Dassault NVIDIA Partnership Merges Virtual Twin Tech With Industrial AI to Transform Engineering

3 Sources

3 Sources

[1]

Everything Will Be Represented in a Virtual Twin, Jensen Huang Says at 3DEXPERIENCE World

NVIDIA founder and CEO Jensen Huang and Dassault Systèmes CEO Pascal Daloz announced a partnership to build a shared industrial AI architecture, merging virtual twins with physics-based AI to redefine the future of design, engineering and manufacturing. At 3DEXPERIENCE World in Houston, NVIDIA founder and CEO Jensen Huang and Dassault Systèmes CEO Pascal Daloz laid out a blueprint for industrial AI rooted in physics-based "world models" -- systems designed to simulate products, factories and even biological systems before they're built. "Artificial intelligence will be infrastructure," like water, electricity, and the internet Huang told the crowd, playfully referring to the engineering-heavy audience as "Solid Workers," a nod to Dassault Systèmes' SolidWorks platform. The announcement continues a collaboration spanning more than a quarter century between NVIDIA and Dassault Systèmes. "This is the largest collaboration our two companies have ever had in over a quarter century," Huang said. "We're going to fuse these technologies so engineers can work at a scale that's 100 times, 1,000 times -- and eventually a million times greater than before." The new partnership brings NVIDIA accelerated computing and AI libraries together with Dassault Systèmes' Virtual Twin platforms to move more engineering work into real-time digital workflows, powered by AI companions that help teams explore, validate, prototype and iterate faster. Huang framed the shift as a reinvention of the computing stack: moving from hand-specified, structured digital designs to systems that can generate, simulate and optimize in software -- at industrial scale. From Digital Models to Industry World Models Virtual twins are not applications, "they are knowledge factories," Daloz said. The partnership aims to establish industry world models -- science-validated AI systems grounded in physics that can serve as mission-critical platforms across biology, materials science, engineering and manufacturing. In Daloz's framing, the value moves upstream: virtual twins become the place where knowledge is created, tested, and trusted -- before anything is built in the physical world. Dassault Systèmes, whose 3DEXPERIENCE platform serves more than 45 million users and 400,000 customers globally, has long been a leader in virtual twin technology -- digital replicas that let engineers simulate products and processes before building them physically. The collaboration brings together accelerated computing, AI and digital twin technologies so engineers can design not only geometry, but behavior -- and explore radically larger design spaces earlier in development. Together, the companies outlined how this shared architecture will show up across science, engineering and manufacturing workflows: * Advancing Biology and Materials Research: The NVIDIA BioNeMo platform and BIOVIA science-validated world models accelerate the discovery of new molecules and next-generation materials. * AI-Driven Design and Engineering: SIMULIA AI-based Virtual Twin Physics Behavior leveraging NVIDIA CUDA-X libraries and AI physics libraries empowers designers and engineers to accurately and instantly predict outcomes. * Virtual Twins for Every Factory: NVIDIA Omniverse physical AI libraries integrated into the DELMIA Virtual Twin enable autonomous, software-defined production systems. * Virtual Companions Supercharge Dassault Systèmes' Users: The 3DEXPERIENCE agentic platform, combining NVIDIA AI technologies and NVIDIA Nemotron open models with Dassault Systèmes' Industry World Models, powers Virtual Companions to tap into deep industrial context, delivering trusted, actionable intelligence. Huang said that in domains like biology and materials, the frontier is learning the underlying "language" of complex systems and then generating new options that can be evaluated and validated in simulation. Designing and Operating the Factory in Software A central theme of the discussion was how factories themselves are changing -- from static physical assets to living systems that are designed, simulated and operated as virtual twins. As part of the partnership, Dassault Systèmes is deploying NVIDIA-powered AI factories on three continents through its OUTSCALE sovereign cloud, enabling customers to run AI workloads while maintaining data residency and security requirements. Both executives emphasized that the goal isn't to replace engineers -- it's to amplify them. As AI agent companions take on more exploratory and repetitive tasks, designers and engineers gain leverage and creativity, not redundancy. AI Companions That Expand Human Creativity Every designer will have a "team of companions," Huang said -- a shift he described as fundamentally positive for engineers, software platforms and the broader ecosystem built on them. For the tens of millions of engineers who use Dassault Systèmes tools to design everything from aircraft to consumer packaged goods, the shift isn't about replacing human creativity -- it's about expanding it. "Success is not about automation," Daloz said. "[Engineers] don't want to automate the past -- they want to invent the future." Looking ahead, Daloz framed the partnership as about more than performance gains - it's an effort to open new possibilities, help companies eliminate bad choices before they become expensive mistakes, and create entirely new categories of products. "Virtual twins and the 3D Universes are not applications," Daloz said. "They are knowledge factories." The fireside conversation between Huang and Daloz was broadcast live from 3DEXPERIENCE World.

