Tesla's Ambitious AI Chip Vision: Musk Targets 200 Billion Units Annually as Company Advances In-House Silicon Development

9 Sources

9 Sources

[1]

Elon Musk wants foundry partners to build '100 - 200 billion AI chips' per year -- Musk says chipmaking industry can't deliver on his goals

This is orders of magnitude more than the industry can build these days. It's no secret that Elon Musk has tremendous ambitions when it comes to artificial intelligence, but apparently, they are so tremendous that he wants to get more AI processors than the industry produces, or even can produce. As it turns out, Tesla might need '100 - 200 billion AI chips per year' and if it cannot get them from existing foundry partners, then the company will consider building its own fabs, which Musk discussed several weeks ago. Now he has elaborated on those goals further. "I have tremendous respect for TSMC and Samsung, we work with both TSMC and Samsung at Tesla and SpaceX. They are great companies and we want them to make our chip as quickly as they can and scale up to the highest possible volume that they are comfortable doing," said Elon Musk, during his conversation with Ron Baron. "But it doesn't appear to be fast enough. When I asked how long it would take from start to finish to build a new chip fab built, they said five years to get to production. Five years for me is eternity. My timelines are one year, two years. [...] I cannot even see past three years. This is not going to be fast enough. If they change their minds and say, yeah, they are going to go faster and they want to provide us with 100 billion, 200 billion AI chips a year in the time frame that we need them, that is great." Musk did not say when Tesla and SpaceX would require those 100 to 200 billion AI processors a year, but that number is pretty insane, assuming that he meant units, not dollars. To put it into context, the industry supplied 1.5 trillion semiconductor devices globally in 2023, according to the Semiconductor Industry Association. Yet, this number is a bit misleading, because the term 'chip' covers a wide variety of devices, ranging from tiny microcontrollers and sensors to memory chips and logic devices. Logic devices like Nvidia's H100 or B200/B300 AI GPUs are huge pieces of silicon that are hard to make, and thus take the longest lead and production times. Musk recently said he believed power consumption for his AI5 AI processors could drop to as low as 250W. The power rating (TDP) of a chip can often be used as a decent relative proxy for the size of a chip, and by comparison, Nvidia's B200 GPUs can consume up to 1,200W, or nearly five times more power, thus implying that the AI5 will be a much smaller chip. Regardless, there absolutely isn't enough production capacity to meet Musk's targets, even if his chips are much smaller. As one of the biggest clients of TSMC, Nvidia has supplied four million Hopper GPUs worth $100 billion (not counting China) throughout the active lifespan of the architecture, which was about two calendar years. With Blackwell, Nvidia has sold around six million GPUs, which equate to three million GPU packages, in the first four quarters of their lifespan. If Musk indeed meant 200 billion units, then he would like to get orders of magnitude more AI processors than the industry (which is largely produced by TSMC) can build in a year. Yet, if he by any chance was referring to $100 - $200 billion worth of AI processors, then TSMC and Samsung Foundry could certainly produce that volume in the coming years. However, given that Musk is not satisfied with how quickly TSMC and Samsung build fabs, it looks like he indeed thinks he needs more than these companies can supply. "We will be using TSMC fabs in Taiwan and Arizona, Samsung fabs in Korea and Texas," said Musk. "From their standpoint, they are moving like lightning. I am just saying that, nonetheless, it would be a limiting factor for us. They're going as fast as they can, but from their standpoint, it's 'pedal to the metal.' They just never had someone, a company, with our sense of urgency. It might just be that the only way to get to scale at the rate that we want to get to scale is to build up a real big fab, or be limited in output of Optimus and self-driving cars because of AI chip [supply]." Whether Tesla and SpaceX really need 100-200 billion chips per year remains unclear. Tesla sold 1.79 million vehicles in 2024, so it does not need more than two million chips for its cars. Of course, the company might need millions more AI processors for its AI training efforts, though we have reasonable doubts that it can indeed build AI clusters powered by billions of GPUs any time soon. Also, while anthropomorphic Optimus robots, also powered by Tesla's AI hardware, could be a big market, it will take years to develop.

