PepsiCo partners with Nvidia and Siemens on AI collaboration to transform manufacturing operations

2 Sources

2 Sources

[1]

PepsiCo announces industrial AI collaboration with Nvidia and Siemens (PEP:NASDAQ)

New! Get unlimited breaking news with a free Seeking Alpha account " PepsiCo (PEP) announced at CES that the company struck a multi-year, industry-first collaboration with Siemens and Nvidia (NVDA) to deploy advanced AI and physics-based digital twin technology to transform its manufacturing plants and supply chain operations. The collaboration will start with pilot facilities in the U.S. and scale globally over time. The partnership uses Siemens' new Digital Twin Composer built on the Nvidia (NVDA) Omniverse platform to create high-fidelity 3D simulations of every machine, conveyor, pallet route, and operator path. The platform is expected to help PepsiCo (PEP) virtually design, test, and optimize facility layouts before making physical changes. Notably, the industrial metaverse environments combine 2D and 3D digital twin data with real-time operational information, allowing AI agents to identify up to 90% of potential issues in advance, accelerate design cycles, and uncover hidden capacity. Early deployments have reportedly delivered a 20% increase in throughput, nearly 100% design validation, and 10-15% reductions in capital expenditure by validating investments in a virtual environment rather than through traditional, slower, and more costly physical expansion. "We are deploying the first digital blueprint that reimagines how the supply chain is designed, built, and scaled, a first for the industry," stated Athina Kanioura, CEO, Latin America, and Global Chief Strategy & Transformation Officer of PepsiCo. "With a unified, AI-powered digital foundation, PepsiCo is building toward a world where every plant and warehouse operates as part of a single, intelligent ecosystem. In this future, our facilities don't just respond to demand; they anticipate and then adapt to it," added Kanioura. Analysts have highlighted the announcement as one of the biggest from a consumer company at CES this year. More on Pepsico Top 10 'Strong Buy'-rated Stocks for 2026 In this new report, our VP of Quantitative Strategy analyzes Seeking Alpha's Top Stocks for 2026. In 2025 alone, the Top 10 Stocks returned 50.84% vs. 16.94% for the S&P 500.* Access the report now and explore this year's high-potential stocks. *Performance as of November 28, 2025. Past performance is no guarantee for future results. Today's chaos. Tomorrow's opportunity Seeking Alpha helps you make sense of the headlines. New! Get unlimited breaking stock news for free -- so you can stay on track for a stronger financial future.

[2]

PepsiCo Announces Industry-First AI and Digital Twin Collaboration with Siemens and NVIDIA

