NVIDIA Expands Omniverse Platform to Revolutionize AI Factory Design and Industrial Robotics

5 Sources

5 Sources

[1]

AI Factories Are Redefining Data Centers and Enabling the Next Era of AI

AI is fueling a new industrial revolution -- one driven by AI factories. Unlike traditional data centers, AI factories do more than store and process data -- they manufacture intelligence at scale, transforming raw data into real-time insights. For enterprises and countries around the world, this means dramatically faster time to value -- turning AI from a long-term investment into an immediate driver of competitive advantage. Companies that invest in purpose-built AI factories today will lead in innovation, efficiency and market differentiation tomorrow. While a traditional data center typically handles diverse workloads and is built for general-purpose computing, AI factories are optimized to create value from AI. They orchestrate the entire AI lifecycle -- from data ingestion to training, fine-tuning and, most critically, high-volume inference. For AI factories, intelligence isn't a byproduct but the primary one. This intelligence is measured by AI token throughput -- the real-time predictions that drive decisions, automation and entirely new services. While traditional data centers aren't disappearing anytime soon, whether they evolve into AI factories or connect to them depends on the enterprise business model. Regardless of how enterprises choose to adapt, AI factories powered by NVIDIA are already manufacturing intelligence at scale, transforming how AI is built, refined and deployed. The Scaling Laws Driving Compute Demand Over the past few years, AI has revolved around training large models. But with the recent proliferation of AI reasoning models, inference has become the main driver of AI economics. Three key scaling laws highlight why: Traditional data centers aren't designed for this new era of AI. AI factories are purpose-built to optimize and sustain this massive demand for compute, providing an ideal path forward for AI inference and deployment. Reshaping Industries and Economies With Tokens Across the world, governments and enterprises are racing to build AI factories to spur economic growth, innovation and efficiency. The European High Performance Computing Joint Undertaking recently announced plans to build seven AI factories in collaboration with 17 European Union member nations. This follows a wave of AI factory investments worldwide, as enterprises and countries accelerate AI-driven economic growth across every industry and region: These initiatives underscore a global reality: AI factories are quickly becoming essential national infrastructure, on par with telecommunications and energy. Inside an AI Factory: Where Intelligence Is Manufactured Foundation models, secure customer data and AI tools provide the raw materials for fueling AI factories, where inference serving, prototyping and fine-tuning shape powerful, customized models ready to be put into production. As these models are deployed into real-world applications, they continuously learn from new data, which is stored, refined and fed back into the system using a data flywheel. This cycle of optimization ensures AI remains adaptive, efficient and always improving -- driving enterprise intelligence at an unprecedented scale. An AI Factory Advantage With Full-Stack NVIDIA AI NVIDIA delivers a complete, integrated AI factory stack where every layer -- from the silicon to the software -- is optimized for training, fine-tuning, and inference at scale. This full-stack approach ensures enterprises can deploy AI factories that are cost effective, high-performing and future-proofed for the exponential growth of AI. With its ecosystem partners, NVIDIA has created building blocks for the full-stack AI factory, offering: The heart of any AI factory is its compute power. From NVIDIA Hopper to NVIDIA Blackwell, NVIDIA provides the world's most powerful accelerated computing for this new industrial revolution. With the NVIDIA Blackwell Ultra-based GB300 NVL72 rack-scale solution, AI factories can achieve up to 50X the output for AI reasoning, setting a new standard for efficiency and scale. The NVIDIA DGX SuperPOD is the exemplar of the turnkey AI factory for enterprises, integrating the best of NVIDIA accelerated computing. NVIDIA DGX Cloud provides an AI factory that delivers NVIDIA accelerated compute with high performance in the cloud. Global systems partners are building full-stack AI factories for their customers based on NVIDIA accelerated computing -- now including the NVIDIA GB200 NVL72 and GB300 NVL72 rack-scale solutions. Advanced Networking Moving intelligence at scale requires seamless, high-performance connectivity across the entire AI factory stack. NVIDIA NVLink and NVLink Switch enable high-speed, multi-GPU communication, accelerating data movement within and across nodes. AI factories also demand a robust network backbone. The NVIDIA Quantum InfiniBand, NVIDIA Spectrum-X Ethernet, and NVIDIA BlueField networking platforms reduce bottlenecks, ensuring efficient, high-throughput data exchange across massive GPU clusters. This end-to-end integration is essential for scaling out AI workloads to million-GPU levels, enabling breakthrough performance in training and inference. Infrastructure Management and Workload Orchestration Businesses need a way to harness the power of AI infrastructure with the agility, efficiency and scale of a hyperscaler, but without the burdens of cost, complexity and expertise placed on IT. With NVIDIA Run:ai, organizations can