AI-Driven Design of Super-Adhesive Hydrogels Inspired by Nature

4 Sources

4 Sources

[1]

Nature - Rubber stuck

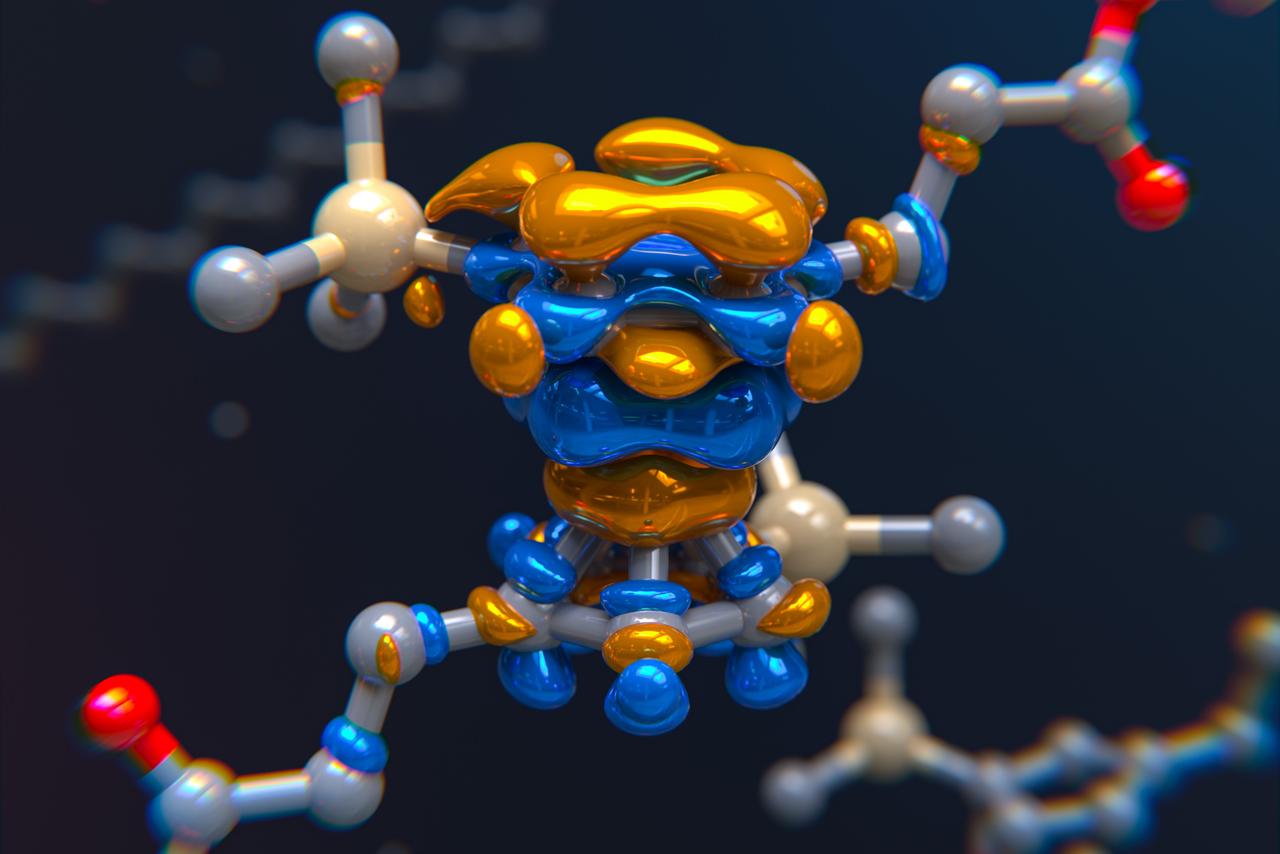

Designing adhesives that remain effective in wet environments is a formidable challenge that can even confound approaches that use artificial intelligence. In this week's issue, Jian Ping Gong and colleagues draw inspiration from nature to develop a data-driven system that analyses adhesive protein sequences and then employs AI to create super-adhesive materials that can withstand water. The researchers mined a data set of 24,707 naturally occurring adhesive proteins to guide the design of 180 hydrogels. Using an iterative machine-learning framework, they optimized adhesion performance and identified a set of promising super-adhesive hydrogels. One of these, a hydrogel named R1-max, was synthesized and tested by gluing a rubber duck to a rock in the ocean (pictured on the cover), where it readily withstood waves and tides. Cover image: Hao Guo, Hongguang Liao and Hailong Fan.

