Hyundai labor union blocks humanoid robots over warnings of mass job losses in factories

5 Sources

5 Sources

[1]

Hyundai's humanoid robot plans trigger union warnings of mass job losses

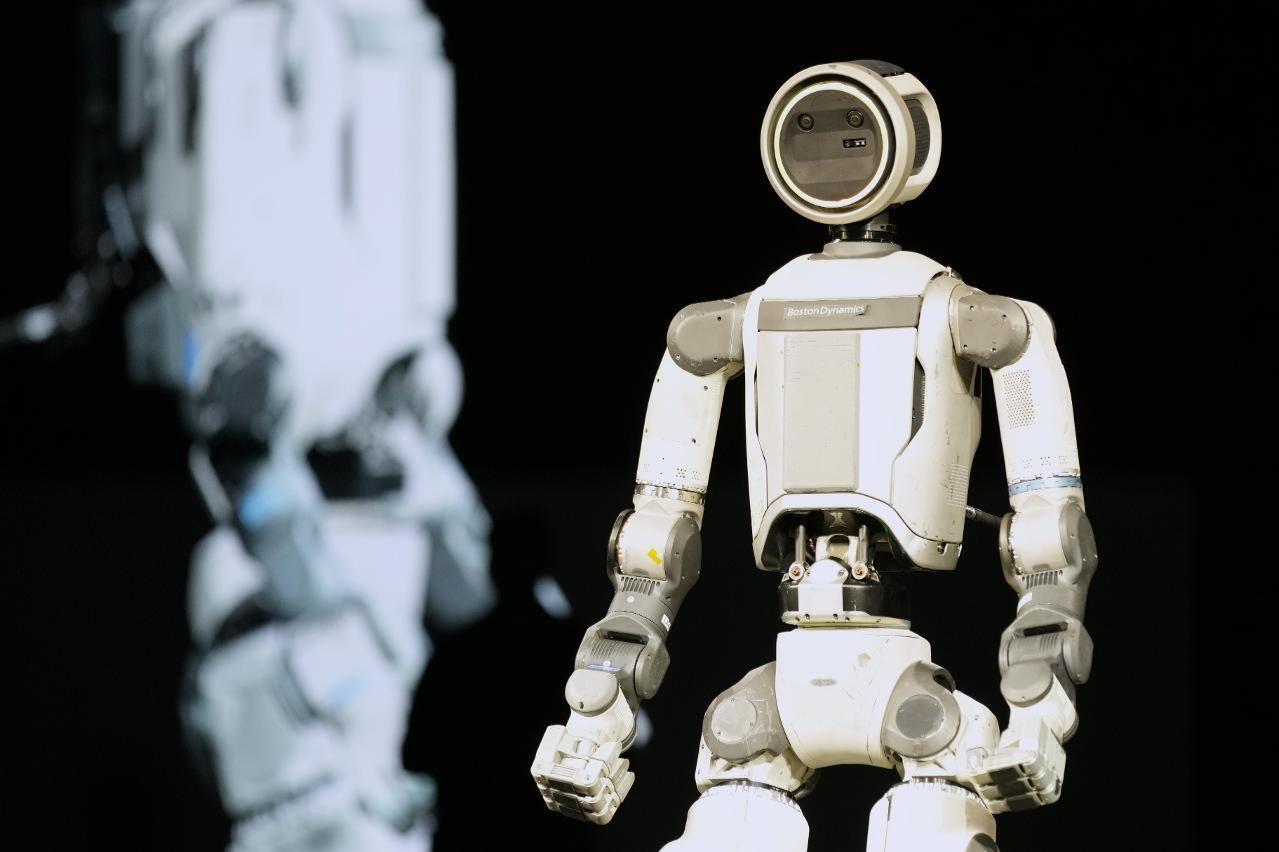

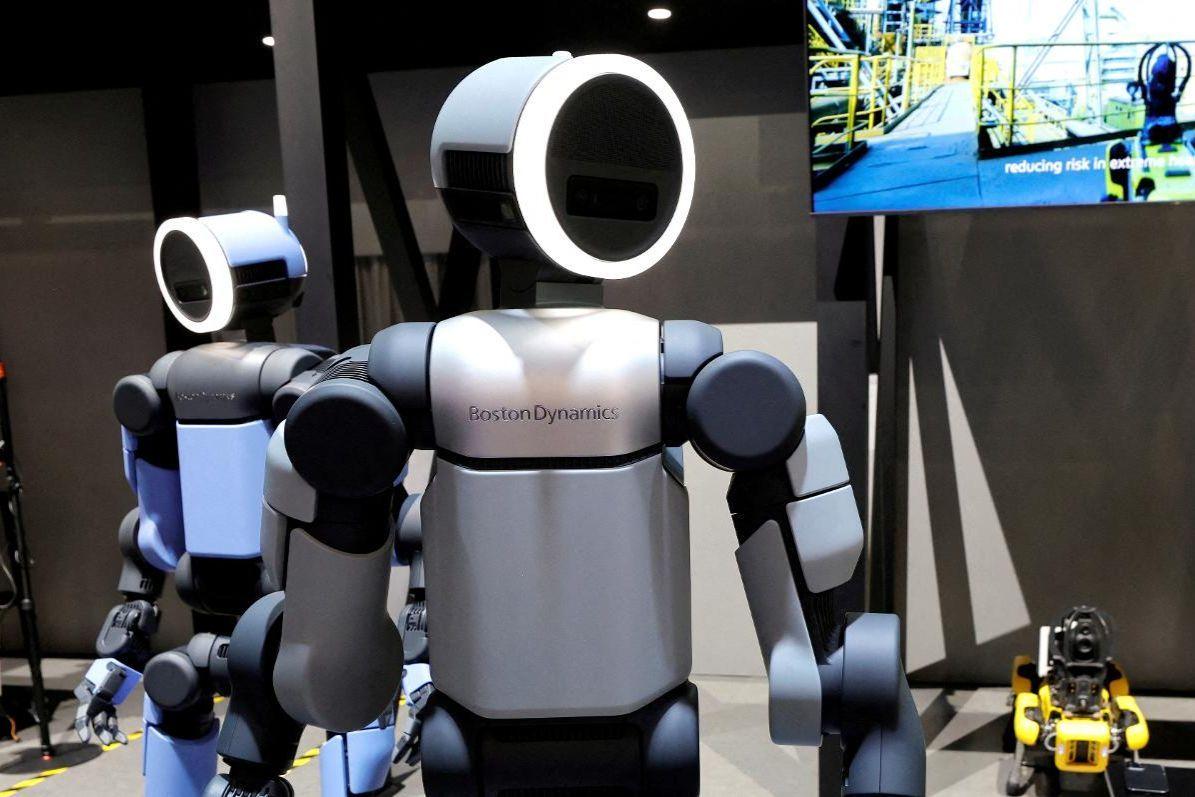

Serving tech enthusiasts for over 25 years. TechSpot means tech analysis and advice you can trust. A hot potato: The fear of generative AI taking office jobs has somewhat overshadowed the issue of robots replacing factory workers. But in Korea, Hyundai Motor's labor union has warned against the company's plans to use humanoid robots in its factories, saying it would bring a "huge employment shock." Hyundai Motor Group showed off Boston Dynamics' Atlas robot at CES earlier this month. The company said it plans to build a factory capable of producing 30,000 robots annually by 2028 and to begin deploying humanoid robots at its Georgia plant that same year, with plans to roll them out across all global production sites. As is usually the case after an organization announces it is embracing AI/robots, Hyundai's share price reached a record high following the news. However, the company's labor union is far from pleased. It has accused Hyundai of trying to boost its profits and reduce its workforce through the use of automation. "Under no circumstances will workers welcome the plan, as the robot deployment will bring a huge employment shock," the union said. "The union warns that not a single robot can be deployed at worksites without an agreement between the union and management." Regarding the threat to human jobs, Hyundai has toed the standard line about how Atlas will ease the physical burden on workers and carry out jobs that are potentially dangerous to humans. But the union says the move is simply about increasing long-term profits at the cost of human jobs. The annual maintenance costs of a robot like Atlas are estimated to reach $9,500, far less than a typical worker's wages. Moreover, Robots don't require sick days, vacation time, rest, or lunch and bathroom breaks. "This is a good excuse for capitalists who seek to maximize profits from a long-term viewpoint," the union said. The union also slammed Hyundai over its plans to expand production overseas, including the US. The company said its Georgia factory will reach annual production capacity of 500,000 vehicles by 2028 to meet rising demand in the US market. In October, there were reports that Amazon aims to replace 600,000 of its US warehouse workers with robots. The New York Times wrote that Amazon's robotics team hopes to automate 75% of all operations at the company, thereby eliminating 160,000 positions that would have otherwise been required by 2027. Amazon quickly responded to the report by promising, once again, that the robots would not replace workers. The claim may have held more weight had Amazon not used the announcement to also unveil two more factory robots designed to replace workers.

