Soft Ceramic Sensors: Revolutionizing Robotics and Human-Machine Interaction

3 Sources

3 Sources

[1]

Sensitive ceramics for soft robotics

Soft ceramics -- how is that supposed to work? Materials scientists like Clemens define ceramics as an inorganic, non-metallic material that is produced from a collection of loose particles in a high-temperature process known as sintering. The composition of ceramics can vary -- and their properties change as a result. But earthenware and porcelain are nowhere to be seen in Clemens' lab. The researchers work with materials such as potassium sodium niobate and zinc oxide, but also with carbon particles. None of these materials are soft. In order to fashion them into flexible sensors, the researchers embed ceramic particles in stretchable plastics. "We work with so-called highly filled systems," says Clemens. "We take a matrix made of a thermoplastic and fill it with as many ceramic particles as possible without compromising the elasticity of the matrix." If this highly filled matrix is then stretched, compressed or exposed to temperature fluctuations, the distance between the ceramic particles changes, and with it the electrical conductivity of the sensor. It's not necessary to fill the entire matrix with ceramic, emphasizes Clemens: Using 3D printing, the researchers can also embed the ceramic sensors as a kind of "nerves" in flexible components. Selective and intelligent The production of soft ceramic sensors is not trivial. Usually, soft sensors are sensitive to different environmental influences at the same time, such as temperature, strain and humidity. "If you want to use them in practice, you need to know what you are measuring," says Clemens. His research group has succeeded in producing soft sensors that react very selectively only to pressure or only to temperature. The researchers integrated these sensors into a prosthetic hand. The prosthesis "senses" the flexion of its fingers and notices when it touches a hot surface. Such "sensitivity" would be an advantage both for robotic gripping tools and for human prostheses. The Empa team even went one step further with the development of a soft "robot skin." Similar to human skin, the multi-layered plastic skin reacts to touch and temperature differences. In order to evaluate the complex data, the Empa researchers developed an AI model together with researchers from the University of Cambridge and trained it using data from around 4,500 measurements. This is also reminiscent of human perception, as the nerve impulses from our skin are evaluated and extrapolated in the brain. In their most recent project, the researchers were able to combine the ceramic sensors with artificial muscles. Together with researchers from ETH Zurich and the University of Tokyo, they have developed a bio-hybrid robot that recognizes its contraction state with the help of a soft, biocompatible, tissue-integrated piezoresistive sensor. This work was published in the journal Advanced Intelligent Systems. Safe collaboration between humans and machines The aim, says Frank Clemens, is for humans and machines to work together safely and harmoniously. "Today's robotic systems are big, clunky and very strong. They can be dangerous for humans," explains the researcher. If in future we are to increasingly share our workplaces with robots, they should react quickly and sensitively to touch. "If you accidentally touch another person, you automatically pull away," says Clemens. "We want to give robots the same reflex." The researchers are now looking for industrial partners in the field of robotic gripping systems. But soft sensors are also in demand in medicine -- the team recently completed an Innosuisse project with the company IDUN Technologies, in which they produced flexible electrodes for brain wave measurements. The work is far from over: The researchers want to make their soft ceramic sensors even more sensitive and intelligent. This involves combining new ceramic materials and soft polymers and optimizing their sensor properties. The secret to success lies in the interaction of these two components.

[2]

Sensitive ceramics for soft robotics: Developing soft and intelligent sensor materials based on ceramic particles