[2]

AI learns from nature to design super-adhesive gels that work underwater

Super-sticky hydrogels that can be used in wet environments are needed for many applications -- for example, as glues to seal tissue and stop bleeding in surgery, as gels that support wound healing and tissue regeneration, and as materials used underwater on ships and offshore structures. However, designing such hydrogels is difficult because the properties that make materials soft are often the opposite of those that promote adhesion. Moreover, the conventional approach for discovering functional hydrogels (those that have specific properties needed for an application) is essentially trial and error. This is expensive and time-consuming, and has therefore strongly limited the development of materials that can be translated to clinical or industrial applications. Writing in Nature, Liao et al. report an innovative solution in which artificial intelligence (AI) supports the design of super-adhesive hydrogels. AI approaches known as machine learning and deep learning have previously been used to identify hard, inorganic materials with specific properties. For example, a deep-learning platform has been used to discover millions of materials that form stable crystals, providing information that enables previously impossible computational modelling of the materials' properties. Machine learning has also been combined with robotic systems to develop and implement syntheses of compounds that were computationally identified by AI. However, hard, inorganic materials typically have well-defined structures and properties, arguably simplifying the process of training and using AI to identify them. By contrast, computationally identifying hydrogels suitable for a specific function is a much more complex task, for several reasons. One issue is that the polymeric molecules found in functional hydrogels can contain a variety of chemical groups. Another is that the properties of hydrogels are influenced by several factors, such as the secondary structure (the local spatial arrangement) of molecules, the ability of the molecules to adopt different conformations and the interactions between the molecules. The rheological properties of hydrogels -- how they deform and flow under stress -- must also be tailored for real-world applications. A further issue that specifically affects hydrogels in wet environments is that hydrogels typically swell when they absorb water, and this swelling behaviour must be considered. Another problem is that large data sets are typically needed to train AI platforms to predict the properties of materials, but very few data describing the multiple chemical and physical parameters that influence hydrogel properties have been reported. AI has therefore been used to predict only the characteristics of hydrogels that are important for their formulation and manufacture -- such as swelling behaviour and suitability for 3D printing. Nevertheless, these studies demonstrate how AI can be used to guide the research and development of soft materials and thereby reduce the experimental efforts needed. Liao et al. now report a data-driven approach for designing super-adhesive hydrogels, inspired by nature. The authors analysed the amino-acid sequences of proteins used as adhesives in underwater biological systems to determine the characteristic features of these natural glues (Fig. 1). They then used this analysis to guide the design of 180 hydrogels, the molecular building blocks of which were chosen to replicate the features identified in the natural adhesives. The authors synthesized these hydrogels and measured their underwater adhesive strengths, rheological properties and swelling behaviour. This provided a data set that was sufficiently diverse to train machine-learning tools that could propose further designs and predict the underwater adhesive strengths. Liao et al. then used an iterative optimization process in which the designs with the highest predicted adhesion strengths were synthesized and tested, and the resulting data used to inform another round of machine-learning-driven design. The best hydrogels from each of three rounds of design were all found to have adhesive strength underwater much superior to that of the original set of 180 proteins. The authors tested the three best hydrogels in different wet environments, which demonstrated that these materials have excellent adhesive properties. Moreover, the hydrogels could maintain strong adhesion for long periods (more than a year, in one experiment), and were found to be stable in both static and dynamic environments. For example, one of the hydrogels was used to glue a rubber duck to a rock by the sea -- the duck remained fixed to the rock despite continuous wave impacts and the passage of tides (Fig. 2). Another hydrogel was used to patch a 20-millimetre-diameter hole at the base of a 3-metre-tall pipe filled with water. The patch instantly stopped a high-pressure leak, and continued to seal the hole without being compromised for more than five months. Experiments in which the hydrogels were implanted beneath the skin of mice also showed that these materials are biocompatible. Super-adhesive hydrogels such as these that stick strongly to irregular and wet surfaces could be transformational for many biomedical applications, including prosthesis coatings and wearable biosensors. Such hydrogels might also find applications in industrial or environmental contexts in which stable, strong adhesion under wet conditions is essential. Liao and colleagues' approach to designing functional hydrogels is versatile; it could be adapted for other types of functional soft materials, and even be automated using robotics in research laboratories. Some challenges will need to be addressed. For example, it remains to be seen whether the method will cope with the large structural diversity of polymers used in biomedical and other applications. AI methods will need to be developed that can combine data relevant at different scales (such as data that describe the microscopic and macroscopic properties of materials), and which maintain performance when modelling more-complex systems using much larger amounts of data. However, Liao and colleagues' findings provide a good basis to overcome these challenges. More broadly, the authors' work demonstrates that AI is no longer just being tentatively scoped out as a tool for materials science -- it has already been adopted to improve and support the design and generation of materials, actively changing the way in which scientists approach their research.

