Digital Twins: Challenges and Building Blocks for Successful Implementation

2 Sources

2 Sources

[1]

Deploying digital twins: 7 challenges businesses can face and how to navigate them

Accuracy, complexity, costs, and skills availability may make it difficult to get the most out of digital twins, and even potentially misrepresent or miss actual changes in the status of systems or facilities. Digital twins have great promise -- the ability to simulate and improve the performance of systems, machines, facilities, and even entire ecosystems, at relatively low cost with software. "In today's world where it seems every day there's a new surprise, having that added insight to mimic your real world and make decisions based on the information and the data that's collected is highly valuable and important," Ara Surenian, vice president of product management for Plex by Rockwell Automation, told ZDNET. However, there are potential roadblocks to digital twin deployment and management. Accuracy, complexity, costs, and skills availability may make it difficult to get the most out of these applications, and even potentially misrepresent or miss actual changes in the status of systems or facilities. Also: How AI can help businesses design for positive externalities Issues that may be encountered with digital twins -- with measures suggested by industry leaders to help address those issues -- include the following: Building and maintaining digital twins can be a complex process. "A big mistake companies make is allowing their desire for perfect to get in the way of good enough," Christine Bush, director of the Robotic Center of Excellence for Schneider Electric, told ZDNET. "Like any digital transformation, it all starts with data. And in most every case, at the onset of the transformation, the data is rarely good enough. However, good enough is where the process needs to start because the transformation is a journey and needs to start in order to realize the downstream benefit." For this reason, industry leaders advocate moving cautiously when establishing digital twins. "Begin with pilot projects to showcase tangible ROI in controlled settings," Bush said. "This approach not only validates the technology but also helps secure budget approvals and organizational support." To properly scope digital twins, "focus on a specific location versus the entire end-to-end supply chain," Surenian agreed. "Find the location where the data is perceived to be the most readily available and accurate. From there, determine what questions and issues you wish to tackle with the digital twin. Ask yourself if it's easy to understand capacity, inventory, ability to meet demand, and other relevant questions." An organization adopting digital twins needs to be well-networked. "The biggest roadblock to digital systems is connectivity, at the network and human levels," Thierry Klein, president of Nokia Bell Labs Solutions Research, told ZDNET. "Digital twins are most effective when multiple digital twins are integrated, but this requires collaboration among stakeholders, a robust digital network, and systems that can be connected to the digital twin." Also: 5.5G touted as the network to bring improved enterprise connectivity Well-developed networks are "critical to ensure seamless data integration, real-time transmission and anywhere access supporting the scalability of digital twin implementations," Klein pointed out. Artificial intelligence (AI) can act as a booster to overcome such challenges, Klein added. An AI model integrated into digital twins can "analyze data collected from physical systems, renders the digital twin, recommends next-step actions and simulates multiple future scenarios and optimizations. It can also analyze data, enabling more sophisticated data analysis and network and process automation." The ability to represent physical environments in real time also presents challenges to digital twin environments. "With digital twins, you're generally relying on your model to run parallel with some real-life physical system so you can understand certain effects that might be impacting the system," Naveen Rao, vice president of AI for Databricks, told ZDNET. Also: If AI is the 'gas guzzler' of data, how do we get better mileage? "Take, for example, a digital twin of an aircraft jet engine. You could be using the digital twin to understand the efficiencies at different parts of the engine or to look for potential issues. If you don't have data being processed at a high enough velocity, you might give an alert too late when maintenance would be more expensive. Also, if your models aren't accurate, you could give poor recommendations and lose the trust of your maintenance team." The need for real-time connectivity also extends to end-users' abilities to view what's going on within a system or facility. Extended reality (XR) and virtual reality (VR) "offer innovative ways to visualize and simulate complex systems and processes, which is particularly valuable in industries like manufacturing, construction, and healthcare," said Bush of Schneider Electric. "However, their adoption faces practical challenges, especially in environments with high-speed machinery where safety concerns arise." At Schneider, the emphasis is on "implementing XR and VR primarily in controlled environments to mitigate risks such as physical collisions or distractions," Bush continued. "Despite the exciting possibilities XR and VR present for enhancing digital twins, ensuring operational safety remains paramount as we continue to innovate in this space." "The lack of open, interoperable data standards presents another significant roadblock. "Antiquated technology, legacy proprietary data formats, and analog processes create silos of 'dark data' -- or data that's inaccessible to teams across the asset lifecycle," Shelly Nooner, vice president of innovation and platform for Trimble, told ZDNET. "These data bottlenecks cause inefficiencies that can result in higher capital expenses and higher operational costs." Also: Three ways to create the right data culture in your business This is where industry groups need to step up and formulate common standards that enable greater digital connectivity. In the construction industry, for example, BuildingSmart is an organization dedicated to creating and adopting open, international standards and solutions for infrastructure and buildings. BuildingSmart, according to Nooner, "is addressing the civil infrastructure open data standard challenge. They have already proven their value within the building industry and continue to gain momentum with infrastructure construction." "Accurate data inputs from sensors and IoT devices are essential, but successful implementation also demands a well-organized approach and adequate resources," Robert Bunger, innovation product owner in the chief technology office for Schneider Electric, told ZDNET. The key is to "integrate diverse data sources and maintain synchronized models, which can be complex and resource intensive." Governance will play a role in managing such diversity. "Digital twin systems will need robust MLOps [machine learning operations] to ensure the latest and most accurate models can be constantly re-trained and deployed," said Rao. This includes "strong governance to ensure only the right people have access and audits can be done easily, and real-time observability so you know the moment your model, or source data, might be drifting or losing accuracy." As with many advanced technology projects that require engagement with systems across and outside the enterprise, digital twins require expertise in data integration, artificial intelligence, and software development. "Skill shortages and technology illiteracy are also roadblocks to digital twin deployment, "contributing to the lack of data accuracy and resistance to change," Ryan Hamze, principal consultant with ISG, told ZDNET. Also: Ready to upskill? Look to the edge (where it's not all about AI) Hamze advised "targeting investments for local workforce training and upskilling." Another option is "partnerships with third-party industry leaders will also help fill gaps." It's always important to keep the business front and center within any digital twin initiatives. "We are helping our clients overcome many of these roadblocks by engineering human-centric digital twins that function at the business process and business execution layers," Jason Noel, executive director of emerging technology for EY Consulting, told ZDNET. "Intelligent twins are designed to be used by business and operations roles, versus only technical engineers." A business-first strategy "will help propel the next generation of enterprise business applications where digital twins orchestrate insights, decision-making, and execution of both core and ancillary business functions," Noel added.