[2]

Hyundai labor union warns humanoids could trigger major job losses

The union further leveled allegations that the carmaker was seeking profits by reducing the workforce through the deployment of robots. "This is a good excuse for capitalists who seek to maximize profits from a long-term viewpoint," the union said. The typical maintenance cost of an Atlas humanoid robot is estimated at about $9,500 per year, much lower than the annual labor costs. Hyundai Motors hasn't released an official comment on this issue yet. Engineered for factories At CES 2026, Hyundai earmarked the Atlas humanoid robot as a central part of its Physical AI, saying human involvement will be retained even post-deployment. The brand plans to shift the robot from research and demos to real-world production-line use. According to reports, the humanoid robots will be phased in from 2028, starting with simple tasks like parts sequencing. By 2030, Hyundai aims to deploy robots for complex, heavy-duty operations across production lines. The Group confirmed it was moving beyond hardware-focused robotics toward AI-driven systems that pair Boston Dynamics' platforms with Hyundai's manufacturing scale and factory data to train, deploy, and refine collaborative robots.

[3]

'Yellow envelope law' meets age of robot workers - The Korea Times

An Atlas robot stands on stage during a Hyundai and Boston Dynamics press conference ahead of the CES tech show in Las Vegas, Jan. 5 (local time). AP-Yonhap Conflict over robots controlled by artificial intelligence (AI) is no longer a scenario in the distant future for Korea. It is unfolding in real time, as changes to the country's labor law give unions new leverage over how quickly and extensively companies can replace human workers with machines. Experts say the recently enacted pro-labor "yellow envelope law" set to take effect in March may slow the transition to robot labor. The law expands workers' rights in labor disputes and limits employers' ability to seek damages from unions over strike-related losses, giving unions more leverage. Paradoxically, it could also hasten automation, as companies rush to install robots before union power increases and their legal risks grow. Nowhere has that tension become more evident than at Hyundai Motor, which has become a test case for how far unions, employers and the government can go to shape the coming wave of "physical AI," with AI robotic systems carrying out hands-on work on factory floors. The company announced last week that it plans to mass-produce Atlas humanoid robots at a new U.S. plant by 2028, and gradually deploy them across its assembly lines. Hyundai Motor is pitching the project as the cornerstone of its physical AI future, in which AI-controlled industrial machines work alongside or in place of humans to handle risky or monotonous tasks. Some industry analysts estimate annual maintenance costs at roughly 14 million won ($9,700) for each Atlas robot, which can operate for nearly 24 hours a day, compared with human employees who cost the company about 130 million won per year each. Unionized workers at Hyundai Motor protested the move, saying in a statement "not a single robot" will be allowed onto the assembly floor without a labor-management agreement. This warning is being taken seriously. Under the new law, management decisions that significantly affect working conditions are recognized as matters for collective bargaining and action. Large-scale automation projects fall squarely into that category, according to labor experts. That means unions can more easily strike or take other collective action to resist or shape robot deployment strategies. "This is a turning point for Korea," Ahn Jong-ki, a professor at the Korea University Institute for Research on Labor and Employment, told The Korea Times. He believes that in structural terms, the direction is already set. "Large-scale substitution of human labor by robots and AI is unavoidable, and it is likely to proceed much faster than most people expect," he said. "The real question is not whether this will happen, but whether labor, capital and the state will use this moment to find a balance that lets us prosper together." The scholar said the carmaker's 2028 target may already represent a compromise -- a way to "test the waters" with unions and the public -- rather than the earliest date it could realistically roll out AI robots at scale. Recent advances showcased at events such as CES, he added, suggest the technology is close to deployment readiness. "The conditions for rapid change are already in place," he said. "Since Hyundai Motor raised the flag, companies in China and the U.S. will not sit still ... It will only be a matter of time before fully robotized production systems can be built." Tensions are already visible in the rhetoric around the company's Atlas plan, with the union expressing concerns about a major "employment shock." Employers, meanwhile, may be tempted to turn more toward robots. With automation options multiplying and labor rules tightening, some could pursue aggressive restructuring -- a risky move in a country already grappling with tensions over social and economic inequalities. If employers conclude that human labor has become too litigious because of the yellow envelope law, that pressure could harden their resolve to automate, experts say. But taking such an aggressive strategy would be a costly mistake, said Lee Jong-sun, another professor at the Institute for Research on Labor and Employment. "We already have tens of thousands of young people who can't find decent work," he said. "Manufacturing still provides some of the best stable jobs. If large companies ignore that and focus only on cost, they will face resistance and the country as a whole may end up paying a broader price." Both professors said opposing automation outright is neither realistic nor desirable. Robots and AI can take over the most dangerous and grueling tasks, while also improving national competitiveness while peer economies are rearming and reindustrializing. The real task for policymakers is to manage the transition smoothly, they added. "Korea has the chance to become a test bed not just for physical AI but for a new social model around it," Ahn said. "If labor, companies and the government can use tools like the yellow envelope law to create a shared strategy instead of a permanent war, Hyundai's Atlas could mark the beginning of a new kind of prosperity."

