Siemens and NVIDIA expand partnership to build AI-driven manufacturing sites launching in 2026

3 Sources

3 Sources

[1]

Siemens, NVIDIA outline roadmap for AI-driven factories at CES 2026

The first fully AI-driven, adaptive manufacturing site based on this approach is expected to launch in 2026 at Siemens Electronics Factory in Erlangen, Germany. Under the expanded partnership, NVIDIA will provide AI infrastructure, simulation libraries, models, and frameworks, while Siemens will deploy hundreds of industrial AI experts alongside its hardware and software portfolio. Together, the companies aim to create AI-native workflows that accelerate innovation while reducing cost, risk, and commissioning time. Roland Busch, President and CEO of Siemens AG, described the effort as a shift in how physical systems are designed and operated. "Together, we are building the Industrial AI operating system - redefining how the physical world is designed, built, and run - to scale AI and create real-world impact," Busch said. At the core of the initiative is the idea of factories that continuously analyze their own digital twins. Using an AI Brain powered by software-defined automation, industrial operations software, and NVIDIA Omniverse libraries, facilities can test process changes virtually before applying them in the real world.

[2]

Siemens, NVIDIA deepen collaboration on industrial AI, digital twins (NVDA:NASDAQ)

Siemens (SIEGY) (SMAWF) and NVIDIA (NVDA) said at CES 2026 that they are expanding their partnership to develop what the companies describe as an industrial AI operating system spanning product design, manufacturing, operations and supply chains. Under the expanded agreement, NVIDIA ( The partnership aims to embed AI more deeply in industrial workflows, accelerating the use of digital twins, simulation, and automation across factories and supply networks. Manufacturers could see faster, larger, and more frequent simulations, reduced design cycle times, and improvements in manufacturing outcomes through AI-enhanced software and GPU acceleration. Standardized designs are intended to improve energy efficiency and operational resilience for large-scale AI infrastructure, addressing power, cooling, automation, and grid integration challenges.

[3]

Nvidia, Siemens Expand Partnership to Develop Fully AI-Driven Manufacturing Sites

Nvidia and Siemens are expanding their industrial and physical artificial-intelligence partnership, aiming to build the first fully AI-driven, adaptive manufacturing sites this year. The companies said Tuesday at the Consumer Electronics Show 2026 in Las Vegas that they will leverage Nvidia's AI infrastructure and Siemen's industrial AI experts, hardware and software, including its digital twins technology, to build AI solutions across full industrial lifecycles. They are using Siemens Electronics Factory in Erlangen, Germany, as a first blueprint for the project, expected to start this year. Siemens also will complete GPU acceleration across its simulation portfolio and expand support for Nvidia libraries and models, and both companies will advance generative simulation work using Nvidia PhysicsNeMo as part of the expansion, they said. "Together, we are building the Industrial AI operating system - redefining how the physical world is designed, built, and run - to scale AI and create real-world impact," Siemens Chief Executive Roland Busch said. The companies said several customers are already evaluating these capabilities, including Foxconn, HD Hyundai, KION Group, and PepsiCo, which said on Tuesday it was partnering with the two tech firms to modernize its physical production processes. Siemens and Nvidia said they hope to develop a repeatable blueprint for AI-powered factories to accelerate deployment. They also said they are implementing new technologies in their own systems to create proof points of value and scalability before scaling them across various sectors. Write to Elias Schisgall at [email protected]

Share

Share

Copy Link

Siemens and NVIDIA announced an expanded partnership at CES 2026 to develop an industrial AI operating system for fully AI-driven, adaptive manufacturing facilities. The first site will launch in 2026 at Siemens Electronics Factory in Erlangen, Germany, with major companies like Foxconn, PepsiCo, and HD Hyundai already evaluating the technology.

Siemens NVIDIA Partnership Expands to Transform Industrial Operations

Siemens and NVIDIA unveiled an ambitious expansion of their collaboration at CES 2026 in Las Vegas, setting the stage for what they call an industrial AI operating system that will reshape product design, manufacturing, operations, and supply chains

1

2

. The Siemens NVIDIA partnership aims to integrate AI into industrial workflows at an unprecedented scale, moving beyond incremental improvements to fundamentally alter how physical systems function. Roland Busch, President and CEO of Siemens AG, characterized the initiative as building the foundation to "scale AI and create real-world impact" across industries3

.