benefit from seamless AI workload orchestration and GPU management, optimizing resource utilization while accelerating AI experimentation and scaling workloads. NVIDIA Mission Control software, which includes NVIDIA Run:ai technology, streamlines AI factory operations from workloads to infrastructure while providing full-stack intelligence that delivers world-class infrastructure resiliency. The Largest AI Inference Ecosystem AI factories need the right tools to turn data into intelligence. The NVIDIA AI inference platform, spanning the NVIDIA TensorRT ecosystem, NVIDIA Dynamo and NVIDIA NIM microservices -- all part (or soon to be part) of the NVIDIA AI Enterprise software platform -- provides the industry's most comprehensive suite of AI acceleration libraries and optimized software. It delivers maximum inference performance, ultra-low latency and high throughput. Storage and Data Platforms Data fuels AI applications, but the rapidly growing scale and complexity of enterprise data often make it too costly and time-consuming to harness effectively. To thrive in the AI era, enterprises must unlock the full potential of their data. The NVIDIA AI Data Platform is a customizable reference design to build a new class of AI infrastructure for demanding AI inference workloads. NVIDIA-Certified Storage partners are collaborating with NVIDIA to create customized AI data platforms that can harness enterprise data to reason and respond to complex queries. Blueprints for Design and Optimization To design and optimize AI factories, teams can use the NVIDIA Omniverse Blueprint for AI factory design and operations. The blueprint enables engineers to design, test and optimize AI factory infrastructure before deployment using digital twins. By reducing risk and uncertainty, the blueprint helps prevent costly downtime -- a critical factor for AI factory operators. For a 1 gigawatt-scale AI factory, every day of downtime can cost over $100 million. By solving complexity upfront and enabling siloed teams in IT, mechanical, electrical, power and network engineering to work in parallel, the blueprint accelerates deployment and ensures operational resilience. Reference Architectures NVIDIA Enterprise Reference Architectures and NVIDIA Cloud Partner Reference Architectures provide a roadmap for partners designing and deploying AI factories. They help enterprises and cloud providers build scalable, high-performance and secure AI infrastructure based on NVIDIA-Certified Systems with the NVIDIA AI software stack and partner ecosystem. Every layer of the AI factory stack relies on efficient computing to meet growing AI demands. NVIDIA accelerated computing serves as the foundation across the stack, delivering the highest performance per watt to ensure AI factories operate at peak energy efficiency. With energy-efficient architecture and liquid cooling, businesses can scale AI while keeping energy costs in check. Flexible Deployment for Every Enterprise With NVIDIA's full-stack technologies, enterprises can easily build and deploy AI factories, aligning with customers' preferred IT consumption models and operational needs. Some organizations opt for on-premises AI factories to maintain full control over data and performance, while others use cloud-based solutions for scalability and flexibility. Many also turn to their trusted global systems partners for pre-integrated solutions that accelerate deployment. On Premises NVIDIA DGX SuperPOD is a turnkey AI factory infrastructure solution that provides accelerated infrastructure with scalable performance for the most demanding AI training and inference workloads. It features a design-optimized combination of AI compute, network fabric, storage and NVIDIA Mission Control software, empowering enterprises to get AI factories up and running in weeks instead of months -- and with best-in-class uptime, resiliency and utilization. AI factory solutions are also offered through the NVIDIA global ecosystem of enterprise technology partners with NVIDIA-Certified Systems. They deliver leading hardware and software technology, combined with data center systems expertise and liquid-cooling innovations, to help enterprises de-risk their AI endeavors and accelerate the return on investment of their AI factory implementations. These global systems partners are providing full-stack solutions based on NVIDIA reference architectures -- integrated with NVIDIA accelerated computing, high-performance networking and AI software -- to help customers successfully deploy AI factories and manufacture intelligence at scale. In the Cloud For enterprises looking to use a cloud-based solution for their AI factory, NVIDIA DGX Cloud delivers a unified platform on leading clouds to build, customize and deploy AI applications. Every layer of DGX Cloud is optimized and fully managed by NVIDIA, offering the best of NVIDIA AI in the cloud, and features enterprise-grade software and large-scale, contiguous clusters on leading cloud providers, offering scalable compute resources ideal for even the most demanding AI training workloads. DGX Cloud also includes a dynamic and scalable serverless inference platform that delivers high throughput for AI tokens across hybrid and multi-cloud environments, significantly reducing infrastructure complexity and operational overhead. By providing a full-stack platform that integrates hardware, software, ecosystem partners and reference architectures, NVIDIA is helping enterprises build AI factories that are cost effective, scalable and high-performing -- equipping them to meet the next industrial revolution.