[2]

Elon Musk says Tesla will need 100-200 billion AI chips per year, wants to build his own fabs

TL;DR: Elon Musk revealed Tesla's need for 100 to 200 billion AI chips annually, highlighting that TSMC and Samsung cannot meet this demand within his desired timeline. To avoid production delays, Tesla plans to build its own large semiconductor fab, requiring significant investment and years to scale AI chip manufacturing. Elon Musk has recently said that Tesla will need between 100 billion and 200 billion AI chips per year, and that both TSMC and Samsung can't meet that demand in the timeline he wants. Elon doubled-down on his plans for Tesla to build its own massive semiconductor fab. The comments from the SpaceX and Tesla founder were made during the Baron Investment Conference, where he said that chip giant partners like TSMC and Samsung Foundry he has "tremendous respect for" but they need 5 years to get a new chip fab plant up and running, and he added that those 5 years are "an eternity". Elon continued, explaining: "The production speed doesn't seem fast enough. When I asked them how long it would take from groundbreaking to completion of a new chip factory, they told me it would take five years to start production. I felt that five years was an endless wait for me". Elon added: "You know, from their standpoint, they're moving like lightning. I'm just saying that, nonetheless it will be a limiting factor for us... it might just be that the only way to get to scale at the rate we want to get to scale is to build a really big fab - or be limited in output of Optimus and self-driving cars behind the AI chip supply". We could see a gigantic new partnership made by Elon between Tesla and TSMC or Samsung Foundry with a massive investment, ensuring that Tesla has the hundreds of billions of AI chips it needs per year, every year, without fail. Tesla building its own semiconductor fabs makes sense, as the company is trying to have everything built in-house, but next-gen AI chips aren't easy to make. It would involve hundreds of billions of dollars of investment from Tesla, and many years to get a bunch of semiconductor fabs constructed, and then up and making hundreds of billions of AI chips every year.

[3]

Elon Musk Talks Up Tesla's AI Chip Capabilities. Its Stock Is Surging.

Elon Musk wants investors to know Tesla is an AI chip company, too. "Most people don't know that Tesla has had an advanced AI chip and board engineering team for many years," the CEO posted on his social media site X Sunday, continuing that Tesla (TSLA) "has already designed and deployed several million AI chips" in its vehicles and data centers. Tesla's stock surged over 6% in recent trading following the post, making it one of the biggest gainers in the S&P 500. Rising expectations of a Federal Reserve rate cut next month -- which could also benefit the electric vehicle maker by stimulating demand for big-ticket purchases -- likely also helped boost sentiment for the stock Monday, along with broader markets. "These chips are what enable Tesla to be the leader in real-world AI," Musk said in his post over the weekend. The company is close to upgrading the current version of its chip, called AI4, to AI5, he said, and is starting work on a newer model AI6. Musk said Tesla now plans to get a new AI chip design into production every 12 months, and that it expects "to build chips at higher volumes ultimately than all other AI chips combined," furthering Tesla's self-driving and robotics goals. Musk also used his post to solicit applications from engineers who want to work on Tesla's AI chip program. With Monday's gains, shares of Tesla are back in positive territory for the year. Still, they've lost more than 10% from their highs at the start of the month, having taken a big hit during the broader pullback in tech stocks in recent weeks amid worries about an AI bubble.

[4]