[3]

Super-sticky hydrogel is 10 times stronger than other glues underwater

Researchers analysed thousands of natural protein sequences and got assistance from AI in order to design a new hydrogel adhesive that can stay sticky underwater or even within a living body A rubber duck that was stuck to a seaside rock for more than a year has proved the strength of a new sticky material. The adhesive could be used in deep-sea robots and repair work, or as surgical glue for medical procedures. "We developed a super-adhesive hydrogel that works extremely well even underwater - something very few materials can achieve," says Hailong Fan at Shenzhen University in China. Hydrogels are stretchy and soft materials. Fan, then at Hokkaido University in Japan, and his colleagues analysed 24,000 sticky protein sequences from many different organisms to identify the stickiest combinations of amino acids, the building blocks of proteins. They used that information to create 180 different types of adhesive hydrogel. Then, they trained artificial intelligence models on the hydrogels' material properties to predict even better recipes for super-sticky materials. This process let the team develop a new class of versatile and sticky hydrogel. The material bonds to surfaces even when it has been unstuck and restuck multiple times or immersed in seawater, says Fan. It exceeded 1 megapascal of adhesion strength underwater - about 10 times stronger than most soft, sticky materials under the same conditions. The research "demonstrates a paradigm shift in the way we can design high-performance soft materials", says Zhao Qin at Syracuse University in New York state. He praised the team for identifying stickiness patterns in natural proteins and capturing them in the new material. The most whimsical demonstration of the hydrogel's sticky strength involved keeping that yellow rubber duck attached to the wave-soaked rock by the shore. In a more practical experiment, the hydrogel instantly sealed a leaking water pipe. This suggests it could help repair underwater structures or make flexible electronics and robotics water-resistant. The material was also biocompatible, which the researchers proved by implanting it under the skin of mice. This could make it useful for biomedical applications, such as affixing implants or working as surgical glue. The hydrogel's stickiness is remarkable, says Qin, but he notes that the material must be relatively thick to perform well. He hopes to see it tested outside ideal experimental conditions, especially in real-world situations with rough, contaminated or moving surfaces. The researchers have submitted a patent for the new material through Hokkaido University, where most of them work.

[4]

New adhesive is so sticky it can glue a rubber duck to a seaside rock

New water-resistant hydrogels, designed with the help of machine learning, are more adhesive than any comparable materials found in nature. The hydrogels were developed with the aid of an algorithm trained on the adhesives produced by natural organisms, such as geckos and mussels. The researchers that created them suggest that the new substances could have applications in areas such as surgery, marine farming and deep-sea exploration. Soft, gelatinous adhesives are difficult to design because the very properties that make adhesives strong also tend to make them brittle. Elastomeric polymer hydrogels are the best examples available, but these tend not to be very water resistant as their hydrated bonding networks are easily disrupted if water penetrates them. However, the natural world contains thousands of examples of water-resistant adhesive hydrogels in marine animals, bacteria, fungi and viruses. In the new research, soft matter expert Jian Ping Gong at Hokkaido University in Japan and colleagues elsewhere in Japan and China mined a dataset of 24,707 natural adhesive protein sequences found in a biotechnology database hosted by the US National Institutes of Health. The researchers then synthesised 180 candidates using a free-radical random copolymerisation process and tested their adhesive strength. The strongest candidate was made from amino acid chains derived from a protein produced by Escherichia bacteria. The researchers then studied features present in the most promising hydrogels and used iterative machine learning to develop a new set of candidates stronger and more stable than any found in nature. 'Our approach aims to build a systematic, data-driven, and generalisable framework, going beyond individual bio-mimic motifs to statistically capture broader sequence logic,' explains Hailong Fan, then at Hokkaido University, now at Shenzhen University in China. The team ultimately arrived at three hydrogels, one of which was around 7 times as powerful the Escherichia adhesive and could stick a rubber duck to a seaside rock, withstanding salt water and waves. Another could resist high water pressure to seal a burst pipe. The researchers showed that all three were biocompatible by implanting them in mice. 'We are customising the hydrogel for use in medical adhesives, marine repairs, and soft robotics,' says Fan. Materials scientist Ting Xu at University of California, Berkeley in the US is impressed by the materials' properties. However, she believes that the importance of machine learning in their development should not be overstated, as she doubts that the researchers would have succeeded without Gong's predictive skills. 'Jian Ping is the goddess of hydrogel,' she says. 'She has decades of experience, she just has the knowledge to be able to pick the right monomers, pick the right regions, and couple that with experimental high throughput and machine learning. I wouldn't say the modelling here is particularly exceptional, I would say it's a very good coupling of human intelligence with artificial intelligence.'

