NVIDIA Unveils 'Mega' Omniverse Blueprint for Revolutionizing Warehouse Robotics

5 Sources

5 Sources

[1]

NVIDIA Unveils AI-Powered Digital Twin Tech For Warehouse Operations - NVIDIA (NASDAQ:NVDA)

Mega enables testing of AI-driven robots in virtual environments. NVIDIA Corp NVDA introduced a new AI-powered digital twin solution at CES 2025, aimed at transforming the operations of warehouses and factories. Known as the "Mega Omniverse Blueprint," this tool allows enterprises to test robots' decision-making processes, sensor data, and route planning, all within a digital twin of their facility. This is expected to help businesses improve operational efficiency by simulating environments where robots can interact, learn, and optimize their tasks. The solution is built on NVIDIA's advanced computing technologies, including Isaac and Omniverse, which power the robots and other automated systems. The announcement comes as part of an ongoing effort to bring software-defined solutions to physical industrial sectors, which have long struggled to modernize their operations. KION Group, a supply chain solutions company, has partnered with Accenture Plc ACN and NVIDIA to be the first to adopt Mega in order to enhance operations across retail, logistics, and consumer goods. Also Read: OpenAI CEO Sam Altman Says Company Losing Money On ChatGPT Pro Plan During a demonstration at CES, Jensen Huang, CEO of NVIDIA, showcased how this new tool can help enterprises navigate complex decision-making processes, improving productivity and reducing operational friction. The effort aims to make warehouses smarter and more adaptable by incorporating AI-driven solutions. For instance, KION can now use the Omniverse digital twin to simulate warehouse conditions, creating highly detailed virtual environments for testing robotic systems. These robots can independently carry out tasks such as moving loads and making decisions based on real-time feedback within the simulation. In addition, Accenture is adopting the Mega blueprint as part of its AI Refinery for Simulation and Robotics initiative to deliver services that improve the design and efficiency of manufacturing and logistics systems. Huang said that self-driving vehicles would become "the first multi-trillion dollar robotics industry," sparking debate about the future of transportation. In his keynote address at CES, Huang also unveiled the latest GeForce RTX 5000 graphics card series, which includes the $1,999 RTX 5090, $999 RTX 5080, $749 RTX 5070 Ti, and $549 RTX 5070. Price Action: NVDA shares traded lower by 5.80% to $140.77 at the last check on Tuesday. Read Next: Nvidia Stock Drops After Huang's CES Keynote: Analysts Dub It 'End-To-End AI Shop' Image via Shutterstock NVDANVIDIA Corp$140.23-6.16%Overview Rating:Good75%Technicals Analysis1000100Financials Analysis600100WatchlistOverviewACNAccenture PLC$356.391.44% This content was partially produced with the help of AI tools and was reviewed and published by Benzinga editors. Market News and Data brought to you by Benzinga APIs

[2]

Nvidia unveils Mega Omniverse blueprint for building industrial robot fleet digital twins