[2]

Dassault Systèmes and NVIDIA Unite to Supercharge Virtual Twins with AI

* Shared industrial AI architecture combines Virtual Twins and AI infrastructure deployable at scale. * Science-validated world models position industrial AI as a mission-critical system of record, not a point solution. * Platform accelerated by NVIDIA, grounded in science by Dassault Systèmes, expands long-term value creation across biology, materials science, engineering and manufacturing through a new way of working: skilled virtual companions. Dassault Systèmes and NVIDIA today announced a long-term strategic partnership to establish a shared industrial architecture for mission-critical artificial intelligence across industries. Combining Dassault Systèmes' Virtual Twin technologies with NVIDIA AI infrastructure, open models and accelerated software libraries will establish science-validated industry World Models, and new ways of working through skilled virtual companions on the agentic 3DEXPERIENCE platform, that empower professionals with new expertise. "We are entering an era where artificial intelligence does not just predict or generate, but understands the real world. When AI is grounded in science, physics and validated industrial knowledge, it becomes a force multiplier for human ingenuity," said Pascal Daloz, CEO of Dassault Systèmes. "Together with NVIDIA, we are building industry World Models that unite Virtual Twins and accelerated computing to help industry design, simulate and operate complex systems in biology, materials science, engineering and manufacturing with confidence. This partnership establishes a new foundation for industrial AI, one that is trustworthy by design and capable of scaling innovation across the generative economy." "Physical AI is the next frontier of artificial intelligence, grounded in the laws of the physical world," said Jensen Huang, founder and CEO of NVIDIA. "Together with Dassault Systèmes, we're uniting decades of industrial leadership with NVIDIA's AI and Omniverse platforms to transform how millions of researchers, designers and engineers build the world's largest industries." Dassault Systèmes and NVIDIA Partner to Accelerate Every Industry Dassault Systèmes, with its OUTSCALE brand, is deploying AI factories as part of its sustainable and sovereign cloud strategy. OUTSCALE AI factories will harness the latest NVIDIA AI infrastructure on three continents, bringing additional capabilities to operate AI models in the 3DEXPERIENCE platform, while guaranteeing data privacy, intellectual property protection and sovereignty of Dassault Systèmes' customers. NVIDIA is adopting Dassault Systèmes model-based systems engineering (MBSE) to design AI factories, starting with the NVIDIA Rubin platform and integrating into the NVIDIA Omniverse™ DSX Blueprint for large-scale AI factory deployment. This infrastructure will power Dassault Systèmes' industrial Virtual Twins using NVIDIA open models and libraries, unlocking new opportunities across biology, materials science, engineering and manufacturing: * Advancing Biology and Materials Research: The NVIDIA BioNeMo™platform combined with BIOVIA science-validated world models will accelerate the discovery of new molecules and next-generation materials. * AI-Driven Design and Engineering: SIMULIA AI-based Virtual Twin Physics Behavior leveraging NVIDIA CUDA-X™ libraries and AI physics libraries empowers designers and engineers to accurately and instantly predict outcomes. * Virtual Twins for Every Factory: NVIDIA Omniverse physical AI libraries integrated into the DELMIA Virtual Twin of global production systems enable autonomous, software-defined production systems. * Virtual Companions Supercharge Dassault Systèmes' Users: The 3DEXPERIENCE agentic platform, combining NVIDIA AI technologies and NVIDIA Nemotron™ open models with Dassault Systèmes' Industry World Models, powers Virtual Companions to tap into deep industrial context, delivering trusted, actionable intelligence with industrial-scale efficiency. The partnership elevates the existing collaboration between Dassault Systèmes and NVIDIA to a shared long-term vision for how industrial AI will be built, validated and deployed at scale, through a unique combination of Dassault Systèmes' Virtual Twin Factories and NVIDIA's AI technologies for all industries. Global Leaders Build the Future of Industry With Dassault Systèmes and NVIDIA "Bel Group is building a sustainable food future through responsible formulation and packaging. Through the NVIDIA-Dassault Systèmes collaboration, we gain the computational power to model and optimize our products at scale-accelerating innovation while delivering on our sustainability commitments," said Cécile Béliot, CEO of Bel Group. "To address the growing complexity of modern manufacturing, the industry must move toward fully autonomous and digitally validated production systems," said Motohiro Yamanishi, President of Industrial Automation at OMRON. "By combining NVIDIA Physical AI frameworks with Dassault Systèmes' Virtual Twin Factory and OMRON's automation technologies, manufacturers can move from design to deployment with greater confidence and speed." "Lucid's award-winning engineering and technology continues to set new standards in the automotive industry, and Dassault Systèmes remains a key partner, enabling us to stay at the forefront of vehicle and powertrain engineering," said Vivek Attaluri, Vice President of Vehicle Engineering at Lucid. "Agility, speed of innovation and rapid iteration are at the core of our work flows, and our exploration of Virtual Twin AI-based physics, powered by NVIDIA's open-source physics informed AI models, has the potential to help our teams move from concept to production faster than ever before, without sacrificing predictive accuracy. We look forward to continued collaboration and leveraging these new tools to support Lucid's future innovations." "NIAR empowers the next generation of aircraft. From asset digitization through design and manufacturing creation and validation, Virtual Twin technology introduces unparalleled capabilities and efficiency. Dassault Systèmes' Virtual Companions for engineering, leveraging the 3DEXPERIENCE agentic platform using NVIDIA Nemotron open models and Dassault Systèmes Industry World Models, accelerate the by-design compliant synthesis of aircraft Virtual Twins. Using the platform to align the Virtual Twin to the means of compliance, reduces certification efforts while preserving sovereignty of the information," said Shawn Ehrstein, Director, Emerging Technologies and CAD/CAM, National Institute for Aviation Research, Wichita State University. The partnership was announced today at 3DEXPERIENCE World, Dassault Systèmes' annual event dedicated to the design and engineering communities. Daloz and Huang were on stage to discuss the future of industry powered by AI on Tuesday, Feb. 3, at 9 a.m. CT. A replay of the conversation will be available on YouTube. Dassault Systèmes is a catalyst for human progress. Since 1981, the company has pioneered virtual worlds to improve real life for consumers, patients and citizens. With Dassault Systèmes' 3DEXPERIENCE platform, 370,000 customers of all sizes, in all industries, can collaborate, imagine and create sustainable innovations that drive meaningful impact.