Source: Interesting Engineering

First AI-Driven Manufacturing Site Targets 2026 Launch

The first fully AI-driven, adaptive manufacturing facilities based on this collaboration will debut in 2026 at Siemens Electronics Factory in Erlangen, Germany

1

3

. This site will serve as a blueprint for AI-driven adaptive manufacturing facilities that can be replicated across sectors. Under the expanded agreement, NVIDIA will provide AI infrastructure, simulation libraries, models, and frameworks, while Siemens will deploy hundreds of industrial AI experts alongside its extensive hardware and software portfolio1

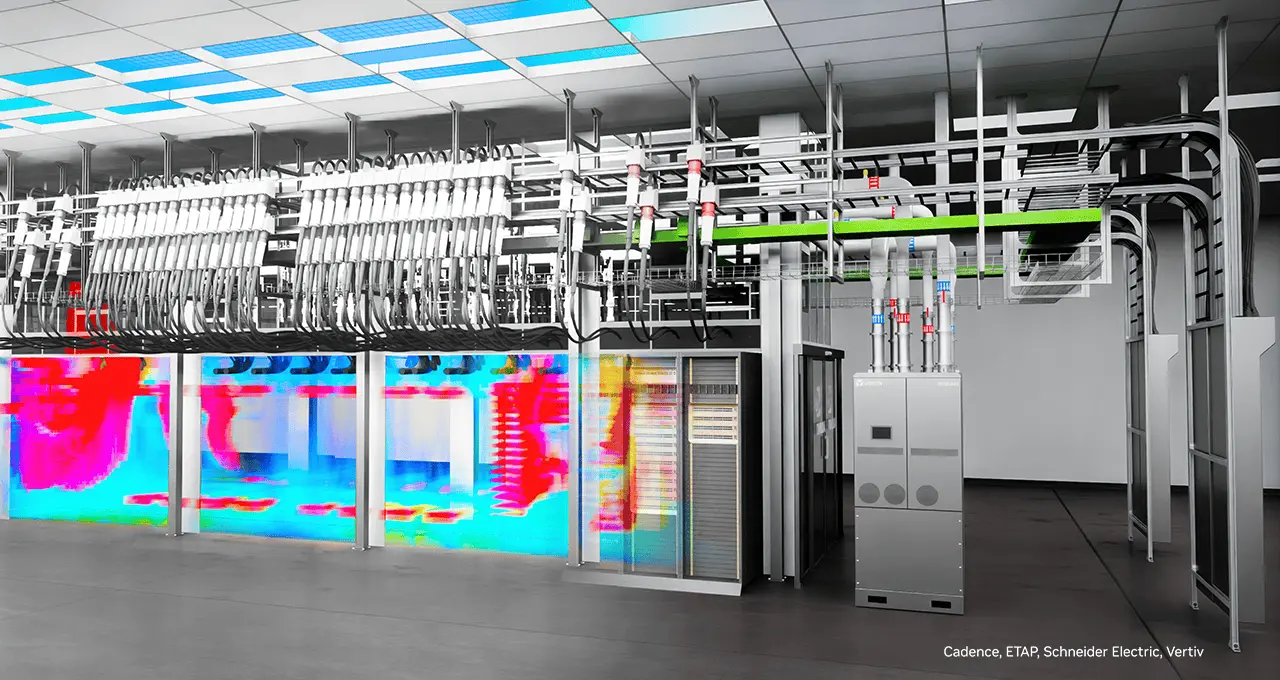

. The companies are implementing these technologies in their own systems first to create proof points of value and scalability before rolling them out to customers.Digital Twin Technology Powers Continuous Factory Optimization

At the heart of this industrial AI approach lies the concept of factories that continuously analyze their own digital twins. Using an AI Brain powered by software-defined automation, industrial operations software, and NVIDIA Omniverse libraries, facilities can test process changes virtually before applying them in the real world

1

. Digital twin technology enables manufacturers to run faster, larger, and more frequent simulations, reducing design cycle times while improving manufacturing outcomes2

. Siemens will complete GPU acceleration across its simulation portfolio and expand support for NVIDIA libraries and models, with both companies advancing generative simulation work using NVIDIA PhysicsNeMo3

.Major Manufacturers Already Evaluating AI-Powered Factories

Several industry leaders are already assessing these capabilities for their operations. Foxconn, HD Hyundai, KION Group, and PepsiCo are among the companies evaluating the technology

3

. PepsiCo specifically announced on Tuesday that it was partnering with both firms to modernize its physical production processes. The companies aim to create AI-native workflows that accelerate innovation while reducing cost, risk, and commissioning time1

. This repeatable blueprint for AI-powered factories could enable rapid deployment across manufacturing sectors, from electronics to food and beverage production.Energy Efficiency and Operational Resilience Take Center Stage