Elon Musk's Tesla to Build More AI Chips Than All Other Companies Combined

Elon Musk is also hiring engineers for the company's AI chip division Elon Musk, on Sunday, revealed that Tesla has started the tape out process of the company's new AI5 chipset. It is the successor to the AI4 chip, which is implemented in the latest Tesla cars. Additionally, the electric vehicles (EV) manufacturer has also started working on the next generation of artificial intelligence (AI) chipset, AI6, Musk confirmed. The multipreneur also highlighted that the Texas-based company is now planning to scale its chip deployment to rival all the AI chipmakers globally. Tesla to Ramp Up AI Chipset Development Efforts In a post on X (formerly known as Twitter), the Tesla CEO highlighted that the company is close to taping out the AI5 chipset, which will replace AI4, the chips powering the current generation of Tesla cars. Taping out is one of the final steps in chipset design, where the finalised chip design is sent for fabrication at a foundry, and is then manufactured. On the side, Tesla has also started the design process for the next generation of the AI6 chip. Posting about the current chip development of Tesla, Musk highlighted that many were still unaware that the company had an AI chip division and dedicated engineering team for several years, and has designed and deployed millions of AI chips for its EVs and data centres. The company's full self-driving (FSD) system is also powered by these processors. Musk also shared details about the company's vision for the future, adding, "Our goal is to bring a new AI chip design to volume production every 12 months. We expect to build chips at higher volumes ultimately than all other AI chips combined." Tesla CEO highlighted that these chipsets are also being used in the company's Optimus humanoid robots, and play a crucial role in providing advanced medical care to people. According to a Bloomberg report, Samsung secured a $16.5 billion deal with Tesla, giving them the rights to produce AI chipsets. At the time, Musk reportedly said that a new Samsung foundry built in Texas will be entirely dedicated to fabricate the AI6 processor. Tesla is also hiring engineers with experience in chip designing. Musk highlighted in the post that individuals interested in working for the company can apply for open positions. "We are particularly interested in applying cutting edge AI to chip design," he added.

[5]

Elon Musk pitches Tesla's in-house AI chip ambitions, seeks talent for next-generation designs - The Economic Times

Tesla has been developing its own advanced AI chips for years, with Elon Musk revealing that millions of AI4 chips are already deployed. The company is on track to release AI5 soon and aims for a new chip design every 12 months, with ambitious plans to outproduce other AI chip manufacturers.Elon Musk has said Tesla has been building advanced AI chips for several years, revealing details about the electric carmaker's in-house silicon roadmap as it looks to scale its autonomous driving and humanoid robotics efforts. In a post on X, Musk said Tesla's internal chip and board engineering team has already designed and deployed "several million AI chips" across its vehicles and data centres, hardware that he claimed underpins the company's efforts around real-world AI training. According to Musk, the current generation of chips used in Tesla cars is AI4, while AI5 is close to tape-out and early work has begun on AI6. Tesla's ambition, he said, is to bring a new AI chip design to volume production every 12 months, adding that the company expects to ultimately manufacture chips "at higher volumes than all other AI chips combined." "These chips will profoundly change the world in positive ways, saving millions of lives due to safer driving and providing advanced medical care to all people via Optimus," Musk wrote. Tesla has also opened a direct hiring channel for AI silicon engineers, asking candidates to send evidence of their "exceptional ability" to a dedicated email address. Musk said the company is particularly keen on talent that can apply cutting-edge AI techniques to chip design, an area increasingly seen as a competitive frontier among global tech firms. The announcement comes as automakers and Big Tech companies step up efforts to build custom silicon to power autonomous driving and robotics, competing with GPU-heavy architectures dominated by Nvidia.

[6]

Tesla AI Chief Ashok Elluswamy Touts Elon Musk's Efforts To Build More AI Chips: 'Heavily Co-Designed With...' - Tesla (NASDAQ:TSLA)

Tesla Inc. (NASDAQ:TSLA) AI lead Ashok Elluswamy has weighed in on the automaker's chip-building efforts amid an artificial intelligence and self-driving push. Chips Co-Designed With Tesla AI Software Teams Elluswamy, quoting a post by the CEO on the social media platform X, said that the chips that Tesla is building are "heavily co-designed with the Tesla AI software teams." He also added that the chips were designed to achieve better margins on "perf per Watt and perf per dollar" than other AI hardware systems. Perf per Watt, or Performance per Watt, is a metric used to calculate a computer hardware's energy efficiency figures it delivers for the amount of power it consumes. Perf per dollar, or Performance per Dollar, measures the computational power a system delivers for what it costs. He also outlined that Tesla's AI4 Chip "can process and understand a million pixels of streaming video" within approximately 1 millisecond, adding that the feat was possible because Tesla's "software AND the hardware are designed together." Elon Musk's Bold AI Chip Prediction, FSD's Final Puzzle Piece The comments follow Musk's claim that Tesla would produce more AI Chipsets than any other chipmaker. "We expect to build chips at higher volumes ultimately than all other AI chips combined," Musk said in a recent post, highlighting the automaker's AI push. Meanwhile, Musk also hinted at the possibility of Tesla's Full Self-Driving technology finally achieving unsupervised autonomous driving as he teased the FSD v14.3 update as the last piece of the puzzle for the technology. Tesla's Robotaxi Push What could be another boost for the company's autonomous driving efforts is the Tesla Robotaxi clearing the self-certification process in the state of Nevada, which could pave the way for commercial Robotaxi operations within the state. Musk had earlier said that the company would expand Robotaxis to Arizona, Nevada and Florida by the end of the year and predicted that Tesla Robotaxis in Austin would go driverless by the end of 2025. Tesla scores well on Momentum and Quality metrics, while offering satisfactory Growth, but poor Value. Tesla also has a favourable price trend in the Medium and Long term. For more such insights, sign up for Benzinga Edge Stock Rankings today! Price Action: TSLA, despite sliding 1.05 to $391.01 at market close on Friday, surged 0.70% to $393.83 during after-hours trading, according to Benzinga Pro data. Check out more of Benzinga's Future Of Mobility coverage by following this link. Read Next: Tesla Eyes February 2026 For Full Self-Driving Approval In Europe Image via Shutterstock TSLATesla Inc$393.83-%OverviewMarket News and Data brought to you by Benzinga APIs