[2]

AI Factories, Built Smarter: New Omniverse Blueprint Advances AI Factory Design and Simulation

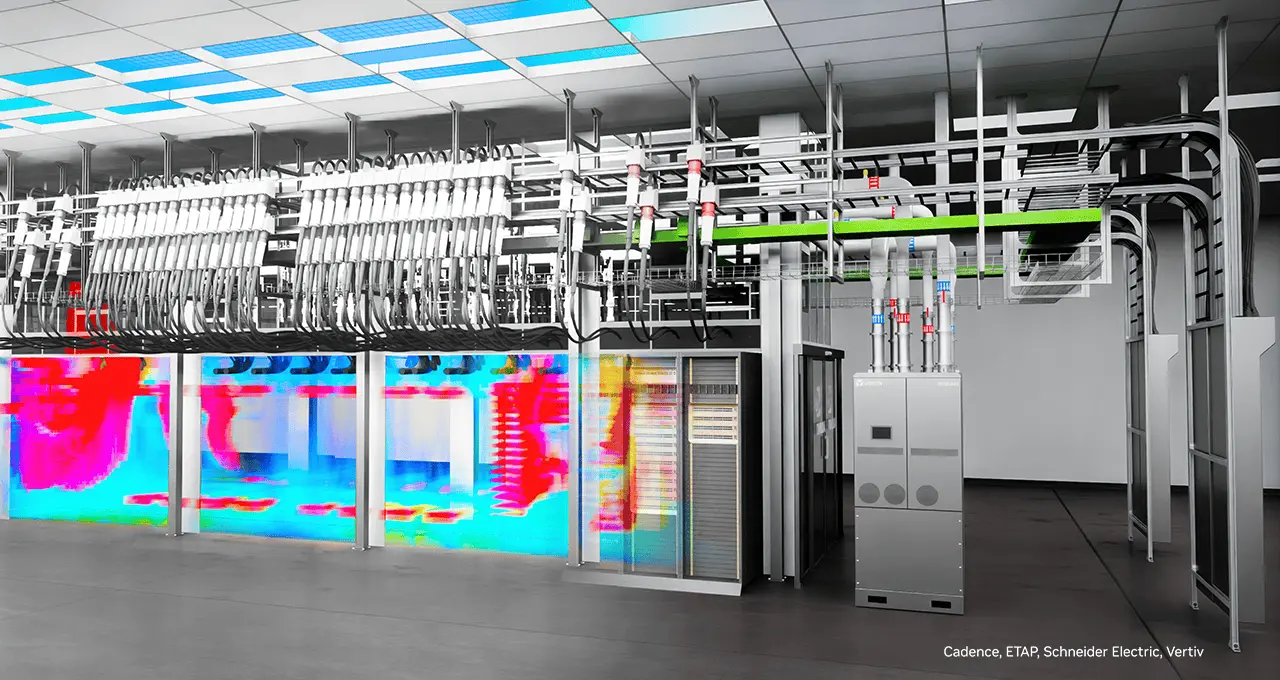

The blueprint, connected to Cadence, ETAP, Schneider Electric and Vertiv solutions, lets engineers design, test and optimize a new generation of intelligence manufacturing data centers using digital twins. AI is now mainstream and driving unprecedented demand for AI factories -- purpose-built infrastructure dedicated to AI training and inference -- and the production of intelligence. Many of these AI factories will be gigawatt-scale. Bringing up a single gigawatt AI factory is an extraordinary act of engineering and logistics -- requiring tens of thousands of workers across suppliers, architects, contractors and engineers to build, ship and assemble nearly 5 billion components and over 210,000 miles of fiber cable. To help design and optimize these AI factories, NVIDIA today unveiled at GTC the NVIDIA Omniverse Blueprint for AI factory design and operations. During his GTC keynote, NVIDIA founder and CEO Jensen Huang showcased how NVIDIA's data center engineering team developed an application on the Omniverse Blueprint to plan, optimize and simulate a 1 gigawatt AI factory. Connected to leading simulation tools such as Cadence Reality Digital Twin Platform and ETAP, the engineering teams can test and optimize power, cooling and networking long before construction starts. Engineering AI Factories: A Simulation-First Approach The NVIDIA Omniverse Blueprint for AI factory design and operations uses OpenUSD libraries that enable developers to aggregate 3D data from disparate sources such as the building itself, NVIDIA accelerated computing systems and power or cooling units from providers such as Schneider Electric and Vertiv. By unifying the design and simulation of billions of components, the blueprint helps engineers address complex challenges like: Breaking Down Engineering Silos With Omniverse One of the biggest challenges in AI factory construction is that different teams -- power, cooling and networking -- operate in silos, leading to inefficiencies and potential failures. Using the blueprint, engineers can now: By integrating real-time simulation across disciplines, the blueprint allows engineering teams to explore various configurations to model cost of ownership and optimize power utilization. Real-Time Simulations for Faster Decision-Making In Huang's demo, engineers adjust AI factory configurations