[2]

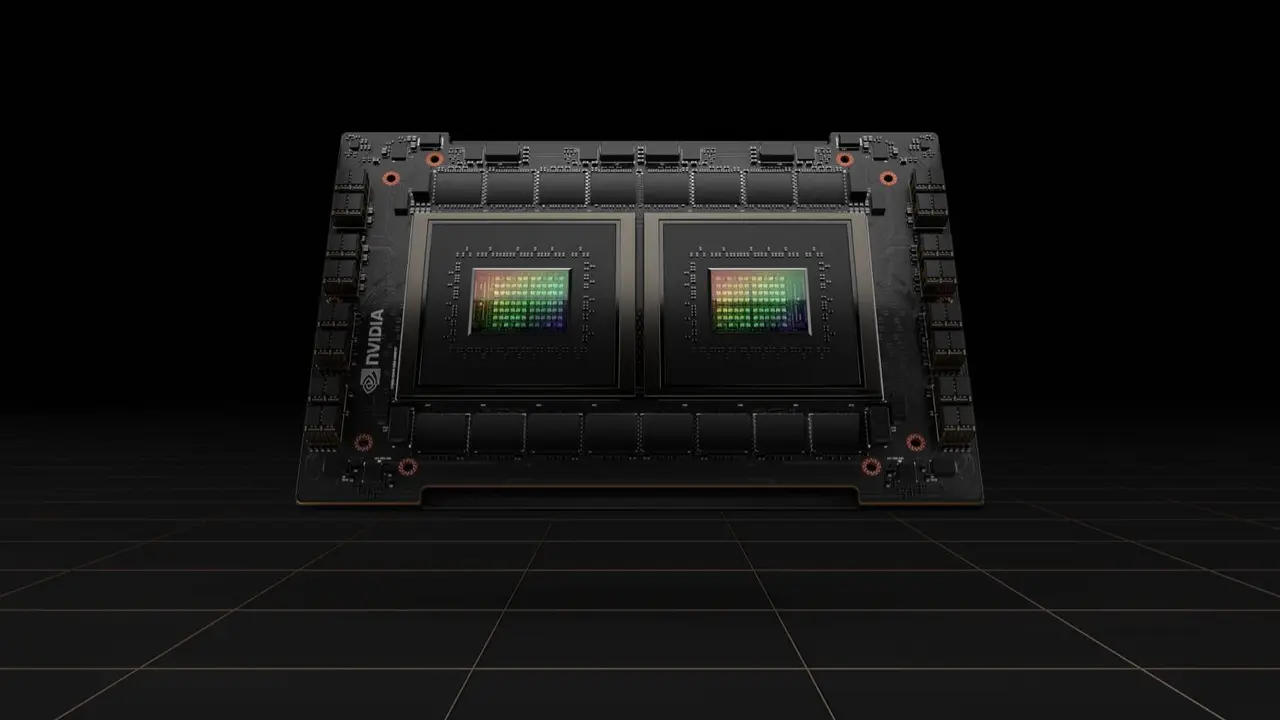

6 digital twin building blocks businesses need - and how AI fits in

Digital twins are receiving an AI boost, promising even greater predictive intelligence and ease of use, opening possibilities to a broad range of industries. Digital twins, emerging within organizations of all types, are ripe for a technological makeover. These digital representations of physical facilities or objects on which users can simulate outcomes and experiment with new ideas have been especially prominent within the manufacturing sector, and have even been referred to as the "industrial metaverse." Now, digital twins are receiving a boost from artificial intelligence (AI), promising even greater predictive intelligence, ease of use, and opening possibilities to a broad range of industries. In addition, emerging interfaces such as extended reality (XR), virtual reality (VR), and augmented reality (AR) augur even deeper exploration into the systems that power enterprises. Generative AI (GenAI), in particular, now offers text-based and conversational AI to digital twin efforts, helping users assemble and deploy these technologies within weeks or days, a 2024 McKinsey report states. "Many organizations are separately implementing digital twins and generative AI -- two technologies with distinct value propositions and tremendous promise -- to support a wide range of use cases," observe the McKinsey co-authors, led by Alex Cosmas and Guilherme Cruz. AI accelerates the process of designing and building digital twins. "Building a digital twin, especially for highly specialized applications -- such as multimachine production scheduling or vehicle routing -- can be time-consuming and resource-intensive," the McKinsey analysts note. "The effort often entails designing and developing new digital-twin models, a process that can take six months or longer and incur substantial labor, computing, and server costs." Also: Time for businesses to move past generative AI hype and find real value The inclusion of GenAI with digital twins enables the rapid creation of code and also opens up vast stores of information, Pascal Brosset, global lead for production and operations at Accenture Industry X, told ZDNET. "It allows the twin to tap into the vast repositories of unstructured data available in companies' intranets, and give people access to the resulting structured information in natural language." Conversely, digital twins of AI systems can also be constructed, enabling users to fine-tune their models. The integration of AI models is the latest boost to the power of digital twins. But digital twins require a multi-layer foundation that extends from actual physical objects, wired to deliver data, to data stores to end-user interfaces. The foundation of digital twin implementations incorporates the following basic components. Physical assets consist of the environments or components that will be digitally replicated. These could range from entire facilities to individual machine parts. The data layer is where data is sourced, stored, and transformed for delivery to the digital twin application. It's important that such a data foundation is built on "the most relevant and high-quality data possible," Naveen Rao, vice president of AI for Databricks, told ZDNET. "This data could take many forms, so it's important that your data platform supports many types of data -- structured, unstructured, real-time, and batch. Ideally, this data also lives in a highly performant format, so it can be efficiently used downstream to both train models and be used for analysis." Also: Beware of