[7]

Why Tesla Stock Jumped 6.8% Today | The Motley Fool

On Sunday, Musk took to X to talk up his company's artificial intelligence (AI) chip business, saying, "Most people don't know that Tesla has had an advanced AI chip and board engineering team for many years." According to Musk, the team has already "designed and deployed several million AI chips" in Tesla vehicles and data centers, and that the chips would "profoundly change the world in positive ways." He added that the company would match AI chip giant Nvidia's update cadence, bringing a new chip to "volume production" every 12 months in order to fulfill the company's self-driving and humanoid robot ambitions.

[8]

Tesla rallies after Elon Musk highlights its AI chip design upside (TSLA:NASDAQ)

Tesla (TSLA) shot up on Monday after Elon Musk highlighted over the weekend that the company is in the business of AI chip design. "Most people don't know that Tesla has had an advanced AI chip and board engineering Tesla's advanced AI chips and rapid development cycle are increasing its lead in autonomy and AI, making competition from legacy automakers harder. AI5 and AI6 chips are expected to enhance self-driving capabilities, robotics, and data centers with more computational power and unified training/inference. Analysts, like those at Melius, consider Tesla a 'must own,' citing its widening lead in AI chips, vertical integration, and software design.

[9]

Elon Musk Says Tesla Will Build More AI Chips Than Everyone Else Combined, Unveils Major Hiring Drive: 'I'm Not Kidding' - Samsung Electronics Co (OTC:SSNLF), Tesla (NASDAQ:TSLA)

Elon Musk said Tesla Inc. (NASDAQ:TSLA) plans to build AI chips at volumes surpassing every competitor combined as the company launches a sweeping recruitment push for top-tier chip designers. Tesla's Expanding In-House AI Chip Program Over the weekend, Musk said on X, formerly Twitter, that Tesla had an advanced in-house AI chip and board engineering team "for many years." He continued saying that the group has already designed and deployed "several million" chips across its vehicles and data centers. These chips underpin Tesla's lead in real-world AI and autonomous driving. Musk noted that Tesla is currently shipping the fourth version of its AI chip, known as AI4, while preparing to finalize AI5 and beginning early work on AI6. The company's long-term target, he said, is to bring a new chip design into volume production every 12 months. He added that Tesla ultimately expects to produce more AI chips than the entire rest of the industry, writing, "We expect to build chips at higher volumes ultimately than all other AI chips combined. Read that sentence again, as I'm not kidding." See Also: Cybertruck 'The Best Robot Out There,' Says Jack Dorsey As Elon Musk Takes Note Musk's Aggressive Recruitment Push Begins Musk also announced a major hiring drive, calling for candidates with "exceptional ability" in AI and semiconductor engineering to email [email protected] with three bullet points detailing proof of their talent. "We are particularly interested in applying cutting-edge AI to chip design," Musk said, adding that the next generation of Tesla's chips will "profoundly change the world" through safer driving and future products like the Optimus humanoid robot. Tesla Faces AI5 Chip Delay As Musk Pushes TSMC, Samsung To Speed Up Earlier this month, Musk said Tesla's AI5 chips won't be available in meaningful volumes until mid-2027. The delay is notable given his push to shorten development cycles and his ongoing pressure on manufacturing partners like Taiwan Semiconductor Manufacturing Co. (NYSE:TSM) and Samsung Electronics Co. (OTC:SSNLF) to speed up production, arguing that a five-year timeline is too slow for Tesla's pace of innovation. In October, Musk confirmed that Samsung would help produce the AI5 chip alongside TSMC -- a move aimed at diversifying suppliers and increasing capacity. Although the AI5 chip is expected to significantly boost the intelligence of Tesla vehicles, the setback means the company's shift to the new hardware will take longer than planned. Musk added that Tesla expects to have samples -- and possibly limited quantities -- of the AI6 chip in 2026, but large-scale production won't begin until 2027. Benzinga's Edge Stock Rankings show that although Tesla's short-term price trend has slowed, the company continues to demonstrate strong medium and long-term growth potential. Click here to see how it stacks up against its peers. Read Next: David Tepper's Hedge Funds Bets On AMD, Nvidia In Q3, Takes Profits On Intel Photo Courtesy: Mijansk786 on Shutterstock.com Disclaimer: This content was partially produced with the help of AI tools and was reviewed and published by Benzinga editors. SSNLFSamsung Electronics Co Ltd$65.21-%OverviewTSLATesla Inc$393.830.70%TSMTaiwan Semiconductor Manufacturing Co Ltd$275.250.07%Market News and Data brought to you by Benzinga APIs