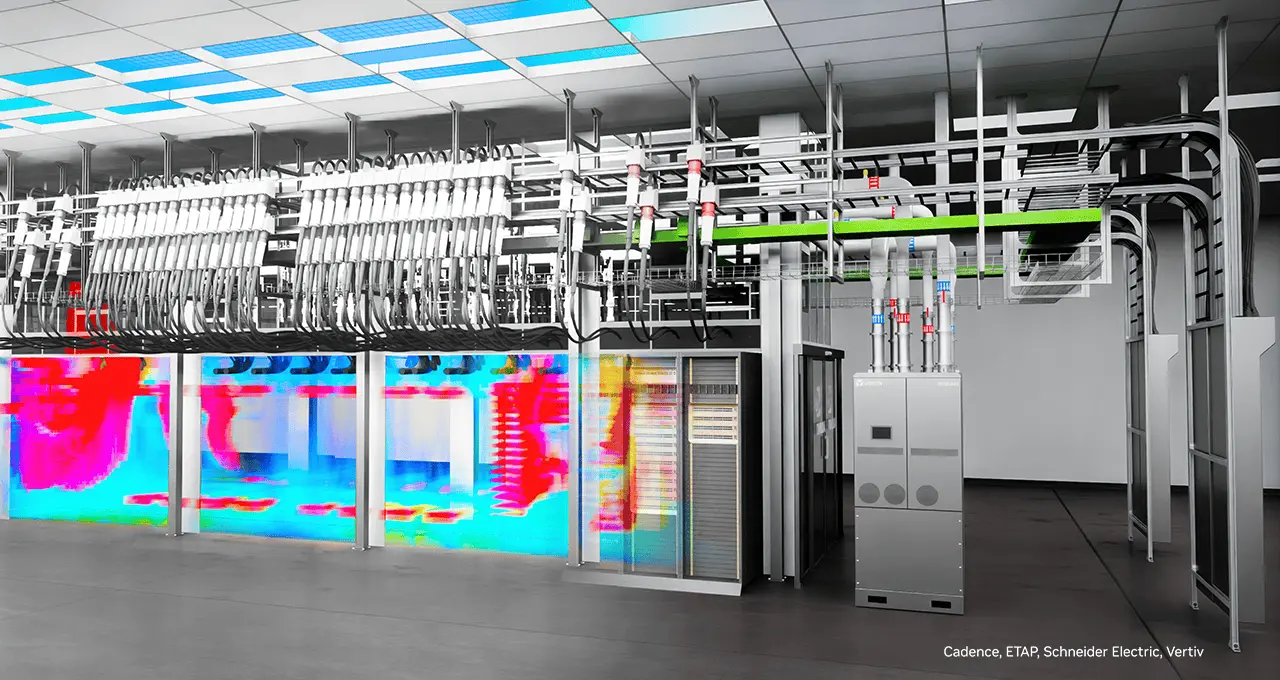

The new framework enables next era of industrial AI and robot simulation through software-defined testing and optimization to factories and warehouses, the company said. According to Gartner, the worldwide end-user spending on all IT products for 2024 was $5 trillion. This industry is built on a computing fabric of electrons, is fully software-defined, accelerated -- and now generative AI-enabled. While huge, it's a fraction of the larger physical industrial market that relies on the movement of atoms. "In the future, every factory will have a digital twin," Huang said. Today's 10 million factories, nearly 200,000 warehouses and 40 million miles of highways form the "computing" fabric of our physical world. But that vast network of production facilities and distribution centers is still laboriously and manually designed, operated and optimized. In warehousing and distribution, operators face highly complex decision optimization problems -- matrices of variables and interdependencies across human workers, robotic and agentic systems and equipment. Unlike the IT industry, the physical industrial market is still waiting for its own software-defined moment. That moment is coming, Nvidia said. The company today at CES announced "Mega," an Omniverse Blueprint for developing, testing and optimizing physical AI and robot fleets at scale in a digital twin before deployment into real-world facilities. Advanced warehouses and factories use fleets of hundreds of autonomous mobile robots, robotic arm manipulators and humanoids working alongside people. With implementations of increasingly complex systems of sensor and robot autonomy, it requires coordinated training in simulation to optimize operations, help ensure safety and avoid disruptions. Mega offers enterprises a reference architecture of Nvidia accelerated computing, AI, Nvidia Isaac and Nvidia Omniverse technologies to develop and test digital twins for testing AI-powered robot brains that drive robots, video analytics AI agents, equipment and more for handling enormous complexity and scale. The new framework brings software-defined capabilities to physical facilities, enabling continuous development, testing, optimization and deployment. Developing AI Brains With World Simulator for Autonomous Orchestration With Mega-driven digital twins, including a world simulator that coordinates all robot activities and sensor data, enterprises can continuously update facility robot brains for intelligent routes and tasks for operational efficiencies. The blueprint uses Omniverse Cloud Sensor RTX APIs that enable robotics developers to render sensor data from any type of intelligent machine in the factory, simultaneously, for high-fidelity large-scale sensor simulation. This allows robots to be tested in an infinite number of scenarios within the digital twin, using synthetic data in a software-in-the-loop pipeline with Nvidia Isaac ROS. Supply chain solutions company Kion Group is collaborating with Accenture and Nvidia as the first to adopt Mega for optimizing operations in retail, consumer packaged goods, parcel services and more. Huang offered a glimpse into the future of this collaboration on stage at