Nvidia and TSMC Celebrate First US-Made Blackwell Wafer, Marking Milestone in American Chip Manufacturing

15 Sources

15 Sources

[1]

Nvidia and TSMC produce the first Blackwell wafer made in the U.S. -- chips still need to be shipped back to Taiwan to complete the final product

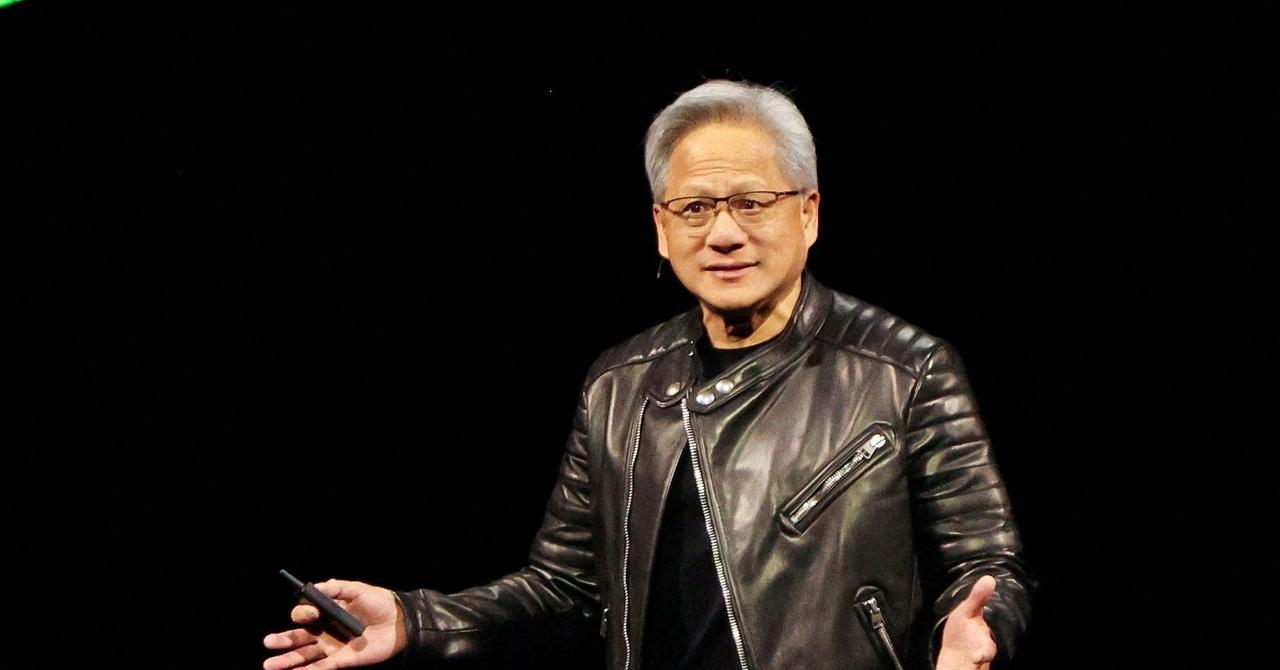

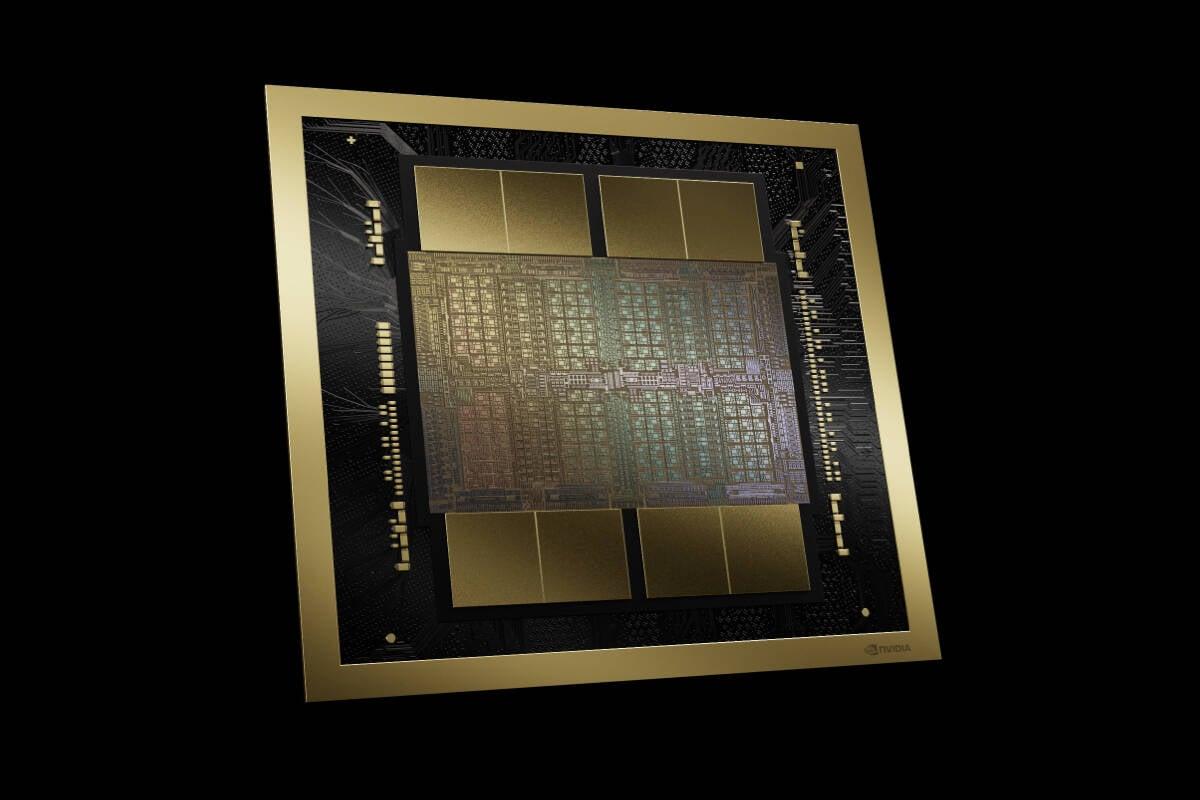

Nvidia and TSMC on Friday announced they had reached a significant milestone with the manufacturing of the first production Blackwell wafer at Fab 21 near Phoenix, Arizona. The achievement of making one of the most complex chips in history in the U.S. has strategic, symbolic, and political importance for both companies, but there is a major catch. "This is a historic moment for several reasons," said Jensen Huang, chief executive of Nvidia, at the commemorative event. "It is the very first time in recent American history that the single most important chip is being manufactured here in the United States by the most advanced fab, by TSMC, here in the United States. This is the vision of President Trump of reindustrialization -- to bring back manufacturing to America, to create jobs, of course. Still, also, this is the single most vital manufacturing industry and the most important technology industry in the world." Production of Nvidia Blackwell B300 silicon (we presume these are the B300 chiplets, though as it is unconfirmed) in the U.S. -- one of the most complex chip ever created -- using TSMC's 4N fabrication process (a custom 4nm-class node for Nvidia) means that TSMC's Fab 21 is capable of making such large chips presumably with good yields (which apparently took some time to achieve), which may indicate that the fab is indeed as capable as ones that TSMC runs in Taiwan (something that we have already heard from TSMC's own comments, but those were made about smaller chips). Strategically, it fulfills a key goal of the U.S. government's industrial policy: bringing more advanced semiconductor manufacturing to American soil. Therefore, Nvidia can now claim that it produces one of its most essential products in the U.S. and avoid tariffs if they are imposed on Taiwan-made goods. The