by Anna Ettlin , Swiss Federal Laboratories for Materials Science and Technology Most people think of coffee cups, bathroom tiles or flower pots when they hear the word "ceramic." Not so Frank Clemens. For the research group leader in Empa's Laboratory for High-Performance Ceramics, ceramics can conduct electricity, be intelligent, and even feel. Together with his team, Clemens is developing soft sensor materials based on ceramics. Such sensors can "feel" temperature, strain, pressure or humidity, for instance, which makes them interesting for use in medicine, but also in the field of soft robotics. This work was published in the journal Advanced Intelligent Systems. Soft ceramics -- how is that supposed to work? Materials scientists like Clemens define ceramics as an inorganic, non-metallic material that is produced from a collection of loose particles in a high-temperature process known as sintering. The composition of ceramics can vary -- and their properties change as a result. But earthenware and porcelain are nowhere to be seen in Clemens' lab. The researchers work with materials such as potassium sodium niobate and zinc oxide, but also with carbon particles. None of these materials are soft. In order to fashion them into flexible sensors, the researchers embed ceramic particles in stretchable plastics. "We work with so-called highly filled systems," says Clemens. "We take a matrix made of a thermoplastic and fill it with as many ceramic particles as possible without compromising the elasticity of the matrix." If this highly filled matrix is then stretched, compressed or exposed to temperature fluctuations, the distance between the ceramic particles changes, and with it the electrical conductivity of the sensor. It's not necessary to fill the entire matrix with ceramic, emphasizes Clemens: Using 3D printing, the researchers can also embed the ceramic sensors as a kind of "nerves" in flexible components. Selective and intelligent The production of soft ceramic sensors is not trivial. Usually, soft sensors are sensitive to different environmental influences at the same time, such as temperature, strain and humidity. "If you want to use them in practice, you need to know what you are measuring," says Clemens. His research group has succeeded in producing soft sensors that react very selectively only to pressure or only to temperature. The researchers integrated these sensors into a prosthetic hand. The prosthesis "senses" the flexion of its fingers and notices when it touches a hot surface. Such "sensitivity" would be an advantage both for robotic gripping tools and for human prostheses. The Empa team even went one step further with the development of a soft "robot skin." Similar to human skin, the multi-layered plastic skin reacts to touch and temperature differences. In order to evaluate the complex data, the Empa researchers developed an AI model together with researchers from the University of Cambridge and trained it using data from around 4,500 measurements. This is also reminiscent of human perception, as the nerve impulses from our skin are evaluated and extrapolated in the brain. In their most recent project, the researchers were able to combine the ceramic sensors with artificial muscles. Together with researchers from ETH Zurich and the University of Tokyo, they have developed a bio-hybrid robot that recognizes its contraction state with the help of a soft, biocompatible, tissue-integrated piezoresistive sensor. Safe collaboration between humans and machines The aim, says Frank Clemens, is for humans and machines to work together safely and harmoniously. "Today's robotic systems are big, clunky and very strong. They can be dangerous for humans," explains the researcher. If in future we are to increasingly share our workplaces with robots, they should react quickly and sensitively to touch. "If you accidentally touch another person, you automatically pull away," says Clemens. "We want to give robots the same reflex." The researchers are now looking for industrial partners in the field of robotic gripping systems. But soft sensors are also in demand in medicine -- the team recently completed an Innosuisse project with the company IDUN Technologies, in which they produced flexible electrodes for brain wave measurements. The work is far from over: The researchers want to make their soft ceramic sensors even more sensitive and intelligent. This involves combining new ceramic materials and soft polymers and optimizing their sensor properties. The secret to success lies in the interaction of these two components.

[3]

Sensitive ceramics for soft robotics | Newswise