CES, demonstrating how enterprises can navigate a complex web of decisions using the Mega Omniverse Blueprint. "At Kion, we leverage AI-driven solutions as an integral part of our strategy to optimize our customers' supply chains and increase their productivity," said Rob Smith, CEO of Kion Group, in a statement. "With Nvidia's AI leadership and Accenture's expertise in digital technologies, we are reinventing warehouse automation. Bringing these strong partners together, we are creating a vision for future warehouses that are part of a smart agile system, evolve with the world around them and can handle nearly any supply chain challenge." Creating Operational Efficiencies With Mega Omniverse Blueprint Creating operational efficiencies, Kion and Accenture are embracing the Mega Omniverse Blueprint to build next-generation supply chains for Kion and its customers. Kion can capture and digitalize a warehouse digital twin in Omniverse by using computer-aided design files, video, lidar, image and AI-generated data. Kion uses the Omniverse digital twin as a virtual training and testing environment for its industrial AI's robot brains, powered by Nvidia Isaac, tapping into smart cameras, forklifts, robotic equipment and digital humans. Integrating the Omniverse digital twin, Kion's warehouse management software can create and assign missions for robot brains, like moving a load from one place to another. These simulated robots can carry out tasks by perceiving and reasoning in environments, and they're capable of planning next motions and then taking actions that are simulated in the digital twin. The robot brains perceive the results deciding the next action, and this cycle continues with Mega precisely tracking the state and position of all the assets in the digital twin. Delivering Services With Mega for Facilities Everywhere Accenture, global leader in professional services, is adopting Mega as part of its AI Refinery for Simulation and Robotics, built on NVIDIA AI and Omniverse, to help organizations use AI simulation to reinvent factory and warehouse design and ongoing operations. With the blueprint, Accenture is delivering new services - including Custom Robotics and Manufacturing Foundation Model Training and Finetuning; Intelligent Humanoid Robotics; and AI-Powered Industrial Manufacturing and Logistics Simulation and Optimization -- to expand the power of physical AI and simulation to the world's factories and warehouse operators. Now, for example, an organization can explore numerous options for their warehouse before choosing and implementing the best one. "As organizations enter the age of industrial AI, we are helping them use AI-powered simulation and autonomous robots to reinvent the process of designing new facilities and optimizing existing operations," said Julie Sweet, chair and CEO, Accenture, in a statement. "Our collaboration with Nvidia and KION will help our clients plan their operations in digital twins, where they can run hundreds of options and quickly select the best for current or changing market conditions, such as seasonal market demand or workforce availability. This represents a new frontier of value for our clients to achieve using technology, data and AI."

[3]