[4]

Hyundai's 'Atlas' robot sparks debate over human labor, jobs in Korea

Hyundai Motor Group's announcement of plans to deploy its new humanoid robot "Atlas" in manufacturing facilities has been met with fierce backlash from the company's labor union. Industry observers note that South Korea is No. 1 in the world in terms of robot adoption in factories, indicating significant potential for the more widespread utilization of robots -- and accompanying controversy. "We will not tolerate any orders that have not been agreed upon by both the labor union and management," the Hyundai Motor branch of the Korean Metal Workers' Union stated in its newsletter on Thursday, addressing the transfer of production volume to Hyundai Motor Group Metaplant America (HMGMA) in Georgia and the introduction of new robotic automation technology. "We will not allow any robots to enter production sites without our permission," the union stated, signaling a direct confrontation with the company, which is pursuing cost reduction and production efficiency. The labor union's strong distrust of automation is symbolized by Atlas, a humanoid robot model. Boston Dynamics, a US robotics company acquired by Hyundai Motor, unveiled Atlas at CES 2026 earlier this month. Hyundai Motor announced its plan to deploy Atlas at HMGMA starting in 2028 and its aim to establish a system capable of mass-producing 30,000 robots annually so as to deploy them across various assembly processes. Boston Dynamics says Atlas can learn most tasks within a day and autonomously handle diverse high-intensity labor, including lifting objects weighing up to 50 kilograms over 2 meters. The issue is that the deployment of humanoid robots like Atlas will likely spark employment insecurity and exacerbate inequality in the workforce. An October 2025 survey of 1,000 working Koreans nationwide aged 19 and over conducted by Gabjil 119, an activist group that battles workplace abuse, shows that one in two workers (48.2% of respondents) in Korea were afraid that they would be replaced by AI. Eight out of 10 respondents (77.9%) estimated that the spread of AI would make labor market inequality and wealth polarization even worse, pointing to growing concerns that physical AI could soon begin to replace human labor. While Atlas has sparked renewed debate on the issue, South Korea is already the world's No. 1 adopter of industrial robots. According to 2024 data from the International Federation of Robotics, South Korea had the highest robot density -- the number of robots per 10,000 employees -- in the world, at 1,012. South Korea was followed by Singapore (770), China (470), Germany (429) and Japan (419), with the global average being 162. The deployment of robots has been on the rise not only in the automotive industry, but also in sectors known for high-intensity and high-risk operations, such as shipbuilding and steel manufacturing sites. Hanwha Ocean, which has confirmed the potential of automating collaboration between human welders and robots in indoor manufacturing processes, plans to progressively double the automation rate at its shipyards, aiming for 100% automation in welding by 2030. Posco Group has also been deploying Boston Dynamics' quadruped Spot robots since 2023, using them for maintenance in areas that are difficult for humans to access, such as areas around blast furnaces. "If we maximize our current technological capabilities, it will be possible to replace human workers with robots for dangerous processes that come with high fatality rates," a shipbuilding industry official told the Hankyoreh on Sunday. "However, backlash from labor unions is prompting businesses to tread with caution while closely monitoring the discourse surrounding Hyundai Motor Group and its utilization of Atlas," they added. "As a monumental change that will change the paradigm of businesses, the deployment of humanoid robots such as Atlas in factories will cause tensions to run high between companies and labor unions. But this is also an opportunity to set the example for an exemplary negotiation," commented Lee Byoung-hoon, a professor emeritus of sociology at Chung-Ang University and expert on labor relations. "The company and the labor union must communicate and negotiate with one another to find the best outcome that will be the least detrimental to jobs and labor conditions," he emphasized. An official with the Korean Metal Workers' Union said, "The collective bargaining agreement exists to ensure that the labor union is consulted when and if changes occur in employment and work environments. The Hyundai Motor local of the union wants the management and workers to reach an agreement on the introduction of Atlas." By Lee Jae-ho, staff reporter; Yoo Ha-young, staff reporter; Park Da-hae, staff reporter