Together, PepsiCo, Siemens, and NVIDIA will set a new standard for scalable, technically sound digital twin and AI in industrial operations. LAS VEGAS and PURCHASE, N.Y., Jan. 6, 2026 /PRNewswire/ -- At CES 2026, PepsiCo (NASDAQ: PEP) announced a multi-year, industry-first collaboration with Siemens and NVIDIA to transform plant and supply chain operations through advanced digital twin technology and AI. This collaboration marks a first-of-its-kind initiative for a global CPG company applying digital twins to reshape how plant and warehousing facilities are digitally simulated and tested, with early pilots already underway in the U.S. With demand for production and distribution capacity rising, PepsiCo is using AI and new digital approaches to process simulation and facility design to retool and optimize its existing physical footprint. Traditional expansion methods are slow and costly, limiting flexibility and the scalability needed to meet growing consumer needs while driving innovation. "The scale and complexity of PepsiCo's business, from farm to shelf, is massive -- and we are embedding AI throughout our operations to better meet the increasing demands of our consumers and customers," said Ramon Laguarta, Chairman and CEO of PepsiCo. "Our work with Siemens and NVIDIA will help accelerate our continued journey of becoming a future-fit company, operating with agility and foresight." PepsiCo is shifting to a digital-first planning strategy, leveraging physics-based digital twins and AI agents as co-designers to simulate, validate, and optimize facility layouts before any physical build. As part of these efforts, PepsiCo is using Siemens Digital Twin Composer, built on NVIDIA Omniverse libraries, to simulate upgrades to its facilities in the U.S. with plans to scale globally. "Physical industries are entering the age of AI. For companies with real-world assets, digital twins are the foundation of their AI journey," said Jensen Huang, founder and CEO of NVIDIA. "Working with NVIDIA and Siemens, PepsiCo is re-architecting its operations -- using physically accurate digital twins and AI to reinvent how it designs, optimizes, and runs its global operations." "We are proud to partner with PepsiCo and NVIDIA to digitally transform their manufacturing facilities using physics-based digital twins and AI from design to engineering to operations. The Digital Twin Composer is a cornerstone in enabling PepsiCo to transform manufacturing and warehousing," said Roland Busch, CEO of Siemens AG. "Siemens is powering the industrial AI revolution - with an unmatched industrial AI technology stack, deep domain knowhow, and world-class partners. This collaboration sets a new standard for all industries. Customers can turn ideas into real-world impact with greater speed, quality, and efficiency." Siemens' new software solution builds Industrial Metaverse environments at scale, empowering organizations to apply industrial AI, simulation and real-time physical data to make decisions virtually, at speed and at scale. This new product enables industrial companies to combine 2D and 3D digital twin data from Siemens' comprehensive digital twin and physical real-time information from a managed, secure real-time photorealistic virtual scene accelerated by NVIDIA Omniverse libraries. With Digital Twin Composer, companies can rapidly build and maintain this global environment, containing all aspects of their product or production data (both virtual and physical) in a secure, managed, high-fidelity 3D experience throughout the lifecycle of the product, process or facility. PepsiCo and Siemens are digitally transforming select U.S. manufacturing and warehouse facilities by converting them into high-fidelity 3D digital twins that simulate plant operations and the end-to-end supply chain to establish a performance baseline. Within weeks, teams optimized and validated new configurations to boost capacity and throughput, giving PepsiCo a unified, real-time view of operations with flexibility to integrate AI-driven capabilities over time. Leveraging Siemens' Digital Twin Composer, NVIDIA Omniverse and computer vision, PepsiCo can now recreate every machine, conveyor, pallet route and operator path with physics-level accuracy, enabling AI agents to simulate, test, and refine system changes - identifying up to 90 percent of potential issues before any physical modifications occur. This approach has already delivered a 20 percent increase in throughput on initial deployment and is driving faster design cycles, nearly 100 percent design validation and 10 to 15 percent reductions in capital expenditure (Capex) by uncovering hidden capacity and validating investments in a virtual environment. "We are deploying the first digital blueprint that reimagines how the supply chain is designed, built, and scaled, a first for the industry," says Athina Kanioura, CEO, Latin America, and Global Chief Strategy & Transformation Officer of PepsiCo. "With a unified, AI-powered digital foundation, PepsiCo is building toward a world where every plant and warehouse operates as part of a single, intelligent ecosystem. In this future, our facilities don't just respond to demand, they anticipate and then adapt to it." Announcement at CES 2026 This partnership was formally announced during the opening keynote at CES 2026, highlighting PepsiCo's commitment to digital transformation and supply chain innovation. The collaboration brings together Siemens' Industrial AI expertise and comprehensive digital twin technology with NVIDIA's AI and visualization expertise to set a new standard for the industry. About PepsiCo PepsiCo products are enjoyed by consumers more than one billion times a day in more than 200 countries and territories around the world. PepsiCo generated nearly $92 billion in net revenue in 2024, driven by a complementary drinks and convenient foods portfolio that includes Lay's, Doritos, Cheetos, Gatorade, Pepsi-Cola, Mountain Dew, Quaker and SodaStream. PepsiCo's product portfolio includes a wide range of enjoyable foods and drinks, including many iconic brands that generate more than $1 billion each in estimated annual retail sales. Guiding PepsiCo is our vision to Be the Global Leader in Drinks and Convenient Foods by Winning with pep+ (PepsiCo Positive). pep+ is our strategic end-to-end transformation that places sustainability at the center of our business strategy, seeking to drive growth and build a stronger, more resilient future for PepsiCo and the communities where we operate. For more information, visit www.pepsico.com, and follow on X (Twitter), Instagram, Facebook, and LinkedIn @PepsiCo. Contact: [email protected] View original content to download multimedia:https://www.prnewswire.com/news-releases/pepsico-announces-industry-first-ai-and-digital-twin-collaboration-with-siemens-and-nvidia-302653851.html