[3]

Dassault Systemes and NVIDIA Partner to Build Industrial Ai Platform Powering Virtual Twins

Dassault Systemes and NVIDIA announced a long-term strategic partnership to establish a shared industrial architecture for mission-critical artificial intelligence across industries. Combining Dassault Systèmes? Virtual Twin technologies with NVIDIA AI infrastructure, open models and accelerated software libraries will establish science-validated industry World Models, and new ways of working through skilled virtual companions on the agentic 3DEXPERIENCE platform, that empower professionals with new expertise. Dassault Systèmes, with its OUTSCALE brand, is deploying AI factories as part of its sustainable and sovereign cloud strategy. OUTSCALE AI factories will harness the latest NVIDIA AI infrastructure on three continents, bringing additional capabilities to operate AI models in the 3DEXPERIENCE platform, while guaranteeing data privacy, intellectual property protection and sovereignty of Dassault Systèmes? customers. NVIDIA is adopting Dassault Systèmes model-based systems engineering (MBSE) to design AI factories, starting with the NVIDIA Rubin platform and integrating into the NVIDIA Omniverse DSX Blueprint for large-scale AI factory deployment. This infrastructure will power Dassault Systèmes? industrial Virtual Twins using NVIDIA open models and libraries, unlocking new opportunities across biology, materials science, engineering and manufacturing: Advancing Biology and Materials Research: The NVIDIA BioNeMoplatform combined with BIOVIA science-validated world models will accelerate the discovery of new molecules and next-generation materials. AI-Driven Design and Engineering: SIMULIA AI-based Virtual Twin Physics Behavior leveraging NVIDIA CUDA-X libraries and AI physics libraries empowers designers and engineers to accurately and instantly predict outcomes. Virtual Twins for Every Factory: NVIDIA Omniversephysical AI libraries integrated into the DELMIA Virtual Twin of global production systems enable autonomous, software-defined production systems. Virtual Companions Supercharge Dassault Systèmes? Users: The 3DEXPERIENCE agentic platform, combining NVIDIA AI technologies and NVIDIA Nemotron open models with Dassault Systèmes? Industry World Models, powers Virtual Companions to tap into deep industrial context, delivering trusted, actionable intelligence with industrial-scale efficiency. The partnership elevates the existing collaboration between Dassault Systèmes and NVIDIA to a shared long-term vision for how industrial AI will be built, validated and deployed at scale, through a unique combination of Dassault Systèmes? Virtual Twin Factories and NVIDIA?s AI technologies for all industries.