AI 'model collapse': How training on synthetic data pollutes the next generation This includes "a model that represents some physical system at its core," said Rao. "These models enable predictive analytics, help optimize systems, and influence important business decisions. To keep these models as accurate as possible, organizations need to track their model experimentation from raw data to deployment and through every stage of their model evolution." Importantly, before the selection of technologies for a digital twin, "organizations have to have the right philosophy in place for their entire suite of data," Simon Bennett, director of innovation and incubation at Aveva, told ZDNET. "What data do they store? How much of this is essential for running the business? Is the data consistently representing the real world? Who owns the data? Is intellectual property locked away in the data? Is it up to date? Is it managed and cared for? A well-funded and clear strategy for the management of data is the primer needed for starting the journey to a digital twin. Arguably, the selection of technologies is considerably easier to organize." - Simon Bennet Digital twins typically represent complex environments and therefore depend on data collected, preferably in real time, from all key points and processes. These can include essential IoT technologies such as "sensors, 5G, cobots, augmented reality, virtual reality, simulation and GenAI reporting analytics," Ryan Hamze, principal consultant with ISG, told ZDNET. IoT sensors "are the foundation of digital twins," agrees Logan Mallory, vice president of marketing at Motivosity. "These sensors collect real-time data from actual assets, providing the necessary information for precise digital reproductions. For example, in a manufacturing setting, IoT sensors on machinery monitor temperature, vibration, and their operational status, sending continuous data to the digital twin." One of the most compelling aspects of digital twin adoption is the use of visualization tools -- employing XR or VR -- that enable users to enter (virtually) the premises of digital realms to conduct simulations, do fact-finding, and even repair systems. "These technologies provide immersive visualizations that help stakeholders interact with digital twins in more intuitive and impactful ways," Jen Mowery, M.Ed., instructor of agile methodologies and project management at Harrisburg University of Science and Technology, told ZDNET. "In sectors like advanced manufacturing and health futures, XR and VR enable detailed simulations and training applications, while in mobility and advanced agriculture, they facilitate design, planning, and real-time decision-making." Also: 7 upgrades Apple Vision Pro needs to succeed in business However, XR and VR integration into the digital twin world is still in the earliest stages and "only used in very special cases," said Accenture Industry X's Brosset. "The requirement for quality and constantly updated 3D data is a high hurdle to more general adoption." In the past five years, "we've seen increased use of XR and VR, but their high cost contributes to lagging adoption," Hamze added. "However, they have proven to be much more cost-effective than traditional approaches in the long run in their main areas of use, which are predictive maintenance, training, and simulation within digital environments. We expect to see an uptick in XR, VR, and AR implementations, especially with GenAI being integrated into those solutions." Governance and lineage are also essential to assuring that digital twin efforts are delivering on their investments. "Organizations