Share

Share

Copy Link

Researchers use AI and machine learning to develop water-resistant, super-adhesive hydrogels inspired by natural protein sequences, with potential applications in medicine, marine technology, and industry.

AI-Driven Design Process

Researchers have developed a groundbreaking approach to creating super-adhesive hydrogels using artificial intelligence (AI) and machine learning. The team, led by Jian Ping Gong and colleagues, drew inspiration from nature to design materials that can withstand wet environments

1

. The process began by analyzing a dataset of 24,707 naturally occurring adhesive protein sequences to guide the initial design of 180 hydrogels2

.

Source: Nature

The researchers then employed an iterative machine-learning framework to optimize adhesion performance. This data-driven approach allowed them to capture broader sequence logic beyond individual bio-mimic motifs, creating a systematic and generalizable framework

4

. The AI-assisted design process resulted in hydrogels with adhesive properties superior to those found in nature.Exceptional Underwater Performance

The newly developed hydrogels demonstrated remarkable adhesive strength in various wet environments. One of the most striking demonstrations involved gluing a rubber duck to a seaside rock, where it remained fixed despite continuous wave impacts and tidal changes for over a year

1

3

.In another test, a hydrogel was used to patch a 20-millimeter-diameter hole at the base of a 3-meter-tall water-filled pipe. The patch instantly stopped a high-pressure leak and continued to seal the hole for more than five months

2

. The adhesive strength of these hydrogels underwater exceeded 1 megapascal, approximately 10 times stronger than most soft, sticky materials under similar conditions [3](https://www.newscientist.com/article/2491328-super-sticky-hydrogel-is-10-times-stronger-than-other-glues-underwater()].Potential Applications

The super-adhesive hydrogels developed through this AI-driven process have potential applications across various fields:

-

Biomedical: The hydrogels showed biocompatibility in experiments with mice, suggesting possible uses in prosthesis coatings, wearable biosensors, and as surgical glues

2

[3](https://www.newscientist.com/article/2491328-super-sticky-hydrogel-is-10-times-stronger-than-other-glues-underwater()]. -

Marine Technology: The materials could be used in deep-sea robotics, underwater repairs, and marine farming

4

. -

Industrial Applications: The hydrogels' ability to seal leaks and adhere to irregular surfaces in wet conditions makes them promising for various industrial uses

2

.

Related Stories

Challenges and Future Directions

While the new hydrogels show great promise, some challenges remain. The material must be relatively thick to perform well, and further testing is needed in real-world conditions with rough, contaminated, or moving surfaces

3

. Additionally, the role of human expertise in conjunction with AI should not be understated, as noted by materials scientist Ting Xu4

.The researchers are currently working on customizing the hydrogel for specific applications in medical adhesives, marine repairs, and soft robotics

4

. This innovative approach to designing functional hydrogels could potentially be adapted for other types of soft materials and even automated using robotics in research laboratories2

.References

Summarized by

Navi

[1]

[4]

Related Stories

Recent Highlights

1

ByteDance's Seedance 2.0 AI video generator triggers copyright infringement battle with Hollywood

Policy and Regulation

2

Demis Hassabis predicts AGI in 5-8 years, sees new golden era transforming medicine and science

Technology

3

Nvidia and Meta forge massive chip deal as computing power demands reshape AI infrastructure

Technology