in real time -- and instantly see the impact. For example, a small tweak in cooling layout significantly improved efficiency -- a detail that could have been missed on paper. And instead of waiting hours for simulation results, teams could test and refine strategies in just seconds. Once an optimal design was finalized, Omniverse streamlined communication with suppliers and construction teams -- ensuring that what gets built matches the model, down to the last detail. Future-Proofing AI Factories AI workloads aren't static. The next wave of AI applications will push power, cooling and networking demands even further. The Omniverse Blueprint for AI factory design and operations helps ensure AI factories are ready by offering: And when planning for retrofits and upgrades, users can easily test and simulate cost and downtime -- delivering a future-proof AI factory. For AI factory operators, staying ahead isn't just about efficiency -- it's about preventing infrastructure failures that could cost millions of dollars per day. For a 1 gigawatt AI factory, every day of downtime can cost over $100 million. By solving infrastructure challenges in advance, the blueprint reduces both risk and time to deployment. Road to Agentic AI for AI Factory Operation NVIDIA is working on the next evolution of the blueprint to expand into AI-enabled operations, working with key companies such as Vertech and Phaidra. Vertech is collaborating with the NVIDIA data center engineering team on NVIDIA's advanced AI factory control system, which integrates IT and operational technology data to enhance resiliency and operational visibility. Phaidra is working with NVIDIA to integrate reinforcement-learning AI agents into Omniverse. These agents optimize thermal stability and energy efficiency through real-time scenario simulation, creating digital twins that continuously adapt to changing hardware and environmental conditions. The AI Data Center Boom AI is reshaping the global data center landscape. With $1 trillion projected for AI-driven data center upgrades, digital twin technology is no longer optional -- it's essential. The NVIDIA Omniverse Blueprint for AI factory design and operations is poised to help NVIDIA and its ecosystem of partners lead this transformation -- letting AI factory operators stay ahead of ever-evolving AI workloads, minimize downtime and maximize efficiency.

[3]

Nvidia gets industrial software firms to integrate Omniverse to accelerate physical AI