need a strong grasp on governing both the data and the AI models training on said data," Rao said. "A strong governance solution should be able to give fine-grained access across the entire model pipeline, yet be simple enough to manage so that it doesn't slow down development speed. There also needs to be a framework to correlate the outputs of the model against outputs of the real system." Also: AI risks are everywhere - and now MIT is adding them all to one database It's also important to involve domain experts in the entire life cycle of the digital twin, Manfred Kügel, data scientist and IoT industry advisor to SAS, told ZDNET. "These experts typically have lots of ideas how to build digital twins to increase efficiency. They know how to best implement digital twins for maximum gain. And once a digital twin is running, domain experts recognize when it needs to be retrained. Involving domain experts in building, implementing, and running a digital twin will also help ensure smoother adoption and better results." The technology building blocks for digital twins are now all available through the cloud. Cloud-based services "provide access to cutting-edge hardware like the latest GPUs, networking, and data storage," said Rao. At the same time, "some organizations might still require on-premises technology for specific use cases that demand higher security or have latency concerns," Mowery observed. "We advocate for a hybrid approach that combines the strengths of both cloud and on-premises solutions to meet diverse needs." Also: How your business can best exploit AI: Tell your board these 4 things In addition, "fast communications are essential," Tim Rawlins, senior adviser and director at NCC Group, told ZDNET. "The use of public and private 5G networks is increasingly common, while the move to edge computing and 6G networks should significantly increase data transfer speeds and reduce latency, thereby supporting more effective modeling." While manufacturing is seeing strong adoption of digital twin technology, its reach crosses industry boundaries. "Environments as diverse as town planning -- where digital twins combine architectural plans, building information management systems, pedestrian and vehicular traffic flows, air quality, energy use, weather patterns, city and emergency services and development visualization -- to help engage communities in what the city might become," said Rawlins. In advanced manufacturing, "digital twins enable the simulation and optimization of production processes, leading to increased efficiency and reduced downtime," Mowery said. "In the mobility sector, digital twins are revolutionizing vehicle design and maintenance through real-time monitoring and predictive analytics. Health futures are also benefiting from digital twins in personalized medicine and patient care, where virtual replicas of organs and systems enhance diagnostics and treatment planning. Additionally, advanced agriculture is leveraging digital twins to optimize crop management and improve sustainability." Also: Want to clone yourself? Make a personal AI avatar - here's how Digital twin technology has also proven to be a valuable tool within process manufacturing, such as oil and gas or chemical companies, Brosset said. "Their sophisticated plant control systems are de-facto digital twins, which can be easily extended with AI and machine learning optimization logics. Food and beverage companies, whose continuous processes lend themselves to similar optimizations, are catching up fast because they are under extreme pressure to reduce costs and become more flexible."