Nvidia unveils a fleet manager for warehouse robots

KION Group has already successfully piloted the Mega blueprint Nvidia is preparing for the rise of robots with a new fleet manager designed to help companies manage their digital workforce more easily. In an announcement, director of product and technical marketing for Nvidia Omniverse Madison Huang stated that "the physical industrial market is still waiting for its own software-defined moment," and we know Nvidia is betting big on robotics. At a tech conference late last year, VP of Omniverse and Simulation Technology Rev Lebaredian declared that humanoid AI-powered robots are destined for businesses, and eventually homes, on a global scale. If there was ever a time for Nvidia to lay the foundations for a robotic future, it's now. The announcement of a new tool designed to build industrial robot fleet digital twins comes as Nvidia launches a series of AI Blueprints to help customers build agentic AI applications. Together with partner blueprints, Nvidia launched a series of its own, including four Omniverse blueprints to help with digital twinning. The company envisions this one in particular - Mega - aiding in the development, testing and optimization of physical AI and robot fleets at scale in a digital twin so that they can be deployed into real-world facilities. Huang added that the increasing complexity of sensors and robot autonomy has made it more challenging to safely deploy such technologies without disruption, hence the plans to help create digital twins of environments and hardware. The Director explained how Mega works: "With Mega-driven digital twins, including a world simulator that coordinates all robot activities and sensor data, enterprises can continuously update facility robot brains for intelligent routes and tasks for operational efficiencies." Supply chain solutions company KION Group, an early tester of Nvidia's Mega blueprint, noted how it can "capture and digitalize a warehouse digital twin in Omniverse by using computer-aided design files, video, lidar, image and AI-generated data." CEO Rob Smith added: "We are reinventing warehouse automation."

[4]

NVIDIA Unveils 'Mega' Omniverse Blueprint for Building Industrial Robot Fleet Digital Twins

New framework enables next era of industrial AI and robot simulation through software-defined testing and optimization to factories and warehouses. According to Gartner, the worldwide end-user spending on all IT products for 2024 was $5 trillion. This industry is built on a computing fabric of electrons, is fully software-defined, accelerated -- and now generative AI-enabled. While huge, it's a fraction of the larger physical industrial market that relies on the movement of atoms. Today's 10 million factories, nearly 200,000 warehouses and 40 million miles of highways form the "computing" fabric of our physical world. But that vast network of production facilities and distribution centers is still laboriously and manually designed, operated and optimized. In warehousing and distribution, operators face highly complex decision optimization problems -- matrices of variables and interdependencies across human workers, robotic and agentic systems and equipment. Unlike the IT industry, the physical industrial market is still waiting for its own software-defined moment. That moment is coming. NVIDIA today at CES announced "Mega," an Omniverse Blueprint for developing, testing and optimizing physical AI and robot fleets at scale in a digital twin before deployment into real-world facilities. Advanced warehouses and factories use fleets of hundreds of autonomous mobile robots, robotic arm manipulators and humanoids working alongside people. With implementations of increasingly complex systems of sensor and robot autonomy, it requires coordinated training in simulation to optimize operations, help ensure safety and avoid disruptions. Mega offers enterprises a reference architecture of NVIDIA accelerated computing, AI, NVIDIA Isaac and NVIDIA Omniverse technologies to develop and test digital twins for testing AI-powered robot brains that drive robots, video analytics AI agents, equipment and more for handling enormous complexity and scale. The new framework brings software-defined capabilities to physical facilities, enabling continuous development, testing, optimization and deployment. Developing AI Brains With World Simulator for Autonomous Orchestration With Mega-driven digital twins, including a world simulator that coordinates all robot activities and sensor data, enterprises can continuously update facility robot brains for intelligent routes and tasks for operational efficiencies. The blueprint uses Omniverse Cloud Sensor RTX APIs that enable robotics developers to render sensor data from any type of intelligent machine in the factory, simultaneously, for high-fidelity large-scale sensor simulation. This allows robots to be tested in an infinite number of scenarios within the digital twin, using synthetic data in a software-in-the-loop pipeline with NVIDIA Isaac ROS. Supply chain solutions company KION Group is collaborating with Accenture and NVIDIA as the first to adopt Mega for optimizing operations in retail, consumer packaged goods, parcel services and more. Jensen Huang, founder and CEO of NVIDIA, offered a glimpse into the future of this collaboration on stage at CES, demonstrating how enterprises can navigate a complex web of decisions using the Mega Omniverse Blueprint. "At KION, we leverage AI-driven solutions as an integral part of our strategy to optimize our customers' supply chains and increase their productivity," said Rob Smith, CEO of KION GROUP AG. "With NVIDIA's AI leadership and Accenture's expertise in digital technologies, we are reinventing warehouse automation. Bringing these strong partners together, we are creating a vision for future warehouses that are part of a smart agile system, evolve with the world around them and can handle nearly any supply chain challenge." Creating Operational Efficiencies With Mega Omniverse Blueprint Creating operational efficiencies, KION and Accenture are embracing the Mega Omniverse Blueprint to build next-generation supply chains for KION and its customers. KION can capture and digitalize a warehouse digital twin in Omniverse by using computer-aided design files, video, lidar, image and AI-generated data. KION uses the Omniverse digital twin as a virtual training and testing environment for its industrial AI's robot brains, powered by NVIDIA Isaac, tapping into smart cameras, forklifts, robotic equipment and digital humans. Integrating the Omniverse digital twin, KION's warehouse management software can create and assign missions for robot brains, like moving a load from one place to another. These simulated robots can carry out tasks by perceiving and reasoning in environments, and they're capable of planning next motions and then taking actions that are simulated in the digital twin. The robot brains perceive the results deciding the next action, and this cycle continues with Mega precisely tracking the state and position of all the assets in the digital twin. Delivering Services With Mega for Facilities Everywhere Accenture, global leader in professional services, is adopting Mega as part of its AI Refinery for Simulation and Robotics, built on NVIDIA AI and Omniverse, to help organizations use AI simulation to reinvent factory and warehouse design and ongoing operations. With the blueprint, Accenture is delivering new services -- including Custom Robotics and Manufacturing Foundation Model Training and Finetuning; Intelligent Humanoid Robotics; and AI-Powered Industrial Manufacturing and Logistics Simulation and Optimization -- to expand the power of physical AI and simulation to the world's factories and warehouse operators. Now, for example, an organization can explore numerous options for their warehouse before choosing and implementing the best one. "As organizations enter the age of industrial AI, we are helping them use AI-powered simulation and autonomous robots to reinvent the process of designing new facilities and optimizing existing operations," said Julie Sweet, chair and CEO of Accenture. "Our collaboration with NVIDIA and KION will help our clients plan their operations in digital twins, where they can run hundreds of options and quickly select the best for current or changing market conditions, such as seasonal market demand or workforce availability. This represents a new frontier of value for our clients to achieve using technology, data and AI."