Share

Share

Copy Link

Elon Musk reveals Tesla's massive AI chip ambitions, seeking 100-200 billion chips annually while advancing its in-house AI5 and AI6 processors. The company may build its own fabs due to foundry timeline constraints.

Tesla's Unprecedented AI Chip Ambitions

Elon Musk has revealed Tesla's staggering ambition to secure between 100 and 200 billion AI chips annually, a demand that far exceeds current global semiconductor production capacity

1

. Speaking at the Baron Investment Conference, Musk expressed frustration with the timeline constraints of major foundry partners like TSMC and Samsung, stating that their five-year fab construction timeline represents "an eternity" for his accelerated development goals2

.

Source: TweakTown

To put this demand in perspective, the global semiconductor industry supplied 1.5 trillion devices in 2023, but this figure includes all types of chips from simple sensors to complex processors

1

. Musk's requirements represent orders of magnitude more than what current AI chip production can deliver, particularly for sophisticated processors needed for autonomous driving and robotics applications.In-House Silicon Development Accelerates

Tesla has been quietly developing advanced AI chips for several years through its dedicated chip and board engineering team

3

. The company has already designed and deployed "several million AI chips" across its vehicles and data centers, with the current AI4 generation powering Tesla's latest cars and full self-driving systems4

.Musk announced that Tesla is close to completing the tape-out process for its next-generation AI5 chipset, while simultaneously beginning development of the AI6 processor

5

. The company aims to bring a new AI chip design to volume production every 12 months, with the ambitious goal of ultimately manufacturing chips "at higher volumes than all other AI chips combined."