Share

Share

Copy Link

PepsiCo announced a multi-year industrial AI collaboration with Siemens and Nvidia at CES 2026, deploying Digital Twin technology to revolutionize manufacturing plants and supply chain operations. Early pilots show a 20% throughput increase, nearly 100% design validation, and 10-15% reductions in capital expenditure by simulating facility changes virtually before physical implementation.

PepsiCo Unveils Industry-First Industrial AI Collaboration

PepsiCo announced at CES 2026 a multi-year industrial AI collaboration with Siemens and Nvidia that marks a significant shift in how consumer goods companies approach manufacturing plants and plant and supply chain operations

1

2

. The partnership deploys physics-based digital twin technology to create high-fidelity 3D simulations of entire facilities, enabling the company to virtually design, test, and optimize facility layouts before making costly physical changes. Analysts have highlighted this announcement as one of the biggest from a consumer company at CES this year, signaling a new era where traditional manufacturing constraints give way to digital-first planning strategies1

.

Source: Seeking Alpha

How Siemens Digital Twin Composer and Nvidia Omniverse Platform Work Together

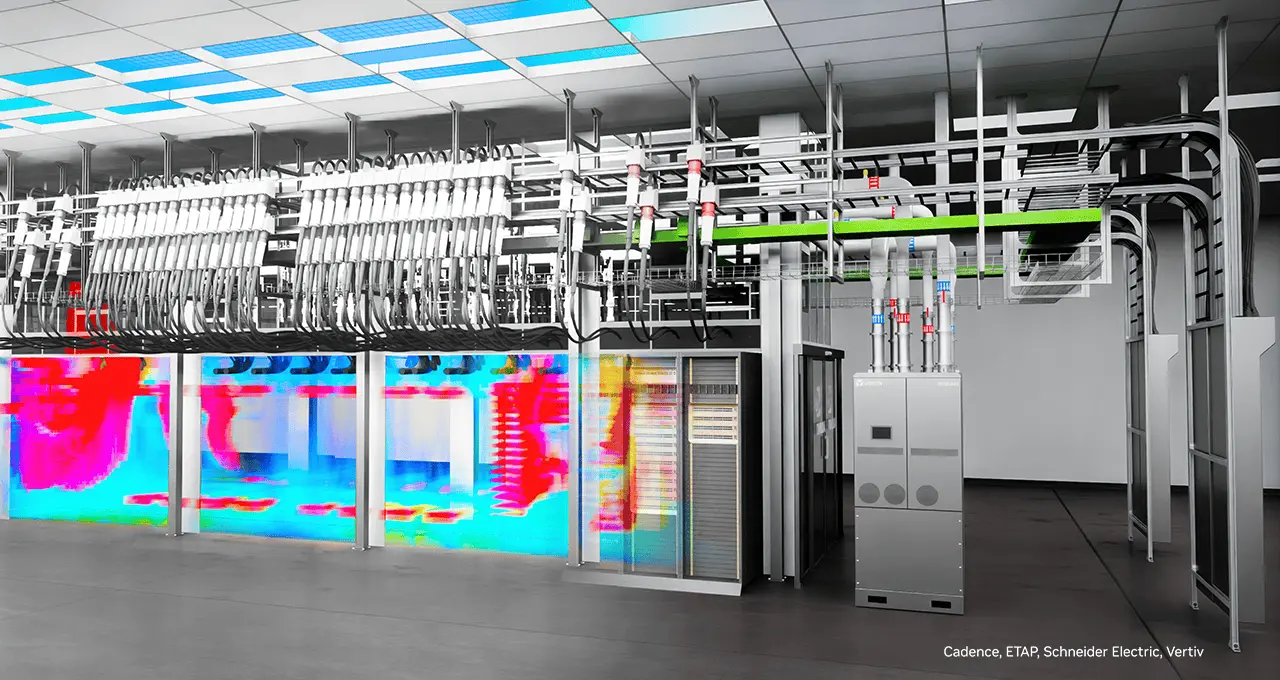

The collaboration leverages Siemens Digital Twin Composer built on the Nvidia Omniverse platform to create Industrial Metaverse environments that combine 2D and 3D digital twin data with real-time operational information