same applies to TSMC as it spreads its production across the world, reducing risks for its business from potential interruptions caused by China. Eventually, TSMC is set to build Fab 21 phases that will produce chips on N3, N2, A16, and A14 process technologies in Arizona. For decades, Nvidia -- the world's most valuable company with a market capitalization of $4.5 trillion -- has produced its chips exclusively in Taiwan with a brief production of the NV40 silicon at IBM's microelectronics fab in New York. Producing its key AI GPUs in the U.S. has a deep symbolic meaning for Nvidia, which is an American company. For the U.S., the achievement has a deep political meaning too. For decades, the world's most sophisticated chips were developed in the U.S. and then almost exclusively made in Taiwan, which created heavy dependence on a nation located in a high-risk geopolitical region. Producing Blackwell -- the most advanced and demanded AI GPU -- in the world, in the U.S., now gives Washington a tangible outcome from years of subsidies and incentives under the CHIPS Act (and before it), and pressure from the Trump administration. To some degree, this even gives Washington political leverage when negotiating with partners. While Nvidia's Blackwell silicon is now built in the USA, to make an actual Nvidia B300 out of them, they must be transported back to Taiwan and then integrated using CoWoS-L advanced packaging technologies with HBM3E memory at a TSMC facility. This not only makes these chips more expensive than those produced in Taiwan, but to a large degree, this strikes strategic and political advantages, leaving only the symbolic part. Still, this strategic dependence on advanced packaging in Taiwan is not going to last long. Both TSMC and Amkor are building advanced packaging facilities in the U.S., so when they come online, sometimes towards the end of the decade, that dependence will get significantly lower. Also, Micron and SK hynix are building DRAM production (Micron only) and HBM packaging facilities in the U.S., which will mark another significant step towards onshoring of production of strategically important components.

[2]