Nvidia said the big industrial software and service providers are integrating Omniverse into their platforms to accelerate industrial digitalization with physical AI. Those integrating Nvidia Omniverse include Ansys, Databricks, Dematic, Omron, SAP, Schneider Electric with ETAP, Siemens and more. Nvidia made the announcement during Jensen Huang's keynote speech during the Nvidia GTC 2025 event today in San Jose, California. New Nvidia Omniverse Blueprints connected to Nvidia Cosmos world foundation models are now available to enable robot-ready facilities and large-scale synthetic data generation for physical AI development. "Omniverse is an operating system that connects the world's physical data to the realm of physical AI," said Rev Lebaredian, vice president of Omniverse simulation technology at Nvidia, in a statement. "With Omniverse, global industrial software, data and professional services leaders are uniting industrial ecosystems and building new applications that will advance the next generation of AI for industries at unprecedented speed." New Blueprints Enable Robot-Ready Facilities and Large-Scale Synthetic Data Generation Mega, an Omniverse Blueprint for testing multi-robot fleets at scale in industrial digital twins, is now available in preview on build.nvidia.com. Also available is the Nvidia AI Blueprint for video search and summarization, powered by the Nvidia Metropolis platform, for building AI agents that monitor activity across entire facilities. Manufacturing leaders are using the blueprints to optimize their industrial operations with physical AI. In automotive manufacturing, Schaeffler and Accenture are starting to adopt Mega to test and simulate fleets of Agility Robotics Digit for material-handling automation. Hyundai Motor Group is using the blueprint to simulate Boston Dynamics Atlas robots on its assembly lines, and Mercedes-Benz is using it to simulate Apptronik's Apollo humanoid robots to optimize vehicle assembly operations. In electronics manufacturing, Pegatron is using Mega to develop physical AI-based Nvidia Metropolis video analytics agents to improve factory operations and worker safety. Foxconn is using the blueprint to simulate industrial manipulators, humanoids and mobile robots in its manufacturing facilities for the Nvidia Blackwell platform. "Foxconn is constantly exploring ways to transform our operations as we continue our journey toward building the factories of the future," said Brand Cheng, CEO of Fii, a core subsidiary of Foxconn, in a statement. "Using NVIDIA Omniverse and Mega, we're testing and training humanoids to operate in our leading factories as we advance to the next wave of physical AI." For warehouses and supply chain solutions, KION Group, Dematic and Accenture announced they are integrating Mega to advance next-generation AI-powered automation. Idealworks is integrating Mega into its fleet management software to simulate, test and optimize robotic fleets. SAP customers and partners can use Omniverse to develop their own virtual environments for warehouse management scenarios. A new Omniverse Blueprint for AI factory digital twins lets data center engineers design and simulate AI factory layouts, cooling and electrical to maximize utilization and efficiency. Cadence Reality Digital Twin Platform and Schneider Electric with ETAP are the first to integrate their simulation software into the blueprint, while Vertiv and Schneider Electric are providing Omniverse SimReady 3D models of their power and cooling units to accelerate the development of AI factory digital twins. The Nvidia Isaac GR00T Blueprint for synthetic manipulation motion generation is also now available for robotics developers, enabling large-scale synthetic data generation from Omniverse and Cosmos. The blueprint helps humanoid developers reduce data collection time from hours to minutes, fast-tracking robot development. Omniverse Physical AI Operating System Expands Across Industries Digitalization is challenging for industries grounded in the physical world. Massive amounts of digital and physical world data from legacy systems create silos. Omniverse is an operating system built on the OpenUSD framework that enables developers to unify physical-world data and applications. Ansys, Cadence, Hexagon, Omron, Rockwell Automation and Siemens are integrating Omniverse data interoperability and visualization technologies into their leading industrial software, simulation and automation solutions to accelerate product development and optimize manufacturing processes. For physical AI, Intrinsic, an Alphabet company, is enabling Omniverse workflows and Nvidia robotics foundation models to transition from digital twins to hardware deployments using Flowstate. Databricks is integrating Nvidia Omniverse with the Databricks Data Intelligence Platform, which will enable large-scale synthetic data generation for physical AI. General Motors, America's largest auto manufacturer, announced its adoption of Omniverse to enhance its factories and train platforms for operations such as material handling, transportation and precision welding. At the other end of the manufacturing life cycle, Unilever announced its adoption of Omniverse and physically accurate digital twins to streamline and optimize marketing content creation for its products. Omniverse in Every Cloud To simplify development, deployment and scale-out of OpenUSD-based applications, Nvidia Omniverse is now available as virtual desktop images on EC2 G6e instances with NVIDIA L40S GPUs in AWS Marketplace. The Microsoft Azure Marketplace now features preconfigured Omniverse instances and Omniverse Kit App Streaming on Nvidia A10 GPUs, allowing developers to easily develop and stream their custom Omniverse applications. These cloud-based Nvidia Omniverse developer tools and services are expected to be available later this year on Oracle Cloud Infrastructure compute bare-metal instances with Nvidia L40S GPUs, as well as the newly announced Nvidia RTX Pro 6000 Blackwell Server Edition on Google Cloud. OpenUSD Unifies Robotics Workflows At GTC, NVIDIA introduced the OpenUSD Asset Structure Pipeline for Robotics with Disney Research and Intrinsic. This new structure and data pipeline uses today's best practices within OpenESt to work toward unifying robotic workflows, providing a common language for all data sources.