2

. This AI-powered digital foundation recreates every machine, conveyor, pallet route, and operator path with physics-level accuracy, allowing AI agents to simulate, test, and refine system changes before any physical modifications occur2

. The platform enables companies to identify up to 90% of potential issues in advance, dramatically accelerating design cycles and uncovering hidden capacity within existing infrastructure1

. Jensen Huang, founder and CEO of Nvidia, stated that "Physical industries are entering the age of AI. For companies with real-world assets, digital twins are the foundation of their AI journey"2

.Measurable Impact on Throughput and Capital Expenditure

Early deployments at pilot facilities in the U.S. have delivered compelling results that demonstrate the practical value of Digital Twin technology in manufacturing operations. The collaboration has achieved a 20% increase in throughput on initial deployment, nearly 100% design validation, and 10-15% reductions in capital expenditure by validating investments in a virtual environment rather than through traditional, slower, and more costly physical expansion

1

2

. Within weeks, teams optimized and validated new configurations to boost capacity, giving PepsiCo a unified, real-time view of operations with flexibility to integrate AI-driven capabilities over time2

. These efficiency gains matter significantly as demand for production and distribution capacity continues rising, while traditional expansion methods remain slow and limit the scalability needed to meet growing consumer needs2

.Related Stories

Building an Intelligent Ecosystem for Supply Chain Innovation

Athina Kanioura, CEO of Latin America and Global Chief Strategy & Transformation Officer of PepsiCo, described the initiative as "the first digital blueprint that reimagines how the supply chain is designed, built, and scaled, a first for the industry"

1

. She emphasized that PepsiCo is building toward a world where every plant and warehouse operates as part of a single, intelligent ecosystem where facilities don't just respond to demand but anticipate and adapt to it1

. Ramon Laguarta, Chairman and CEO of PepsiCo, noted that the scale and complexity of the company's business from farm to shelf is massive, and embedding AI throughout operations helps better meet the increasing demands of consumers and customers2

.What This Means for Manufacturing and Digital Transformation

The collaboration with pilot facilities starting in the U.S. and scaling globally over time sets a new standard for how industrial companies can apply digital transformation to manufacturing challenges

1

2

. Roland Busch, CEO of Siemens AG, stated that "Siemens is powering the industrial AI revolution - with an unmatched industrial AI technology stack, deep domain knowhow, and world-class partners. This collaboration sets a new standard for all industries"2

. For other manufacturers watching this space, the ability to conduct 3D simulations with near-perfect design validation before committing capital represents a fundamental shift in how companies can manage risk and accelerate innovation. The short-term implications include immediate cost savings and efficiency gains, while the long-term vision points toward fully autonomous, self-optimizing manufacturing networks that continuously adapt to market conditions without human intervention.References

Summarized by

Navi

Related Stories

Siemens and NVIDIA expand partnership to build AI-driven manufacturing sites launching in 2026

06 Jan 2026•Technology

NVIDIA Unveils 'Mega' Omniverse Blueprint for Revolutionizing Warehouse Robotics

07 Jan 2025•Technology

NVIDIA Unveils AI Innovations for Retail, Robotics, and Autonomous Vehicles at CES 2025

07 Jan 2025•Technology

Recent Highlights

1

Pentagon threatens to cut Anthropic's $200M contract over AI safety restrictions in military ops

Policy and Regulation

2

ByteDance's Seedance 2.0 AI video generator triggers copyright infringement battle with Hollywood

Policy and Regulation

3

OpenAI closes in on $100 billion funding round with $850 billion valuation as spending plans shift

Business and Economy