Nvidia's US chip production remains constrained by packaging

AI arms dealer relies on Taiwanese advanced packaging plants for top-specced GPUs US manufacturing of Nvidia GPUs is underway and CEO Jensen Huang is celebrating the first Blackwell wafer to come out of TSMC's Arizona chip factory. However, to be part of a complete product, those chips may need to visit Taiwan. Nvidia first announced plans to produce chips at Fab21 just six months ago.. Speaking during an event in Phoenix on Friday, Huang lauded TSMC's manufacturing prowess while pandering to US President Donald Trump's America First agenda. "This is the vision of President Trump of reindustrialization -- to bring back manufacturing to America, to create jobs, of course, but also this is the single most vital manufacturing industry and the most important technology industry in the world," he said. But while the silicon may be homegrown, Nvidia remains reliant on Taiwanese packaging plants to turn those wafers into its most powerful and highest-demand GPUs. Modern GPUs are composed of multiple compute and memory dies. The company's Blackwell family of datacenter chips feature two reticle-sized compute dies along with eight stacks of HBM3e memory, all stitched together using TSMC's CoWoS packaging tech. Up to this point, all of TSMC's packaging facilities have been located in Taiwan. Amkor, an outsourced semiconductor assembly and test services (OSAT) provider, is working on building an advanced packaging plant in the US capable of stitching together silicon dies using TSMC's chip-on-wafer-on-substrate (CoWoS) tech. But until it's done - expected in 2027 or 2028 - the next stop for Nvidia's wafers will likely be Taiwan. During TSMC's Q3 earnings call last week, CEO C.C. Wei confirmed the Amkor plan was moving forward, but the site was only now breaking ground. It's worth noting that, while Nvidia's most potent accelerators rely on CoWoS, not all of its Blackwell chips do. The RTX Pro 6000, a 96GB workstation and server card aimed at AI inference, data visualization, and digital twins doesn't feature a single GPU die fed by GDDR7 memory rather than HBM3e. This means Nvidia doesn't need CoWoS to produce the chip. The same is true for much of Nvidia's RTX family of gaming cards. Long-term, Nvidia isn't limited to TSMC or Amkor for packaging either. Nvidia has already announced plans to produce GPU tiles built by TSMC for Intel client processors that will presumably make use of the x86 giant's EMIB and/or Foveros advanced packaging technologies. Nvidia hasn't said which are the first Blackwell wafers to roll off Fab21's production line. El Reg has reached out for clarification; we'll let you know what we hear back. ®

[3]

Nvidia has produced the first Blackwell wafer entirely on US soil

* Nvidia and TSMC produced the first Blackwell chip in the U.S., built at TSMC Arizona. * Administration tariffs spurred onshoring pressure; this move echoes the push to bring manufacturing back. * U.S.-made Blackwell chips could cement America as an AI hardware hub and create local jobs. One of the biggest focuses of President Trump's term is bringing more production onto US turf. People have had differing opinions on whether or not this was a good idea, but Trump himself didn't leave much wiggle room. With tariffs having a huge effect on outsourcing hardware from other countries, the President's message was clear: move production over to the US, or pay up. Well, it seems that some big tech companies are beginning to warm to the former option. Nvidia has revealed its first Blackwell chip manufactured within the US, and it may signify a shift in how American companies get their products made. Nvidia shows off the first-ever Blackwell wafer that's "made in America" In a press release on the Nvidia news site, the company announces that it teamed up with TSMC to get the first-ever Blackwell wafer produced on US soil. Nvidia's CEO, Jensen Huang, took to the stage to sign the wafer and took some time to reflect on how this breakthrough will change how Nvidia's products are produced: "This is a historic moment for several reasons. It's the very first time in recent American history that the single most important chip is being manufactured here in the United States by the most advanced fab, by TSMC, here in the United States. This is the vision of President Trump of reindustrialization -- to bring back manufacturing to America, to create jobs, of course, but also, this is the single most vital manufacturing industry and the most important technology industry in the world." Ray Chuang, CEO of TSMC Arizona, also had some nice things to say about the partnership: "To go from arriving in Arizona to delivering the first U.S.-made NVIDIA Blackwell chip in just a few short years represents the very best of TSMC. This milestone is built on three decades of partnership with NVIDIA -- pushing the boundaries of technology together -- and on the unwavering dedication of our employees and the local partners who helped to make TSMC Arizona possible." Nvidia goes on to claim that onshoring the production of these chips is "paving the way for sustained American leadership in artificial intelligence." As such, it'll be exciting to see where Nvidia goes from here. If the company can truly make its US-based operations flourish, it may help America become the central hub for all things AI, both in terms of software and hardware. We'll have to wait and see how things shake out from here on. Maybe AMD's claims of beating Blackwell may still come true?

[4]

NVIDIA shows off its first Blackwell wafer manufactured in the US

NVIDIA has taken a big step towards strengthening its domestic chip manufacturing, revealing the first Blackwell wafer made in the US. The hardware company assembled the wafer, which is the base material for NVIDIA's AI chips, in TSMC's semiconductor manufacturing facility in Phoenix, Arizona. NVIDIA revealed its Blackwell platform last year, boasting a goal of revolutionizing the AI industry through tech giants like Amazon, Google, OpenAI and others who already committed to adopting the next-gen architecture. NVIDIA said the latest platform was more powerful and translated to 25x less cost and energy consumption compared to its predecessor. Now that Blackwell wafers can be made at the TSMC plant, NVIDIA can better insulate itself from the ever-evolving tariff situation and geopolitical tensions. "It's the very first time in recent American history that the single most important chip is being manufactured here in the United States by the most advanced fab, by TSMC, here in the United States," Jensen Huang, NVIDIA's founder and CEO, said at the celebration event. With NVIDIA's Blackwell architecture ready for the volume production stage, the company is still working on expanding its manufacturing footprint across the US. Earlier this year, NVIDIA said it had plans to funnel half a trillion dollars towards building AI infrastructure in the US through partnerships with TSMC, Foxconn and other companies.