[4]

NVIDIA Omniverse Physical AI Operating System Expands to More Industries and Partners

GTC -- NVIDIA today unveiled that leading industrial software and service providers Ansys, Databricks, Dematic, Omron, SAP, Schneider Electric with ETAP, Siemens and more are integrating the NVIDIA Omniverse™ platform into their solutions to accelerate industrial digitalization with physical AI. New NVIDIA Omniverse Blueprints connected to NVIDIA Cosmos™ world foundation models are now available to enable robot-ready facilities and large-scale synthetic data generation for physical AI development. "Omniverse is an operating system that connects the world's physical data to the realm of physical AI," said Rev Lebaredian, vice president of Omniverse and simulation technology at NVIDIA. "With Omniverse, global industrial software, data and professional services leaders are uniting industrial ecosystems and building new applications that will advance the next generation of AI for industries at unprecedented speed." New Blueprints Enable Robot-Ready Facilities and Large-Scale Synthetic Data Generation Mega, an Omniverse Blueprint for testing multi-robot fleets at scale in industrial digital twins, is now available in preview on build.nvidia.com. Also available is the NVIDIA AI Blueprint for video search and summarization, powered by the NVIDIA Metropolis platform, for building AI agents that monitor activity across entire facilities. Manufacturing leaders are using the blueprints to optimize their industrial operations with physical AI. In automotive manufacturing, Schaeffler and Accenture are starting to adopt Mega to test and simulate fleets of Agility Robotics Digit for material-handling automation. Hyundai Motor Group is using the blueprint to simulate Boston Dynamics Atlas robots on its assembly lines, and Mercedes-Benz is using it to simulate Apptronik's Apollo humanoid robots to optimize vehicle assembly operations. In electronics manufacturing, Pegatron is using Mega to develop physical AI-based NVIDIA Metropolis video analytics agents to improve factory operations and worker safety. Foxconn is using the blueprint to simulate industrial manipulators, humanoids and mobile robots in its manufacturing facilities for the NVIDIA Blackwell platform. "Foxconn is constantly exploring ways to transform our operations as we continue our journey toward building the factories of the future," said Brand Cheng, CEO of Fii, a core subsidiary of Foxconn. "Using NVIDIA Omniverse and Mega, we're testing and training humanoids to operate in our leading factories as we advance to the next wave of physical AI." For warehouses and supply chain solutions, KION Group, Dematic and Accenture announced they are integrating Mega to advance next-generation AI-powered automation. idealworks is integrating Mega into its fleet management software to simulate, test and optimize robotic fleets. SAP customers and partners can use Omniverse to develop their own virtual environments for warehouse management scenarios. A new Omniverse Blueprint for AI factory digital twins lets data center engineers design and simulate AI factory layouts, cooling and electrical to maximize utilization and efficiency. Cadence Reality Digital Twin Platform and Schneider Electric with ETAP are the first to integrate their simulation software into the blueprint, while Vertiv and Schneider Electric are providing Omniverse SimReady 3D models of their power and cooling units to accelerate the development of AI factory digital twins. The NVIDIA Isaac GR00T Blueprint for synthetic manipulation motion generation is also now available for robotics developers, enabling large-scale synthetic data generation from Omniverse and Cosmos. The blueprint helps humanoid developers reduce data collection time from hours to minutes, fast-tracking robot development. Omniverse Physical AI Operating System Expands Across Industries Digitalization is challenging for industries grounded in the physical world. Massive amounts of digital and physical world data from legacy systems create silos. Omniverse is an operating system built on the OpenUSD framework that enables developers to unify physical-world data and applications. Ansys, Cadence, Hexagon, Omron, Rockwell Automation and Siemens are integrating Omniverse data interoperability and visualization technologies into their leading industrial software, simulation and automation solutions to accelerate product development and optimize manufacturing processes. For physical AI, Intrinsic, an Alphabet company, is enabling Omniverse workflows and NVIDIA robotics foundation models to transition from digital twins to hardware deployments using Flowstate. Databricks is integrating NVIDIA Omniverse with the Databricks Data Intelligence Platform, which will enable large-scale synthetic data generation for physical AI. General Motors, America's largest auto manufacturer, announced its adoption of Omniverse to enhance its factories and train platforms for operations such as material handling, transportation and precision welding. At the other end of the manufacturing life cycle, Unilever announced its adoption of Omniverse and physically accurate digital twins to streamline and optimize marketing content creation for its products. Omniverse in Every Cloud To simplify development, deployment and scale-out of OpenUSD-based applications, NVIDIA Omniverse is now available as virtual desktop images on EC2 G6e instances with NVIDIA L40S GPUs in AWS Marketplace. The Microsoft Azure Marketplace now features preconfigured Omniverse instances and Omniverse Kit App Streaming on NVIDIA A10 GPUs, allowing developers to easily develop and stream their custom Omniverse applications. These cloud-based NVIDIA Omniverse developer tools and services are expected to be available later this year on Oracle Cloud Infrastructure compute bare-metal instances with NVIDIA L40S GPUs, as well as the newly announced NVIDIA RTX PRO™ 6000 Blackwell Server Edition on Google Cloud. OpenUSD Unifies Robotics Workflows At GTC, NVIDIA introduced the OpenUSD Asset Structure Pipeline for Robotics with Disney Research and Intrinsic. This new structure and data pipeline uses today's best practices within OpenUSD to work toward unifying robotic workflows, providing a common language for all data sources.