[5]

Nvidia details Mega, a fleet manager for warehouse robots | TechCrunch

Nvidia continues its expansion into robotics software with Mega an Omniverse Blueprint designed specifically for robotic fleet management at scale. The offering, announced at CES Monday, specifically targets warehouses, a space that saw massive robotics adoption during the pandemic. Even so, most still lack significant automation. Companies like Locus Robotics have made significant headway in this world, with fleets of autonomous mobile robotics. Ultimately, however, the future of warehouse automation isn't a single company or solution. It's an ecosystem wherein robotics of various form factors can work in tandem to get the job done. That includes AMRs, robotic arms, autonomous forklifts, and, possibly, humanoids. Efficient, robot agnostic fleet management remains a holy grail for this world, and Nvidia is as well positioned as anyone to address the need. "Mega offers enterprises a reference architecture of Nvidia accelerated computing, AI, Nvidia Isaac and Nvidia Omniverse technologies to develop and test digital twins for testing AI-powered robot brains that drive robots, video analytics AI agents, equipment and more for handling enormous complexity and scale," the chipmaker notes. "The new framework brings software-defined capabilities to physical facilities, enabling continuous development, testing, optimization, and deployment." Mega develops digital twins of robotic systems and settings, in a bid to determine optimal routes and workflows for robotics systems. German supply chain firm, Kion Group, is the first to official adopt Mega for its workflows.