[5]

The Engines of American-Made Intelligence: NVIDIA and TSMC Celebrate First NVIDIA Blackwell Wafer Produced in the US

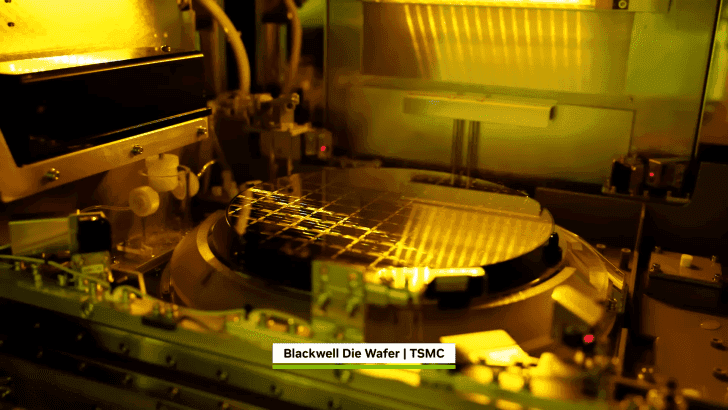

The celebration showcased how manufacturing the world's AI technology stack in America will fuel innovation and bolster the US supply chain. AI has ignited a new industrial revolution. NVIDIA and TSMC are working together to build the infrastructure that powers the world's AI factories, right here in America. NVIDIA founder and CEO Jensen Huang today visited TSMC's semiconductor manufacturing facility in Phoenix to celebrate the first NVIDIA Blackwell wafer produced on U.S. soil, representing that Blackwell has reached volume production. Onstage at the celebration, Huang joined Y.L. Wang, vice president of operations at TSMC, to sign the Blackwell wafer, commemorating a milestone that showcases how the engines of the world's AI infrastructure are now being constructed domestically. This bolsters the U.S. supply chain and onshores the AI technology stack that will turn data into intelligence and secure America's leadership for the AI era. "This is a historic moment for several reasons. It's the very first time in recent American history that the single most important chip is being manufactured here in the United States by the most advanced fab, by TSMC, here in the United States," Huang said at the event. "This is the vision of President Trump of reindustrialization -- to bring back manufacturing to America, to create jobs, of course, but also, this is the single most vital manufacturing industry and the most important technology industry in the world." "To go from arriving in Arizona to delivering the first U.S.-made NVIDIA Blackwell chip in just a few short years represents the very best of TSMC," said Ray Chuang, CEO of TSMC Arizona. "This milestone is built on three decades of partnership with NVIDIA -- pushing the boundaries of technology together -- and on the unwavering dedication of our employees and the local partners who helped to make TSMC Arizona possible." The wafer -- the base material for semiconductors -- will go through a complex process of layering, patterning, etching and dicing before taking shape as the ultra-high-performance, accelerated AI chip the NVIDIA Blackwell architecture offers. TSMC Arizona will produce advanced technologies including two-, three- and four-nanometer chips, as well as A16 chips, all essential for applications like AI, telecommunications and high-performance computing. Onshoring World-Class AI Chipmaking to American Soil America-based manufacturing is crucial to meeting the growing demand for AI. Today's achievement marks a huge step forward in semiconductor manufacturing and AI development in the U.S., paving the way for sustained American leadership in artificial intelligence. NVIDIA Blackwell GPUs offer exceptional performance, return on investment and energy efficiency for AI inference. In addition, NVIDIA plans to deploy its advanced AI, robotics and digital twin technologies to design and operate new U.S. manufacturing facilities. Learn more about how NVIDIA technologies accelerate innovation for America's enterprises, government organizations, researchers and startups at NVIDIA GTC Washington, D.C., running Oct. 27-29.

[6]

Exclusive: Nvidia and TSMC unveil first Blackwell chip wafer made in U.S.

Why it matters: This milestone represents some of the first fruits of the Trump administration's push to build AI technology in the U.S., and stay ahead in the race to control the future of artificial intelligence. Driving the news: Nvidia founder and CEO Jensen Huang visited TSMC's semiconductor manufacturing facility in Phoenix on Friday to announce the advance. What they're saying: "Nvidia and TSMC are working together to build the infrastructure that powers the world's AI factories, right here in America," Nvidia said in a blog post. * "TSMC Arizona is expected to create thousands of high-tech jobs and attract a broad ecosystem of suppliers," Nvidia and TSMC said in a joint statement. Yes, but: The wafer is a crucial first step in re-shoring critical chip production in the U.S., but there's still a long way to go before the country's chip demand could be free of dependency on companies and factories overseas. The bottom line: Intense efforts to re-shore key parts of the AI economy are starting to pay off. This is a developing story.