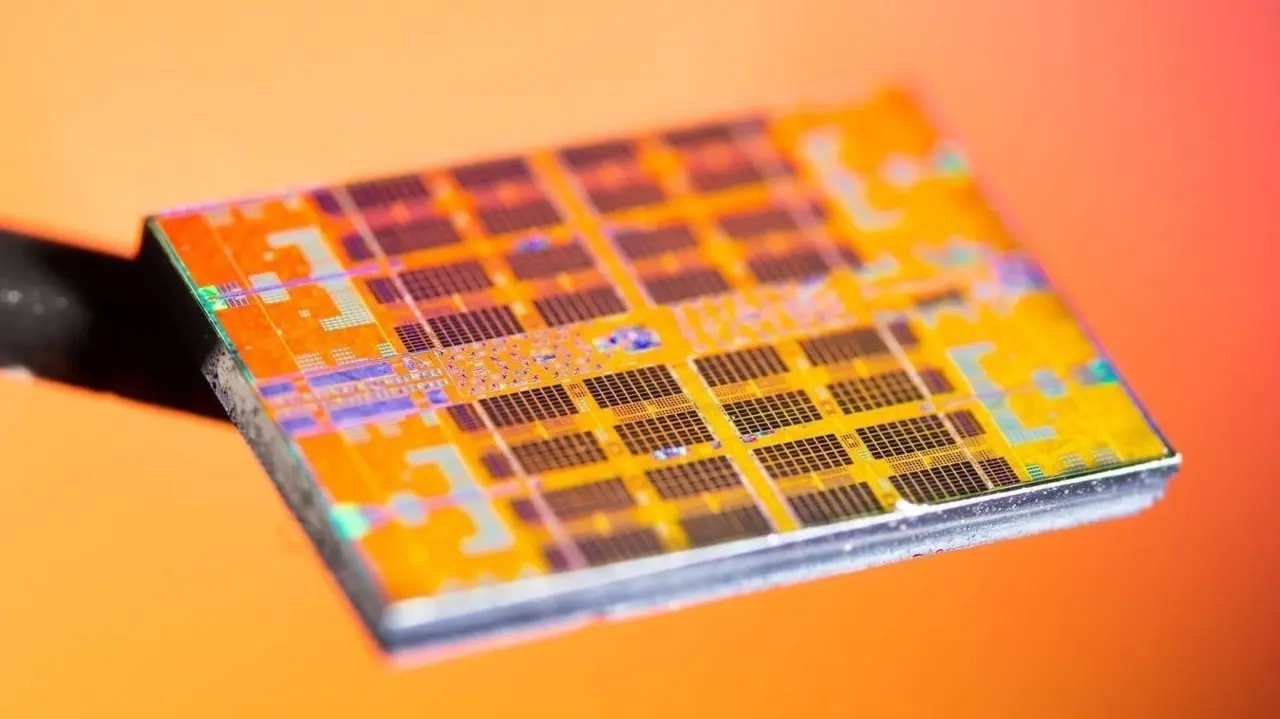

Source: Benzinga

Market Response and Strategic Implications

Tesla's stock surged over 6% following Musk's revelations about the company's AI chip capabilities, making it one of the biggest gainers in the S&P 500

3

. The announcement highlighted Tesla's position as both an automotive manufacturer and a significant player in AI hardware development, with applications extending beyond vehicles to include the company's Optimus humanoid robots.

Source: Gadgets 360

Musk emphasized that these chips are crucial for Tesla's real-world AI leadership and will "profoundly change the world in positive ways, saving millions of lives due to safer driving and providing advanced medical care to all people via Optimus"

5

. The company has also opened direct hiring channels for AI silicon engineers, seeking candidates with "exceptional ability" in applying cutting-edge AI techniques to chip design.Related Stories

Foundry Partnerships and Future Plans

Despite his urgency concerns, Musk maintains respect for existing foundry partners, stating that Tesla will continue using TSMC facilities in Taiwan and Arizona, along with Samsung fabs in Korea and Texas

1

. Samsung has reportedly secured a $16.5 billion deal with Tesla, with a new Texas foundry potentially dedicated entirely to fabricating the AI6 processor4

.However, if existing partners cannot meet Tesla's aggressive timeline and volume requirements, the company is prepared to invest hundreds of billions of dollars in building its own semiconductor fabrication facilities

2

. This vertical integration strategy aligns with Tesla's broader approach of bringing critical components in-house to maintain control over supply chains and development timelines.References

Summarized by

Navi

[1]

[2]

Related Stories

Tesla Unveils AI5 Chip: A Game-Changer in Performance and Manufacturing Strategy

23 Oct 2025•Technology

Elon Musk Announces Ambitious Plan to Outproduce All AI Chip Makers Combined with Tesla's Custom Silicon

25 Nov 2025•Technology

Tesla's Stock Soars Amid Autonomous Driving Advancements and Regulatory Shifts

26 Apr 2025•Business and Economy

Recent Highlights

1

Google Gemini 3.1 Pro doubles reasoning score, beats rivals in key AI benchmarks

Technology

2

Meta strikes up to $100 billion AI chips deal with AMD, could acquire 10% stake in chipmaker

Technology

3

Pentagon threatens Anthropic with supply chain risk label over AI safeguards for military use

Policy and Regulation