Kim of the Semiconductor Manufacturing Research Center of the Korea Institute of Machinery and Materials (KIMM), in collaboration with Professor Taesung Kim's team from the Department of Mechanical Engineering at Sungkyunkwan University, has achieved the world's first successful fabrication of a 4-inch heterostructures semiconductor with using plasma technology. The research is featured in Advanced Materials and Energy & Environmental Materials. This technology is expected to be applicable to AI semiconductors by utilizing next-generation semiconductor materials like TMDc. TMDc (transition metal dichalcogenides) is a material candidate for next-generation semiconductors with atomic-level, 2D structures offering silicon-like performance, low power operation, and fast switching speeds. It is particularly suitable for neuromorphic systems and used in machine learning, deep learning, and cognitive computing. (e.g., molybdenum disulfide, MoS, tungsten disulfide, WS, and molybdenum selenide, MoSe. Using PECVD equipment, the research team succeeded in producing two types of 4-inch wafer-scale heterostructures. The first type, a heterostructure of WS and graphene, was fabricated by depositing a 1-nanometer (nm) tungsten (W) metal layer onto a graphene-transferred wafer, followed by HS plasma sulfurization. Additionally, the team achieved a breakthrough with a metal-semiconductor heterostructure by combining two distinct forms of molybdenum disulfide (MoS) as a thin film. The metallic 1T phase, with an orthorhombic structure, is metastable compared to the more stable hexagonal 2H phase, making large-area wafer production challenging. This new technology allowed the team to produce a 4-inch wafer in the 1T phase and successfully implement the 1T-2H heterostructure. Traditional methods for heterostructure, such as stacking, were only allowed to small sizes of a few μm and had reproducibility issues. The team overcame these limitations by using PECVD to fabricate a 4-inch wafer-scale heterostructure. This breakthrough allows for the development of a 3D integrated structure, which significantly reduces power loss and heat dissipation, leading to enhanced performance and energy efficiency -- key factors for low-power, high-performance AI semiconductors. KIMM's Senior Researcher Hyeong-U Kim stated, "This newly developed technology not only fulfills wafer-size and reproducibility requirements but also allows experimental validation previously restricted to academic research. "Using PECVD, a widely employed tool in the semiconductor industry, this technology offers high potential for mass production, likely contributing to advancements in AI semiconductor performance and commercialization." KIMM has secured original technology for the two forms of 4-inch heterostructure wafer fabrication through patent registrations in both the United States and South Korea.

Share

Share

Copy Link

Korean researchers have developed a novel 4-inch heterostructure fabrication technology using plasma-enhanced chemical vapor deposition (PECVD), potentially revolutionizing AI semiconductor performance and production.

Breakthrough in Heterostructure Fabrication

Researchers from the Korea Institute of Machinery and Materials (KIMM) and Sungkyunkwan University have achieved a significant breakthrough in semiconductor technology. For the first time globally, they have successfully developed a 4-inch heterostructure fabrication technology using plasma-enhanced chemical vapor deposition (PECVD)

1

2

. This innovation is poised to revolutionize the production of low-power, high-performance semiconductors, surpassing the capabilities of traditional silicon-based technology.Novel Fabrication Techniques

The research team, led by Senior Researcher Hyeong-U Kim, employed PECVD equipment to produce two types of 4-inch wafer-scale heterostructures:

-

A heterostructure of tungsten disulfide (WS₂) and graphene: This was created by depositing a 1-nanometer tungsten metal layer onto a graphene-transferred wafer, followed by H₂S plasma sulfurization

1

. -

A metal-semiconductor heterostructure: This combines two distinct forms of molybdenum disulfide (MoS₂) as a thin film. The team successfully produced a 4-inch wafer in the metastable 1T phase and implemented the 1T-2H heterostructure

1

2

.

Advantages Over Traditional Methods

Traditional heterostructure fabrication methods, such as stacking, were limited to small sizes of a few micrometers and faced reproducibility issues. The new PECVD technique overcomes these limitations, enabling the fabrication of 4-inch wafer-scale heterostructures

1

2

. This breakthrough allows for the development of 3D integrated structures, which significantly reduce power loss and heat dissipation, leading to enhanced performance and energy efficiency – crucial factors for AI semiconductors1

.Related Stories

Implications for AI Semiconductor Industry

The newly developed technology is expected to have far-reaching implications for the AI semiconductor industry:

-

Improved Performance: The heterostructures enable the production of low-power, high-performance semiconductors, essential for advancing AI technology

1

2

. -

Mass Production Potential: Utilizing PECVD, a widely employed tool in the semiconductor industry, this technology offers high potential for mass production

1

. -

Application of Next-Generation Materials: The technology is applicable to AI semiconductors using next-generation materials like transition metal dichalcogenides (TMDCs), which offer silicon-like performance, low power operation, and fast switching speeds

2

.

Future Prospects and Commercialization

KIMM has secured patents for the two forms of 4-inch heterostructure wafer fabrication in both the United States and South Korea

1

2

. This positions them strongly for potential commercialization and further development of the technology.Senior Researcher Hyeong-U Kim emphasized that this technology not only meets wafer-size and reproducibility requirements but also allows for experimental validation previously restricted to academic research

1

2

. The breakthrough is expected to contribute significantly to advancements in AI semiconductor performance and commercialization.References

Summarized by

Navi

Related Stories

MIT Engineers Develop 'High-Rise' 3D Chip Technology for Advanced AI Hardware

19 Dec 2024•Technology

Breakthrough in AI Memory Technology: ECRAM's Hidden Mechanisms Unveiled

26 Apr 2025•Science and Research

Stanford team builds first commercial 3D chip at US foundry with 4x AI performance gains

14 Dec 2025•Science and Research

Recent Highlights

1

ByteDance's Seedance 2.0 AI video generator triggers copyright infringement battle with Hollywood

Policy and Regulation

2

Demis Hassabis predicts AGI in 5-8 years, sees new golden era transforming medicine and science

Technology

3

Nvidia and Meta forge massive chip deal as computing power demands reshape AI infrastructure

Technology