The partnership addresses critical infrastructure challenges that come with large-scale AI deployment in industrial settings. Standardized designs are intended to improve energy efficiency and operational resilience for AI infrastructure, tackling power, cooling, automation, and grid integration challenges

2

. As manufacturers face pressure to reduce environmental impact while maintaining competitiveness, the ability to optimize manufacturing outcomes through AI software and GPU acceleration becomes increasingly valuable. The collaboration positions both companies to shape how industries balance productivity demands with sustainability goals, particularly as AI adoption accelerates across global supply networks.🟡 untrained=🟡Siemens NVIDIA Partnership Expands to Transform Industrial OperationsSiemens and NVIDIA unveiled an ambitious expansion of their collaboration at CES 2026 in Las Vegas, setting the stage for what they call an industrial AI operating system that will reshape product design, manufacturing, operations, and supply chains

1

2

. The Siemens NVIDIA partnership aims to integrate AI into industrial workflows at an unprecedented scale, moving beyond incremental improvements to fundamentally alter how physical systems function. Roland Busch, President and CEO of Siemens AG, characterized the initiative as building the foundation to "scale AI and create real-world impact" across industries3

.

Source: Interesting Engineering

First AI-Driven Manufacturing Site Targets 2026 Launch

The first fully AI-driven, adaptive manufacturing facilities based on this collaboration will debut in 2026 at Siemens Electronics Factory in Erlangen, Germany

1

3

. This site will serve as a blueprint for AI-driven adaptive manufacturing facilities that can be replicated across sectors. Under the expanded agreement, NVIDIA will provide AI infrastructure, simulation libraries, models, and frameworks, while Siemens will deploy hundreds of industrial AI experts alongside its extensive hardware and software portfolio1

. The companies are implementing these technologies in their own systems first to create proof points of value and scalability before rolling them out to customers.Related Stories

Digital Twin Technology Powers Continuous Factory Optimization

At the heart of this industrial AI approach lies the concept of factories that continuously analyze their own digital twins. Using an AI Brain powered by software-defined automation, industrial operations software, and NVIDIA Omniverse libraries, facilities can test process changes virtually before applying them in the real world

1

. Digital twin technology enables manufacturers to run faster, larger, and more frequent simulations, reducing design cycle times while improving manufacturing outcomes2

. Siemens will complete GPU acceleration across its simulation portfolio and expand support for NVIDIA libraries and models, with both companies advancing generative simulation work using NVIDIA PhysicsNeMo3

.Major Manufacturers Already Evaluating AI-Powered Factories

Several industry leaders are already assessing these capabilities for their operations. Foxconn, HD Hyundai, KION Group, and PepsiCo are among the companies evaluating the technology

3

. PepsiCo specifically announced on Tuesday that it was partnering with both firms to modernize its physical production processes. The companies aim to create AI-native workflows that accelerate innovation while reducing cost, risk, and commissioning time1

. This repeatable blueprint for AI-powered factories could enable rapid deployment across manufacturing sectors, from electronics to food and beverage production.Energy Efficiency and Operational Resilience Take Center Stage

The partnership addresses critical infrastructure challenges that come with large-scale AI deployment in industrial settings. Standardized designs are intended to improve energy efficiency and operational resilience for AI infrastructure, tackling power, cooling, automation, and grid integration challenges

2

. As manufacturers face pressure to reduce environmental impact while maintaining competitiveness, the ability to optimize manufacturing outcomes through AI software and GPU acceleration becomes increasingly valuable. The collaboration positions both companies to shape how industries balance productivity demands with sustainability goals, particularly as AI adoption accelerates across global supply networks.References

Summarized by

Navi

[1]

Related Stories

NVIDIA Expands Omniverse Blueprint for AI Factory Digital Twins, Accelerating Industrial AI Development

19 May 2025•Technology

PepsiCo partners with Nvidia and Siemens on AI collaboration to transform manufacturing operations

07 Jan 2026•Technology

NVIDIA and Deutsche Telekom Partner to Build World's First Industrial AI Cloud in Germany

11 Jun 2025•Technology

Recent Highlights

1

Pentagon threatens to cut Anthropic's $200M contract over AI safety restrictions in military ops

Policy and Regulation

2

ByteDance's Seedance 2.0 AI video generator triggers copyright infringement battle with Hollywood

Policy and Regulation

3

OpenAI closes in on $100 billion funding round with $850 billion valuation as spending plans shift

Business and Economy