[5]

Hyundai Motor union warns against humanoid robot deployment - The Korea Times

Boston Dynamics' Atlas humanoid robots are displayed at the Hyundai Motor Group booth for CES 2026 in Las Vegas, Jan. 6. Reuters-Yonhap Hyundai Motor's labor union stated its strong opposition to the carmaker's plan for deploying humanoid robots across its major assembly lines here and abroad. "The introduction of artificial intelligence (AI) robots -- aimed at cutting labor costs -- becomes visible," the union said in a statement, Thursday. "The union warns that not a single robot can be deployed at worksites without an agreement between the union and management." Starting this year, Hyundai Motor Group has identified the Atlas humanoid robot as its next major growth engine in the burgeoning era of physical AI. The carmaker unveiled the vision during this year's CES tech fair when it displayed a concrete plan to deploy Boston Dynamics' Atlas robots to Hyundai Motor Group Metaplant America (HMGMA) by 2028. Regarding concerns over the impact on the job market, Hyundai Motor said robots will focus primarily on repetitive and dangerous tasks avoided by humans, so the deployment of humanoid robots at factories will improve the overall labor efficiency. The union, however, stepped up its negative rhetoric against the carmaker's plan, saying that mass production of robots and their deployment at worksites will deal a severe blow to its labor force. "Under no circumstances will workers welcome the plan, as the robot deployment will bring a huge employment shock," the union said. According to the union, the carmaker needs to bear continued labor costs when hiring humans, but this is not the case when manufacturing robots. "This is a good excuse for capitalists who seek to maximize profits from a long-term viewpoint," the union said. The annual maintenance cost for a humanoid robot, such as Atlas, is estimated to reach up to 14 million won ($9,500) each year, but the figure is far lower than typical labor costs. The union also criticized management for its plan to expand production capacity at its overseas plants, such as HMGMA in the United States. "For now, the plant's annual capacity is below 100,000 vehicles, but the carmaker plans to increase the figure to more than 500,000 by 2028, which is seen as the carmaker's obvious intention to relocate domestic car production to overseas factories," the union said. Hyundai Motor Group recently became the nation's third-most valuable firm by market capitalization on investors' growing optimism for its robotics vision.

Share

Share

Copy Link

Hyundai Motor's labor union has issued a stark warning against the company's plans to deploy Boston Dynamics' Atlas humanoid robots across its factories, saying the move will trigger a massive employment shock. The union vows that not a single robot can enter production sites without a labor-management agreement, setting up a confrontation that could define how AI-powered automation reshapes manufacturing in Korea and beyond.

Hyundai Labor Union Draws Line on Humanoid Robots

Hyundai Motor's labor union has taken a firm stance against the company's ambitious plans to deploy humanoid robots across its manufacturing facilities, warning that the move will bring a "huge employment shock" to workers

1

. The union issued a statement declaring that "not a single robot can be deployed at worksites without an agreement between the union and management," effectively blocking the carmaker's automation strategy until negotiations are complete5

.The conflict emerged after Hyundai Motor Group unveiled Boston Dynamics' Atlas robot at CES 2026 earlier this month, positioning Physical AI as its next major growth engine

2

. The company announced plans to build a factory capable of producing 30,000 robots annually by 2028 and begin deploying these AI-powered robot workers at Hyundai Motor Group Metaplant America (HMGMA) in Georgia that same year, with plans to roll them out across all global production sites1

.

Source: Korea Times

Cost Reduction Drives Automation Strategy

The deployment of humanoid robots represents a significant shift in manufacturing economics that has alarmed workers. The annual maintenance cost for an Atlas robot is estimated at approximately $9,500, far below typical human labor costs, which reach about 130 million won per year for each employee at Hyundai

3

. These robots can operate nearly 24 hours a day without requiring sick days, vacation time, or breaks, making them an attractive option for companies focused on cost reduction and production efficiency .