Empa researcher Christopher Bascucci demonstrates a soft material which can be enhanced with ceramic sensors. Most people think of coffee cups, bathroom tiles or flower pots when they hear the word "ceramic". Not so Frank Clemens. For the research group leader in Empa's Laboratory for High-Performance Ceramics, ceramics can conduct electricity, be intelligent, and even feel. Together with his team, Clemens is developing soft sensor materials based on ceramics. Such sensors can "feel" temperature, strain, pressure or humidity, for instance, which makes them interesting for use in medicine, but also in the field of soft robotics. Soft ceramics - how is that supposed to work? Materials scientists like Clemens define ceramics as an inorganic, non-metallic material that is produced from a collection of loose particles in a high-temperature process known as sintering. The composition of ceramics can vary - and their properties change as a result. But earthenware and porcelain are nowhere to be seen in Clemens' lab. The researchers work with materials such as potassium sodium niobate and zinc oxide, but also with carbon particles. None of these materials are soft. In order to fashion them into flexible sensors, the researchers embed ceramic particles in stretchable plastics. "We work with so-called highly filled systems," says Clemens. "We take a matrix made of a thermoplastic and fill it with as many ceramic particles as possible without compromising the elasticity of the matrix." If this highly filled matrix is then stretched, compressed or exposed to temperature fluctuations, the distance between the ceramic particles changes, and with it the electrical conductivity of the sensor. It's not necessary to fill the entire matrix with ceramic, emphasizes Clemens: Using 3D printing, the researchers can also embed the ceramic sensors as a kind of "nerves" in flexible components. Selective and intelligent The production of soft ceramic sensors is not trivial. Usually, soft sensors are sensitive to different environmental influences at the same time, such as temperature, strain and humidity. "If you want to use them in practice, you need to know what you are measuring," says Clemens. His research group has succeeded in producing soft sensors that react very selectively only to pressure or only to temperature. The researchers integrated these sensors into a prosthetic hand. The prosthesis "senses" the flexion of its fingers and notices when it touches a hot surface. Such "sensitivity" would be an advantage both for robotic gripping tools and for human prostheses. The Empa team even went one step further with the development of a soft "robot skin". Similar to human skin, the multi-layered plastic skin reacts to touch and temperature differences. In order to evaluate the complex data, the Empa researchers developed an AI model together with researchers from the University of Cambridge and trained it using data from around 4,500 measurements. This is also reminiscent of human perception, as the nerve impulses from our skin are evaluated and extrapolated in the brain. In their most recent project, the researchers were able to combine the ceramic sensors with artificial muscles. Together with researchers from ETH Zurich and the University of Tokyo, they have developed a bio-hybrid robot that recognizes its contraction state with the help of a soft, biocompatible, tissue-integrated piezoresistive sensor. This work was published in the journal Advanced Intelligent Systems. Safe collaboration between humans and machines The aim, says Frank Clemens, is for humans and machines to work together safely and harmoniously. "Today's robotic systems are big, clunky and very strong. They can be dangerous for humans," explains the researcher. If in future we are to increasingly share our workplaces with robots, they should react quickly and sensitively to touch. "If you accidentally touch another person, you automatically pull away," says Clemens. "We want to give robots the same reflex." The researchers are now looking for industrial partners in the field of robotic gripping systems. But soft sensors are also in demand in medicine - the team recently completed an Innosuisse project with the company IDUN Technologies, in which they produced flexible electrodes for brain wave measurements. The work is far from over: The researchers want to make their soft ceramic sensors even more sensitive and intelligent. This involves combining new ceramic materials and soft polymers and optimizing their sensor properties. The secret to success lies in the interaction of these two components.