Share

Share

Copy Link

NVIDIA introduces Mega, an AI-powered digital twin solution for optimizing warehouse operations through advanced simulation and testing of robotic systems.

NVIDIA Introduces Mega Omniverse Blueprint

NVIDIA has unveiled its latest innovation in AI and robotics technology at CES 2025: the Mega Omniverse Blueprint. This groundbreaking solution aims to transform warehouse and factory operations by enabling the development, testing, and optimization of AI-powered robot fleets within digital twin environments

1

2

.Revolutionizing Warehouse Automation

The Mega Omniverse Blueprint offers a comprehensive framework for creating digital replicas of physical facilities. This allows companies to simulate and refine complex robotic systems before real-world deployment, potentially saving time and resources while improving operational efficiency

3

.Key features of the Mega blueprint include:

- A world simulator coordinating robot activities and sensor data

- Omniverse Cloud Sensor RTX APIs for high-fidelity sensor simulation

- Integration with NVIDIA Isaac ROS for software-in-the-loop testing

- Capability to handle fleets of autonomous mobile robots, robotic arms, and even humanoid robots

2

4

Industry Collaboration and Adoption

KION Group, a leading supply chain solutions provider, has partnered with Accenture and NVIDIA to be the first adopter of the Mega blueprint. This collaboration aims to optimize operations across retail, logistics, and consumer goods sectors

1

5

.Rob Smith, CEO of KION Group, stated, "We are reinventing warehouse automation. Bringing these strong partners together, we are creating a vision for future warehouses that are part of a smart agile system, evolve with the world around them and can handle nearly any supply chain challenge."

2

Expanding the Reach of AI in Physical Industries

NVIDIA's Mega blueprint is part of a larger initiative to bring software-defined solutions to physical industrial sectors. The company recognizes that while the IT industry has fully embraced software-defined and AI-enabled systems, the larger physical industrial market is still awaiting its transformative moment

2

4

.Jensen Huang, NVIDIA's CEO, demonstrated at CES how the Mega Omniverse Blueprint can help enterprises navigate complex decision-making processes in warehouse operations

1

.Related Stories

Accenture's Adoption and Service Offerings

Accenture, a global leader in professional services, is incorporating the Mega blueprint into its AI Refinery for Simulation and Robotics. This integration will enable Accenture to offer new services, including:

- Custom Robotics and Manufacturing Foundation Model Training

- Intelligent Humanoid Robotics

- AI-Powered Industrial Manufacturing and Logistics Simulation and Optimization

2

4

These services aim to expand the power of physical AI and simulation to factories and warehouse operators worldwide, allowing organizations to explore numerous operational scenarios before implementation

2

.The Future of Warehouse Automation

As the complexity of warehouse automation increases, with hundreds of autonomous mobile robots, robotic arm manipulators, and humanoids working alongside human workers, the need for coordinated training and simulation becomes crucial

3

5

.NVIDIA's Mega Omniverse Blueprint represents a significant step towards creating more efficient, adaptable, and intelligent warehouse systems. By enabling continuous development, testing, and optimization in a virtual environment, it paves the way for a new era of industrial AI and robotics

1

2

4

.References

Summarized by

Navi

[1]

[2]

[3]

[4]

Related Stories

NVIDIA Expands Omniverse Platform to Revolutionize AI Factory Design and Industrial Robotics

19 Mar 2025•Technology

NVIDIA Unveils Cosmos Reason and Advanced AI Models for Robotics and Physical AI Applications

12 Aug 2025•Technology

NVIDIA Expands Omniverse with Generative AI for Physical AI Applications

07 Jan 2025•Technology

Recent Highlights

1

Pentagon threatens Anthropic with Defense Production Act over AI military use restrictions

Policy and Regulation

2

Google Gemini 3.1 Pro doubles reasoning score, beats rivals in key AI benchmarks

Technology

3

Anthropic accuses Chinese AI labs of stealing Claude through 24,000 fake accounts

Policy and Regulation