Share

Share

Copy Link

Digital twins are revolutionizing business operations, but their implementation comes with challenges. This article explores the hurdles companies face and the essential components needed for successful digital twin deployment.

Understanding Digital Twins

Digital twins, virtual replicas of physical assets or processes, are transforming how businesses operate and make decisions. These digital representations provide real-time insights and predictive capabilities, enabling companies to optimize performance, reduce costs, and innovate faster

1

.Challenges in Digital Twin Deployment

While the potential benefits are significant, businesses face several challenges when implementing digital twins:

-

Data Quality and Integration: Ensuring accurate, real-time data from various sources can be difficult

1

. -

Scalability: As digital twins grow more complex, maintaining performance at scale becomes challenging

1

. -

Security and Privacy: Protecting sensitive data and ensuring compliance with regulations is crucial

1

. -

Interoperability: Ensuring different systems and platforms can communicate effectively is essential

1

. -

Skill Gaps: Finding and retaining talent with the necessary expertise can be difficult

1

.

Essential Building Blocks for Digital Twins

To overcome these challenges and successfully implement digital twins, businesses need to focus on six key building blocks:

-

Data Collection and Integration: Gathering and combining data from various sources, including IoT devices and existing systems

2

. -

3D Modeling and Visualization: Creating accurate 3D representations of physical assets or processes

2

. -

Real-time Simulation: Enabling dynamic simulations that reflect real-world conditions and changes

2

. -

AI and Machine Learning: Leveraging advanced analytics for predictive insights and optimization

2

. -

Cloud Computing: Providing the necessary infrastructure for scalability and accessibility

2

. -

User Interface and Experience: Designing intuitive interfaces for effective interaction with digital twins

2

.

Related Stories

The Role of AI in Digital Twins

Artificial Intelligence plays a crucial role in enhancing the capabilities of digital twins. AI algorithms can process vast amounts of data, identify patterns, and make predictions, enabling more accurate simulations and proactive decision-making

2

.Overcoming Implementation Challenges

To navigate the challenges of digital twin deployment, businesses should:

- Invest in robust data management and integration strategies.

- Prioritize scalable architecture and cloud-based solutions.

- Implement strong security measures and ensure regulatory compliance.

- Foster collaboration between IT and OT teams to improve interoperability.

- Develop training programs to address skill gaps and nurture in-house expertise

1

.

References

Summarized by

Navi

Related Stories

Recent Highlights

1

ByteDance Faces Hollywood Backlash After Seedance 2.0 Creates Unauthorized Celebrity Deepfakes

Technology

2

Microsoft AI chief predicts artificial intelligence will automate most white-collar jobs in 18 months

Business and Economy

3

Google reports state-sponsored hackers exploit Gemini AI across all stages of cyberattacks

Technology