Share

Share

Copy Link

Researchers at Empa develop innovative soft ceramic sensors for use in robotics and medicine, paving the way for safer human-machine collaboration and more sensitive prosthetics.

Redefining Ceramics for Soft Robotics

Researchers at Empa's Laboratory for High-Performance Ceramics, led by Frank Clemens, are challenging traditional notions of ceramics by developing soft, intelligent sensor materials. These innovative sensors can detect temperature, strain, pressure, and humidity, opening up new possibilities in medicine and soft robotics

1

2

3

.The Science Behind Soft Ceramics

Contrary to conventional ceramics, the team works with materials like potassium sodium niobate, zinc oxide, and carbon particles. To create flexible sensors, they embed ceramic particles in stretchable plastics, forming what Clemens calls "highly filled systems." This matrix of thermoplastic and ceramic particles changes its electrical conductivity when stretched, compressed, or exposed to temperature fluctuations

1

2

.Selective Sensing and Prosthetic Applications

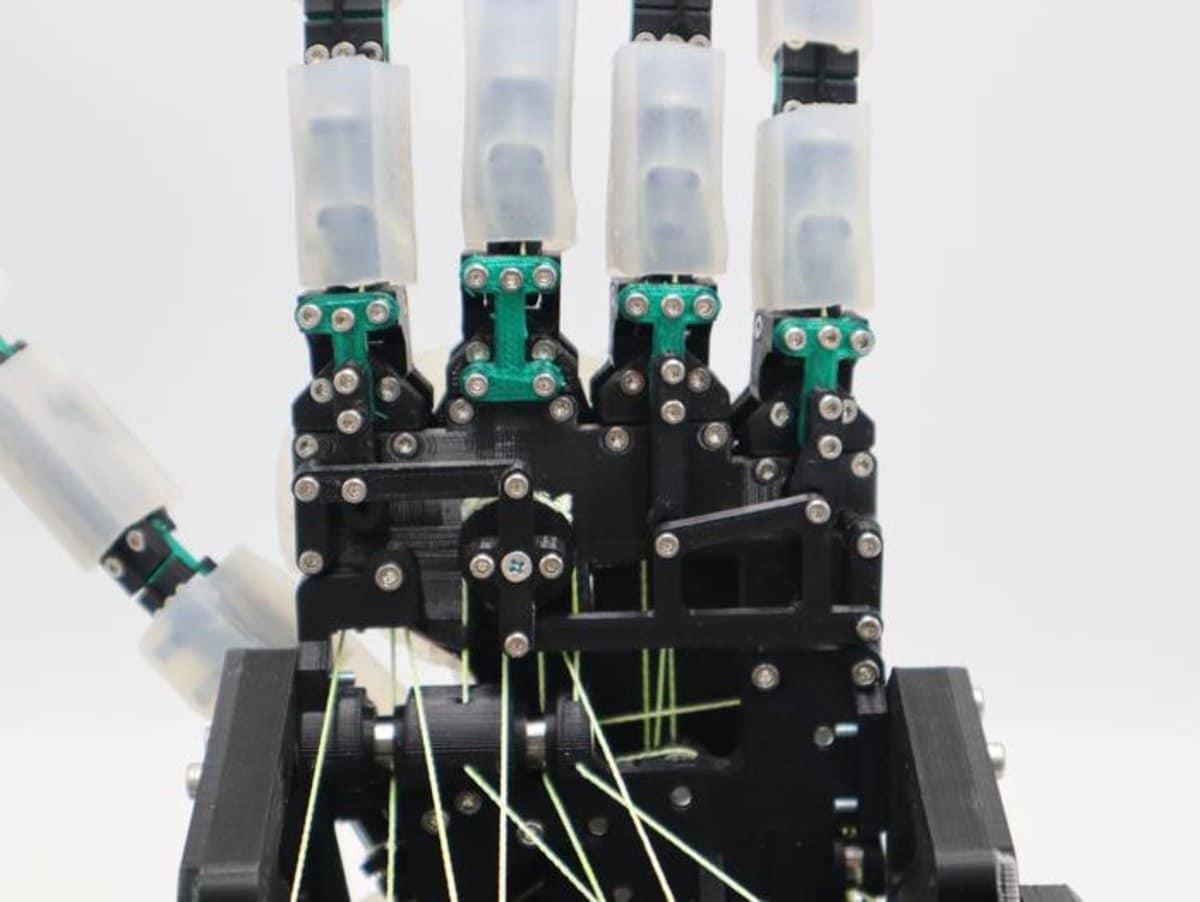

One of the key achievements of Clemens' team is the development of sensors that react selectively to specific stimuli. They have successfully created soft sensors that respond exclusively to pressure or temperature. These sensors have been integrated into a prosthetic hand, enabling it to "sense" finger flexion and detect hot surfaces, potentially enhancing both robotic gripping tools and human prostheses

1

2

3

.Advanced "Robot Skin" and AI Integration

The research team has taken a significant step forward by developing a soft "robot skin." This multi-layered plastic skin mimics human skin in its ability to react to touch and temperature differences. To process the complex data from this skin, the researchers collaborated with the University of Cambridge to develop an AI model, trained on approximately 4,500 measurements. This approach mirrors human perception, where skin nerve impulses are evaluated and extrapolated in the brain

1

2

3

.Bio-Hybrid Robots and Artificial Muscles

In a recent project, the team combined their ceramic sensors with artificial muscles. Working with researchers from ETH Zurich and the University of Tokyo, they created a bio-hybrid robot capable of recognizing its contraction state using a soft, biocompatible, tissue-integrated piezoresistive sensor. This groundbreaking work was published in the journal Advanced Intelligent Systems

1

2

3

.Related Stories

Towards Safer Human-Machine Collaboration

The ultimate goal of this research is to enable safe and harmonious collaboration between humans and machines. Clemens emphasizes the need for robots that can react quickly and sensitively to touch, especially as humans and robots increasingly share workspaces. The team aims to give robots a reflex similar to humans, where accidental contact results in an immediate withdrawal

1

2

3

.Future Directions and Applications

While seeking industrial partners in robotic gripping systems, the researchers are also exploring medical applications. They recently completed an Innosuisse project with IDUN Technologies, producing flexible electrodes for brain wave measurements. The team continues to work on making their soft ceramic sensors more sensitive and intelligent, focusing on the combination of new ceramic materials and soft polymers

1

2

3

.References

Summarized by

Navi

[1]

[2]

[3]

Related Stories

Robotic Hand Mimics Human-Like Grasp with Innovative Compliant Design

14 May 2025•Science and Research

SonicSense: Robots Gain Human-Like Perception Through Acoustic Vibrations

23 Oct 2024•Science and Research

Breakthrough in Robotics: Electricity-Free Circuits Enable More Advanced AI Integration

10 Oct 2024•Technology

Recent Highlights

1

Google Gemini 3.1 Pro doubles reasoning score, beats rivals in key AI benchmarks

Technology

2

ByteDance's Seedance 2.0 AI video generator triggers copyright infringement battle with Hollywood

Policy and Regulation

3

ChatGPT cracks decades-old gluon amplitude puzzle, marking AI's first major theoretical physics win

Science and Research