Share

Share

Copy Link

Dassault Systèmes and NVIDIA announced a long-term strategic partnership to build a shared industrial AI architecture that combines Virtual Twin technologies with AI infrastructure. The collaboration will establish science-validated industry World Models and deploy skilled virtual companions across biology, materials science, engineering and manufacturing, fundamentally changing how millions of professionals design and simulate complex systems.

Dassault NVIDIA Partnership Establishes New Foundation for Industrial AI

Dassault Systèmes and NVIDIA have announced a long-term strategic partnership that marks their largest collaboration in over a quarter century. Speaking at

3DEXPERIENCE World

in Houston,Jensen Huang

, NVIDIA founder and CEO, andPascal Daloz

, CEO of Dassault Systèmes, unveiled plans to build a shared industrial AI architecture that merges Virtual Twin technologies with AI infrastructure to redefine design, engineering and manufacturing workflows1

.

Source: NVIDIA

The partnership combines Dassault Systèmes' Virtual Twin platforms, which serve more than 45 million users and 400,000 customers globally, with NVIDIA's accelerated computing, open models and accelerated software libraries

1

. Huang told the engineering-focused audience that artificial intelligence will become infrastructure like water, electricity and the internet, enabling engineers to work at scales 100 times, 1,000 times and eventually a million times greater than before1

.Science-Validated Industry World Models Ground AI in Physics

At the core of this collaboration are industry World Models—science-validated AI systems grounded in physics that can serve as mission-critical platforms across multiple domains

2

. Daloz emphasized that virtual twins are not merely applications but "knowledge factories" where information is created, tested and trusted before anything is built in the physical world1

."We are entering an era where artificial intelligence does not just predict or generate, but understands the real world," Daloz stated. "When AI is grounded in science, physics and validated industrial knowledge, it becomes a force multiplier for human ingenuity"

2

. The partnership aims to move engineering work into real-time digital workflows where teams can explore, validate, prototype and iterate faster with AI companions that understand deep industrial context1

.AI Infrastructure Deployment Across Three Continents

Dassault Systèmes, through its

OUTSCALE

brand, is deploying AI factories as part of its sustainable and sovereign cloud strategy. These OUTSCALE AI factories will harness the latest NVIDIA AI infrastructure on three continents, bringing capabilities to operate AI models in the3DEXPERIENCE platform

while guaranteeing data privacy, intellectual property protection and sovereignty for customers2

3

.In a notable technical exchange, NVIDIA is adopting Dassault Systèmes model-based systems engineering (MBSE) to design AI factories, starting with the NVIDIA Rubin platform and integrating into the