[7]

The first US-made Nvidia Blackwell wafer just came out of TSMC Arizona, but don't get carried away thinking about RTX 50 Supers yet

Chip manufacturing moving over to the US might seem like a 2025 phenomenon, thanks to the Trump administration's very vocal pushing towards this goal, but TSMC, the world's biggest computer chip manufacturer, approved production of its Arizona plant back in 2020. The US-based fabrication plant (fab) started churning out wafers last year, and it has now produced the first-ever US-made Nvidia Blackwell wafer. Nvidia CEO Jensen Huang said, "This is a historic moment for several reasons. It's the very first time in recent American history that the single most important chip is being manufactured here in the United States by the most advanced fab, by TSMC, here in the United States." And although Huang would, of course, say this about Nvidia's own chip, it is probably true that Blackwell is the "single most important chip." That's because it's far and away the chip that AI datacentre companies are clawing for. TSMC Arizona CEO Ray Chuang expressed the importance of the recent Blackwell chip: "To go from arriving in Arizona to delivering the first U.S.-made NVIDIA Blackwell chip in just a few short years represents the very best of TSMC." None of this is to say that the Arizona plant's Blackwell production will pad out supply right now -- one wafer doesn't necessarily signal mass production. And we should also remember that this is just a wafer, not a finished chip. The wafer, made on TSMC's 5 nm process (an Nvidia-specific 4NP node), still needs to be chopped up and packaged, meaning the silicon substrate needs to be encased and affixed to surrounding components, including all those stacks of high bandwidth memory (HBM). This packaging can't be done in the US right now, so the chips will have to be shipped back to Taiwan for those crucial final touches. In the future, packaging might be done in the US, though. Earlier in the year, Trump and TSMC announced a $100 billion investment plan in the US, and part of that included plans for two advanced packaging facilities in addition to chip fabs. Of course, we PC gamers are primarily interested in RTX 50-series GPUs, which are also derived from Blackwell architecture. It might be nice to think about possible upcoming RTX 50-series Super cards being made from this plant, but that's unlikely. Scale will be required for the refreshed batch of RTX 50 cards, so those will likely have to come out of Taiwan. Still, it's promising for the future, especially given the ongoing diplomatic tensions surrounding Taiwan. From a consumer perspective, more chips in more locations is always good, and it's obviously good news from a US standpoint: the world's biggest AI company, an American company, having its latest and greatest chips made in the US.

[8]

NVIDIA, TSMC Produce First Blackwell Wafer in the US, Boosting Domestic AI Chip Manufacturing | AIM

The Blackwell wafer is the base material for semiconductors and will undergo layering, patterning, etching, and dicing before becoming NVIDIA's AI chip. NVIDIA and TSMC have produced the first NVIDIA Blackwell wafer on US soil, marking the start of volume production of the AI chip in America. The milestone highlights efforts to onshore semiconductor manufacturing and strengthen the US supply chain. NVIDIA founder and CEO Jensen Huang visited TSMC's Phoenix facility to celebrate the achievement and signed the Blackwell wafer alongside Y.L. Wang, TSMC vice president of operations. "It's the very first time in recent American history that the single most important chip is being manufactured here in the United States by the most advanced fab, by TSMC, here in the United States," Huang said. "This is the vision of President Trump of reindustrialisation -- to bring back manufacturing to America, to create jobs, of course, but also, this is the single most vital manufacturing industry and the most important technology industry in the world." Ray Chuang, CEO of TSMC Arizona, said the milestone reflects decades of collaboration with NVIDIA. "To go from arriving in Arizona to delivering the first US-made NVIDIA Blackwell chip in just a few short years represents the very best of TSMC," he said. "This milestone is built on three decades of partnership with NVIDIA -- pushing the boundaries of technology together -- and on the unwavering dedication of our employees and the local partners who helped to make TSMC Arizona possible." The Blackwell wafer is the base material for semiconductors and will undergo layering, patterning, etching, and dicing before becoming NVIDIA's AI chip. TSMC Arizona will produce two-, three-, and four-nanometer chips, as well as A16 chips, for AI, telecommunications, and high-performance computing applications. NVIDIA said domestic manufacturing is critical to meeting AI demand and plans to use its AI, robotics, and digital twin technologies to design and operate new U.S. manufacturing facilities.

[9]

Nvidia begins volume production of Blackwell chips in TSMC's Arizona fab - SiliconANGLE

Nvidia begins volume production of Blackwell chips in TSMC's Arizona fab Nvidia Corp. today announced that its Blackwell chips have entered volume production in Taiwan Semiconductor Manufacturing Co.'s Arizona fab. The news marks a major milestone in the graphics card maker's efforts to bring more of its supply chain to the U.S. TSMC, the world's largest contract chipmaker, opened its first fab near Phoenix late last year. The facility makes processors based on the company's four-nanometer manufacturing process. The node is two generations behind TSMC's newest two-nanometer technology, which is slated to enter mass production later this year. Nvidia is not the fab's first customer. Late last year, Apple Inc. reportedly started using the facility to produce the A16 Bionic system-on-chip that powers its 2022 iPhone lineup. Nvidia Chief Executive Officer Jensen Huang visited the fab today on occasion of the company's manufacturing milestone and signed the first Blackwell wafer produced on-site. "It's the very first time in recent American history that the single most important chip is being manufactured here in the United States by the most advanced fab," Huang said. The Blackwell architecture introduces several improvements over Nvidia's previous-generation Hopper chip design. There's a new version of the built-in Transformer Engine, a module optimized to run large language models. Nvidia has also added a component called the Decompression Engine that is designed to speed up database queries. The Blackwell architecture is the basis of several Nvidia chips. The most advanced product, the Blackwell Ultra, can provide 15 petaflops of performance for AI workloads. Nvidia has also incorporated the architecture into several of its consumer graphics cards and the chip that powers its newly launched DGX Spark workstation. TSMC plans to build two more fabs in Arizona by the end of the decade. One of them will be capable of making chips based on the company's upcoming A16 node, the planned successor to its two-nanometer process. The technology will feature enhanced power delivery wiring and transistors made of nanosheets. Nvidia's collaboration with TSMC is part of a broad manufacturing initiative that also involves other suppliers. In Arizona, the graphics card maker will partner with Amkor Technology Inc. and SPIL Co. Ltd. to produce chip packaging. That's the technology Nvidia uses to link together the different components of a Blackwell chip into a single product. The company's flagship graphics cards comprise two separate compute dies and HSM memory modules. In Texas, Nvidia will work with partners to build two "supercomputer manufacturing plants." The company sells a line of AI appliances called the DGX series that can be assembled into supercomputers. Nvidia expects the factories to begin mass production in the next 12-15 months.