Source: TechSpot

The Hyundai labor union has accused management of using automation to reduce the workforce and maximize profits at the expense of human workers. "This is a good excuse for capitalists who seek to maximize profits from a long-term viewpoint," the union stated, characterizing the robot deployment in factories as a strategy to cut labor costs rather than improve working conditions

2

.Yellow Envelope Law Shifts Power Dynamics

The timing of this confrontation coincides with Korea's recently enacted "yellow envelope law," set to take effect in March, which fundamentally changes the balance of power between employers and unions

3

. The pro-labor legislation expands workers' rights in labor disputes and limits employers' ability to seek damages from unions over strike-related losses, giving unions more leverage in collective bargaining agreements. Under this new framework, management decisions that significantly affect working conditions—including large-scale automation projects—are recognized as matters for collective bargaining and action3

.Experts suggest this legal shift may paradoxically both slow and accelerate automation. While union rights could delay robot deployment, companies might rush to install automation before union power increases further. "The real question is not whether this will happen, but whether labor, capital and the state will use this moment to find a balance that lets us prosper together," said Ahn Jong-ki, a professor at the Korea University Institute for Research on Labor and Employment

3

.Korea Leads Global Robot Adoption

The controversy unfolds against the backdrop of Korea's position as the world's leading adopter of industrial robots. According to 2024 data from the International Federation of Robotics, South Korea had the highest robot density globally at 1,012 robots per 10,000 employees, far exceeding Singapore's 770, China's 470, Germany's 429, and the global average of 162

4

. This existing infrastructure makes Korea a natural testing ground for the next wave of humanoid automation.Boston Dynamics says Atlas can learn most tasks within a day and autonomously handle diverse high-intensity labor, including lifting objects weighing up to 50 kilograms over 2 meters

4

. Hyundai plans to phase in the robots starting in 2028 with simple tasks like parts sequencing, then deploy them for complex, heavy-duty operations across production lines by 20302

.

Source: Korea Times

Related Stories

Worker Anxiety and Workforce Inequality Concerns

The impact of automation on human labor extends beyond Hyundai's factories. An October 2025 survey of 1,000 working Koreans conducted by Gabjil 119 found that nearly half of respondents (48.2%) feared being replaced by AI, while 77.9% estimated that AI adoption would worsen labor market inequality and wealth polarization

4

. These concerns about workforce inequality highlight the broader social implications of rapid automation.Other Korean manufacturers are watching the Hyundai situation closely. Hanwha Ocean plans to progressively double automation rates at its shipyards, targeting 100% automation in welding by 2030, while Posco Group has deployed Boston Dynamics' Spot robots since 2023 for maintenance in hazardous areas

4

. "Backlash from labor unions is prompting businesses to tread with caution while closely monitoring the discourse surrounding Hyundai Motor Group and its utilization of Atlas," a shipbuilding industry official noted4

.What Comes Next

Hyundai's 2028 timeline may already represent a compromise designed to test union and public reaction rather than the earliest technically feasible deployment date, according to labor experts

3

. The company has emphasized that Atlas will ease the physical burden on workers and handle dangerous tasks, but the union remains unconvinced that warnings of mass job losses can be dismissed1

.Lee Byoung-hoon, a professor emeritus of sociology at Chung-Ang University, characterized the situation as "an opportunity to set the example for an exemplary negotiation," urging both sides to communicate and find outcomes that minimize harm to jobs and labor conditions

4

. Whether this labor-management agreement can be reached will likely shape how manufacturing automation proceeds not just in Korea, but globally, as other companies observe whether aggressive robot deployment strategies can overcome organized labor resistance in an era of strengthened union rights.References

Summarized by

Navi

[2]

Related Stories

Boston Dynamics' Atlas robot enters production to build Hyundai cars starting in 2028

05 Jan 2026•Technology

Hyundai's Boston Dynamics Atlas humanoid robot drives 14% stock surge with factory plans

07 Jan 2026•Technology

Boston Dynamics unveils production-ready Atlas robot with superhuman abilities at CES 2026

05 Jan 2026•Technology

Recent Highlights

1

ByteDance's Seedance 2.0 AI video generator triggers copyright infringement battle with Hollywood

Policy and Regulation

2

Microsoft AI chief predicts artificial intelligence will automate most white-collar jobs in 18 months

Business and Economy

3

Anthropic and Pentagon clash over AI safeguards as $200 million contract hangs in balance

Policy and Regulation