NVIDIA Omniverse

DSX Blueprint for large-scale AI factory deployment3

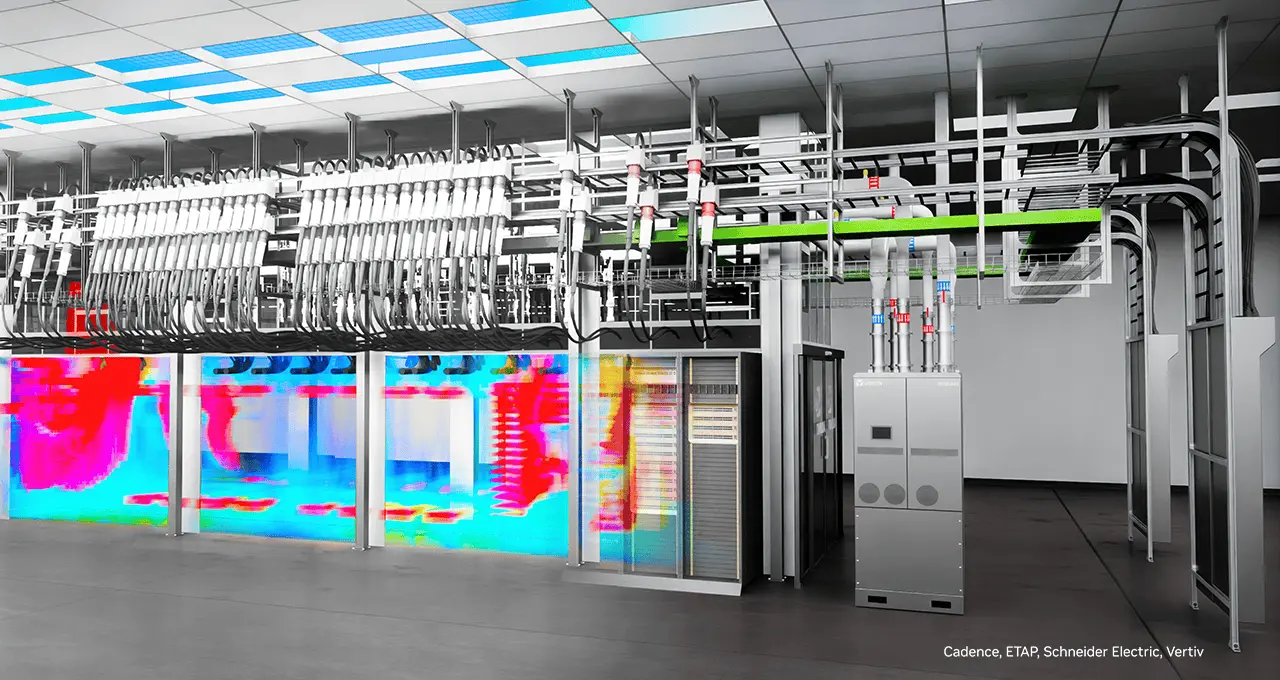

.Four Pillars of AI-Driven Design and Engineering

The shared architecture will manifest across four key domains. For advancing biology and materials research, the NVIDIA

BioNeMo

platform combined withBIOVIA

science-validated world models will accelerate the discovery of new molecules and next-generation materials2

. In AI-driven design and engineering, SIMULIA AI-based Virtual Twin Physics Behavior leveraging NVIDIACUDA-X

libraries and AI physics libraries empowers designers and engineers to accurately and instantly predict outcomes2

.For manufacturing, NVIDIA Omniverse physical AI libraries integrated into the

DELMIA Virtual Twin

of global production systems enable autonomous, software-defined production systems2

. A central theme emphasized by both executives is how factories themselves are transforming from static physical assets to living systems designed, simulated and operated as virtual twins1

.

Source: CXOToday

Related Stories

Skilled Virtual Companions Amplify Human Expertise

The 3DEXPERIENCE agentic platform, combining NVIDIA AI technologies and

NVIDIA Nemotron

open models with Dassault Systèmes' industry World Models, powers skilled virtual companions that tap into deep industrial context, delivering trusted, actionable intelligence2

. Huang described a future where every designer will have a "team of companions"—a shift he characterized as fundamentally positive for engineers and the broader ecosystem1

.Both executives stressed that the goal isn't to replace engineers but to amplify them. As AI agent companions take on more exploratory and repetitive tasks, designers and engineers gain leverage and creativity

1

. Huang framed the shift as a reinvention of the computing stack, moving from hand-specified, structured digital designs to systems that can generate, simulate and optimize in software at industrial scale1

.Industry Leaders Signal Adoption Across Materials Science and Manufacturing

Global companies are already positioning themselves to leverage this collaboration. Cécile Béliot, CEO of Bel Group, stated that through the NVIDIA-Dassault Systèmes collaboration, the company gains computational power to model and optimize products at scale, accelerating innovation while delivering on sustainability commitments

2

. Motohiro Yamanishi, President of Industrial Automation at OMRON, noted that addressing the growing complexity of modern manufacturing requires moving toward fully autonomous and digitally validated production systems2

.For the tens of millions of engineers who use Dassault Systèmes tools to design everything from aircraft to consumer packaged goods, this partnership signals a fundamental shift in how simulation, materials science and manufacturing workflows will operate. The collaboration positions Industrial AI as a mission-critical system of record rather than a point solution, with implications extending across biology, materials science, engineering and manufacturing sectors

2

.References

Summarized by

Navi

Related Stories

NVIDIA Expands Omniverse Blueprint for AI Factory Digital Twins, Accelerating Industrial AI Development

19 May 2025•Technology

NVIDIA Unveils Omniverse Blueprint for Real-Time Physics Digital Twins

19 Nov 2024•Technology

NVIDIA Expands Omniverse Platform to Revolutionize AI Factory Design and Industrial Robotics

19 Mar 2025•Technology

Recent Highlights

1

Pentagon threatens Anthropic with Defense Production Act over AI military use restrictions

Policy and Regulation

2

Google Gemini 3.1 Pro doubles reasoning score, beats rivals in key AI benchmarks

Technology

3

Anthropic accuses Chinese AI labs of stealing Claude through 24,000 fake accounts

Policy and Regulation