[10]

NVIDIA unveils first Blackwell chip wafer made at TSMC Arizona, pushes 'Made in USA' narrative

TL;DR: NVIDIA CEO Jensen Huang and TSMC celebrated the first NVIDIA Blackwell wafer produced in the U.S. at TSMC's Arizona facility, marking a key milestone in onshoring advanced AI chip manufacturing. This strengthens the U.S. supply chain and secures America's leadership in AI technology and semiconductor innovation. NVIDIA CEO and founder Jensen Huang visited TSMC's semiconductor manufacturing facility in Phoenix, Arizona to celebrate something huge: the first NVIDIA Blackwell wafer produced on American soil. To celebrate the milestone, Huang was joined by Y.L. Wang, the vice president of operations at TSMC, to personally sign the NVIDIA Blackwell wafer, commemorating a milestone that as NVIDIA writes "showcases how the engines of the world's AI infrastructure are now being constructed domestically". This move strengthens the US supply chain as well as onshores the AI technology stack that will turn data into intelligence, and secure America's leadership for the AI era. Huang said at the event: "This is a historic moment for several reasons. It's the very first time in recent American history that the single most important chip is being manufactured here in the United States by the most advanced fab, by TSMC, here in the United States. This is the vision of President Trump of reindustrialization - to bring back manufacturing to America, to create jobs, of course, but also, this is the single most vital manufacturing industry and the most important technology industry in the world".

[11]

NVIDIA's first US-made Blackwell wafer rolls out of TSMC's Arizona fab

Producing these wafers domestically allows NVIDIA to better insulate itself from evolving tariff situations and geopolitical tensions. NVIDIA revealed its first Blackwell wafer manufactured in the United States, assembled at TSMC's semiconductor facility in Phoenix, Arizona. The hardware company's action is part of an effort to strengthen its domestic chip manufacturing capabilities for its advanced AI hardware. The company announced its Blackwell platform last year, with commitments from technology firms including Amazon, Google, and OpenAI to adopt the next-generation architecture. NVIDIA stated the platform is designed to be more powerful, delivering what it reports as 25-times lower cost and energy consumption when compared to its predecessor. The Blackwell architecture, which serves as the base for the company's AI chips, is now ready for the volume production stage. Producing these wafers domestically allows NVIDIA to better insulate itself from evolving tariff situations and geopolitical tensions. At a celebration event, founder and CEO Jensen Huang commented on the development. "It's the very first time in recent American history that the single most important chip is being manufactured here in the United States by the most advanced fab, by TSMC, here in the United States," Huang stated. NVIDIA is also actively working to expand its manufacturing footprint across the country. Earlier this year, the company detailed plans to invest $500 billion toward building AI infrastructure in the United States. This investment will be facilitated through partnerships with companies such as TSMC and Foxconn.

[12]

Nvidia, TSMC Unveil The First US-Made Blackwell Wafer, But Analyst Ming-Chi Kuo Flags An Overlooked Detail - NVIDIA (NASDAQ:NVDA), Apple (NASDAQ:AAPL)