[5]

Nvidia expands Omniverse to simulate gigawatt AI data centers and drive robotic factories

Nvidia Omniverse provides a "metaverse" simulation platform for developers, artists and engineers where they can visualize and generate 3D models for projects. These simulations act and react with real-world physics so developers can build and test anything they can imagine. This capability enables precise digital recreation of industrial assets -- from automotive prototypes and aerospace components to complete manufacturing facilities -- with the precision needed for meaningful engineering analysis. "Omniverse is an operating system that connects the world's physical data to the realm of physical AI," said Rev Lebaredian, vice president of Omniverse and simulation technology at Nvidia. Nvidia's newly released Omniverse Blueprint for AI factory digital twins, or virtual replicas, expands these capabilities for gigawatt-scale artificial intelligence data center infrastructure. This specialized toolset allows engineers to design and simulate complete AI data center environments, encompassing critical systems like cooling infrastructure and electrical networks. Using the platform, they can design data centers all the way down to the foundation, wiring, racks, pipes, and pumps, then run them through thousands of hours of accelerated simulations. This testing can reveal operational insights, identify potential issues, and validate performance long before construction begins, thus significantly reducing costly real-world modifications. It can also simulate operations for running data centers to provide control and insights for optimization and maintenance. Schneider Electric, a leader in digital transformation for energy management, and ETAP, an industry and technology leader in power system design and operation, today unveiled a digital twin solution using the new blueprint. By creating a virtual replica of AI data centers that bring together inputs for mechanical, thermal, networking and electrical to simulate how the AI factory operates, it can predict failures, provide enhanced insights for efficiency and deliver greater opportunities for sustainability, the companies said. "This collaboration represents more than just a technological solution," said Tanuj Khandelwal, chief executive of ETAP. "We're fundamentally reimagining how data centers can be designed, managed and optimized in the AI era." Nvidia also announced Mega, an Omniverse blueprint for testing multi-robot fleets at scale in industrial digital twins. For automotive manufacturing, Scheffler and Accenture are adopting Mega to test and simulate fleets of Agility Robotics Inc.'s bipedal robot Digit for material handling and Hyundai Motor Group is using it to simulate Boston Dynamics Atlas robots in its assembly lines. For electronics, Hon Hai Technology Group, better known as Foxconn, is using Mega to simulate industrial manipulators, humanoid and mobile robots at scale in its manufacturing campuses. For physical AI, the integration of artificial intelligence into physical systems such as robots and machines, allowing them to perceive understand and interact with the real world, Intrinsic, an Alphabet Inc. company partnered with Nvidia to use Omniverse and robotics models to transition from digital twins to hardware. Databricks Inc., a global data analytics and AI company, is integrating Omniverse into its platform to enable the large-scale production of synthetic data for AI-powered robotics.