Nvidia Corp (NASDAQ:NVDA) has introduced the first U.S.-made Blackwell wafer, a crucial component for AI chips, at Taiwan Semiconductor Manufacturing Co's (NYSE:TSM) facility in Phoenix. First US Blackwell Chip The unveiling of the Blackwell wafer is a response to the surging demand for AI chips. The wafer, which serves as the foundation for semiconductors, will undergo a series of intricate processes before transforming into the ultra-high-performance, accelerated AI chip offered by the NVIDIA Blackwell architecture, Nvidia announced on Friday. The Arizona facility of TSMC will manufacture advanced technologies, including two-, three-, and four-nanometer chips, as well as A16 chips, which are essential for AI, telecommunications, and high-performance computing, according to Nvidia. Nvidia's CEO, Jensen Huang, hailed the development as a "historic moment," marking the first time in recent American history that the most crucial chip is being produced in the U.S. by TSMC, the most advanced fab in the country. "This is the vision of President Trump of reindustrialization -- to bring back manufacturing to America, to create jobs.." added Huang. US Blackwell Wafer Still Needs Taiwan Analyst Ming-Chi Kuo on Sunday, notes that NVIDIA and TSMC's announcement masks a key detail: the first U.S.-made Blackwell wafer from Arizona still needs to be shipped to Taiwan for CoWoS advanced packaging. Since CoWoS, crucial for high-performance AI chips, remains Taiwan-dependent, full domestic production isn't expected until two years from now. See Also: Kevin Hart Once Revealed Investing In His Friends' Ideas Had Been An 'Endless Pit Of Bankruptcy' -- In Fact, One Such Idea Was His Worst Investment This development comes in the wake of Taiwan's rejection of the Trump administration's proposal for a 50-50 split in semiconductor production between the U.S. and Taiwan, earlier this month. This move by Nvidia could be seen as an attempt to address the structural issues within America's own chip ecosystem. It also comes on the heels of Apple Inc.'s (NASDAQ:AAPL) August deal with TSMC to secure nearly half of TSMC's initial 2nm chip production capacity. Apple has secured supply for its flagship device and created a "firewall" against Trump's proposed 100% semiconductor tariffs, leveraging its scale, planning, and U.S. investments to stay protected while competitors face risks. Price Action: On a year-to-date basis, shares of Nvidia and TSMC surged 32.47% and 46.38%, respectively, as per data from Benzinga Pro. READ NEXT: Nvidia's Real 'Bottleneck' Isn't Chips, It's Power, Says Beth Kindig, Tech Analyst Shares What It Means For AI Investors Image via Shutterstock Disclaimer: This content was partially produced with the help of AI tools and was reviewed and published by Benzinga editors. AAPLApple Inc$253.180.35%OverviewNVDANVIDIA Corp$183.790.31%TSMTaiwan Semiconductor Manufacturing Co Ltd$302.472.50%Market News and Data brought to you by Benzinga APIs

[13]

NVIDIA's First Arizona-Made Blackwell Wafer Exposes a Hidden Weakness: The U.S. Can Build Chips, But Must Send Them Abroad to Finish the Job

Well, NVIDIA had recently announced the first successful production of Blackwell chip wafers on American soil, but there's still an element of the AI supply chain that is yet to be brought in. For those unaware, NVIDIA's CEO Jensen Huang unveiled the first Blackwell chip wafer made in the US a few days ago at TSMC Arizona, and it was indeed a massive achievement for the 'Made in USA' narrative. However, there's still a key part of the AI supply chain that isn't with the US for now, which is why the first Blackwell wafer produced would likely be needed to fly back to Taiwan to get the AI chips carved out of the wafer successfully. If you still haven't guessed what we are talking about, it's the lack of advanced packaging services in America, such as TSMC's CoWoS. Advanced packaging has played a vital role in the semiconductor industry with the advent of the AI frenzy, and in this case, in particular, the Blackwell chip wafer being held by Jensen himself is a rather 'unrefined' piece of silicon. In a usual process, the wafer will be sliced into multiple dies, with each die being connected and mounted onto a substrate, and then interconnected using technologies like TSMC's CoWoS or Intel's EMIB. Packaging is a crucial part of scaling up the performance of AI chips, since it basically stacking and integrating dies with short interconnects. The U.S. still lacks sufficient advanced packaging services, which is why firms like TSMC need to send wafers being produced in America to locations like Taiwan, where they are then processed and integrated with packaging technologies. The 'back-end' of the AI chip supply chain isn't sufficiently available in the US at all, which produces a constraint for manufacturers in the nation, as well as adding extra costs to the end product, or in this case, the Blackwell AI chips. However, the industry has recognized the problem, and here's how it is being mitigated. TSMC has already announced plans to develop advanced packaging services in the US, as a part of its multi-billion dollar investment in the region, but setting up such facilities could take years, since work has to be done from 'ground zero'. However, the Taiwan giant has plans to collaborate with Amkor, which is an American product packaging and test services provider, to speed up the process of bringing technologies like CoWoS into the US. The goal here is to contract turnkey advanced packaging and test services from Amkor to ensure a quick time-to-market process. The US has recognized the need to have a sufficient supply chain, covering both front-end and back-end elements, and with the investments from the likes of TSMC, the process has sped up massively, to the point where America is producing one of the world's most powerful AI chips domestically.

[14]

NVIDIA Embraces the 'Made in USA' Narrative, As Jensen Huang Unveils the First Blackwell Chip Wafer Produced by TSMC Arizona

NVIDIA's CEO has revealed that TSMC has produced the first Blackwell chip wafer in America, a massive development towards the future of manufacturing in the nation. Since the Trump administration took office, efforts to bring manufacturing back to the US have influenced almost every tech giant, with NVIDIA leading the way. The firm announced plans to invest $500 billion in American manufacturing, prompting suppliers like Foxconn and Quanta to set up manufacturing facilities in the US. In a blog post shared by Team Green, it is revealed that TSMC Arizona has begun manufacturing Blackwell on American soil, and Jensen Huang himself paid a visit to Phoenix to celebrate this massive achievement. This is a historic moment for several reasons. It's the very first time in recent American history that the single most important chip is being manufactured here in the United States by the most advanced fab, by TSMC, here in the United States. This is the vision of President Trump of reindustrialization -- to bring back manufacturing to America, to create jobs, of course, but also, this is the single most vital manufacturing industry and the most important technology industry in the world. - NVIDIA's CEO Jensen Huang NVIDIA's CEO was also joined by the CEO of TSMC Arizona, Ray Chuang, who celebrated the Taiwan giant's rapid progress on manufacturing in the US. The Blackwell chip wafer being produced in Arizona means that NVIDIA and its partners have brought the production of the world's most advanced AI chips to America. If someone had discussed this achievement a few years ago, it would've been seen as impossible at that time. More importantly, NVIDIA also states that TSMC plans to introduce "two-, three- and four-nanometer chips, as well as A16 chips," into Arizona. For those unaware, TSMC Arizona announced its development into Blackwell production back in April, and the firm has managed to produce the first chip wafer in just six months, which is yet again a standard only the Taiwan giant can achieve. Of course, wafer is one of the crucial stages of manufacturing, but it is also followed by processes such as "layering, patterning, etching, and dicing" before it turns into deployable AI chips. It appears that TSMC's US operations will continue to grow from hereon. More importantly, the chip giant has revealed intentions to introduce cutting-edge processes in the US, such as the A16 (1.6nm), which means that America is emerging as the next semiconductor hub, alongside Taiwan.

[15]

Nvidia unveils first Blackwell chip wafer made with TSMC in US

(Reuters) -Nvidia uveiled on Friday the first U.S.-made Blackwell wafer, produced at TSMC's semiconductor manufacturing facility in Phoenix, as demand for AI chips accelerates. Companies have been racing to meet the broader AI industry's voracious appetite for computing power as they develop AI technology that meets or exceeds human intelligence. The move "bolsters the U.S. supply chain and onshores the AI technology stack that will turn data into intelligence and secure America's leadership for the AI era," Nvidia said in a blog post. It also aligns with President Donald Trump's efforts to strengthen U.S. technology and manufacturing leadership. TSMC's Arizona facility will produce advanced technologies including two-, three- and four-nanometer chips, as well as A16 chips, that are essential for applications like AI, telecommunications and high-performance computing, Nvidia said. There has recently been a flurry of mega deals between AI firms and chipmakers such as Nvidia, AMD and Broadcom to build data center capacity. TSMC, the world's biggest producer of advanced chips, raised its full-year revenue forecast on Thursday on a bullish outlook for AI spending after posting a record profit that blew past market estimates. (Reporting by Juby Babu in Mexico City; Editing by Alan Barona)

Share

Share

Copy Link

Nvidia and TSMC have produced the first Blackwell wafer in the US, signaling a shift in semiconductor manufacturing. While this marks a significant step towards American chip production, the process still requires completion in Taiwan.

Milestone in US Chip Manufacturing

Nvidia and TSMC have reached a significant milestone in semiconductor manufacturing with the production of the first Blackwell wafer at TSMC's Fab 21 near Phoenix, Arizona

1

5

. This achievement marks the first time in recent American history that one of the world's most advanced and important chips is being manufactured on US soil3

.

Source: NVIDIA

Strategic Implications and Political Context

The production of Nvidia's Blackwell B300 silicon using TSMC's 4N fabrication process in the US aligns with the government's industrial policy of bringing advanced semiconductor manufacturing to American soil

1

. This move is seen as a response to the Trump administration's push for reindustrialization and the creation of domestic jobs in critical technology sectors3

.Challenges and Limitations

Despite this progress, there's a significant caveat: the Blackwell silicon produced in the US still needs to be transported back to Taiwan for integration with HBM3E memory using TSMC's CoWoS-L advanced packaging technologies

1

2

. This dependency on Taiwanese facilities for advanced packaging somewhat diminishes the strategic and political advantages of US-based production.

Source: Wccftech

Related Stories

Future Prospects and Industry Impact

The achievement demonstrates that TSMC's Fab 21 is capable of producing complex chips with good yields, potentially indicating that the US facility is as capable as TSMC's Taiwan-based fabs

1

. Looking ahead, both TSMC and Amkor are building advanced packaging facilities in the US, which could significantly reduce dependence on Taiwan for these crucial processes by the end of the decade1

.Economic and Technological Implications

This development is expected to strengthen the US supply chain and onshore the AI technology stack, potentially securing America's leadership in the AI era

5

. Nvidia plans to deploy advanced AI, robotics, and digital twin technologies to design and operate new US manufacturing facilities, further bolstering domestic production capabilities5

.

Source: The Register

As the world's most valuable company with a market capitalization of $4.5 trillion, Nvidia's move to produce its key AI GPUs in the US carries significant economic weight and symbolic meaning

1

. This shift in manufacturing strategy could potentially reshape the global semiconductor landscape and reinforce America's position as a hub for AI hardware development.References

Summarized by

Navi

[1]

[2]

[3]

Related Stories

Recent Highlights

1

Pentagon threatens to cut Anthropic's $200M contract over AI safety restrictions in military ops

Policy and Regulation

2

ByteDance's Seedance 2.0 AI video generator triggers copyright infringement battle with Hollywood

Policy and Regulation

3

OpenAI closes in on $100 billion funding round with $850 billion valuation as spending plans shift

Business and Economy