Share

Share

Copy Link

NVIDIA unveils new Omniverse Blueprints for AI factory design and multi-robot fleet testing, partnering with major industrial firms to accelerate AI-driven manufacturing and data center optimization.

NVIDIA Unveils Omniverse Blueprints for AI Factories and Industrial Robotics

NVIDIA has announced significant expansions to its Omniverse platform, introducing new blueprints aimed at revolutionizing AI factory design and industrial robotics. These developments, revealed at the NVIDIA GTC 2025 event, represent a major leap forward in the integration of physical AI with industrial processes

1

2

.AI Factory Design Blueprint

The NVIDIA Omniverse Blueprint for AI factory design and operations is a groundbreaking tool that allows engineers to design, test, and optimize gigawatt-scale AI factories using digital twins

2

. This blueprint offers several key advantages:- Real-time simulation of power, cooling, and networking systems

- Integration with leading simulation tools like Cadence Reality Digital Twin Platform and ETAP

- Ability to test and refine strategies in seconds, rather than hours

- Potential to save millions of dollars by preventing infrastructure failures and downtime

2

Mega Blueprint for Multi-Robot Fleet Testing

NVIDIA also introduced Mega, an Omniverse Blueprint for testing multi-robot fleets at scale in industrial digital twins

3

. This blueprint is being adopted by major manufacturers:- Schaeffler and Accenture are using it to simulate Agility Robotics Digit robots for material handling

- Hyundai Motor Group is simulating Boston Dynamics Atlas robots on assembly lines

- Mercedes-Benz is optimizing vehicle assembly with Apptronik's Apollo humanoid robots

3

Industrial Partnerships and Integrations

NVIDIA's Omniverse platform is being integrated by leading industrial software and service providers, including:

- Ansys, Cadence, Hexagon, Omron, Rockwell Automation, and Siemens for product development and manufacturing optimization

- Intrinsic (an Alphabet company) for transitioning from digital twins to hardware deployments

- Databricks for large-scale synthetic data generation for physical AI

4

Related Stories

Impact on Manufacturing and Data Centers

The expansion of Omniverse is set to transform various industries:

- In electronics manufacturing, Pegatron and Foxconn are using Mega to improve factory operations and simulate robotic systems

3

- General Motors is adopting Omniverse to enhance its factories and train platforms for various operations

4

- Data center engineers can now design and simulate AI factory layouts, cooling, and electrical systems to maximize efficiency

5

Cloud Availability and Future Developments

To facilitate wider adoption, NVIDIA Omniverse is now available on major cloud platforms:

- Virtual desktop images on AWS EC2 G6e instances with NVIDIA L40S GPUs

- Preconfigured instances and app streaming on Microsoft Azure Marketplace

4

NVIDIA is also working on AI-enabled operations, collaborating with companies like Vertech and Phaidra to integrate reinforcement learning AI agents into Omniverse for optimizing thermal stability and energy efficiency

2

.As AI continues to reshape the global data center landscape, with projections of $1 trillion for AI-driven upgrades, NVIDIA's Omniverse platform is positioning itself as an essential tool for the next generation of industrial AI applications

2

5

.References

Summarized by

Navi

[2]

[3]

Related Stories

NVIDIA Expands Omniverse with Generative AI for Physical AI Applications

07 Jan 2025•Technology

NVIDIA Expands Omniverse Blueprint for AI Factory Digital Twins, Accelerating Industrial AI Development

19 May 2025•Technology

NVIDIA Unveils Cosmos Reason and Advanced AI Models for Robotics and Physical AI Applications

12 Aug 2025•Technology

Recent Highlights

1

Pentagon threatens to cut Anthropic's $200M contract over AI safety restrictions in military ops

Policy and Regulation

2

ByteDance's Seedance 2.0 AI video generator triggers copyright infringement battle with Hollywood

Policy and Regulation

3

OpenAI closes in on $100 billion funding round with $850 billion valuation as spending plans shift

Business and Economy