Tesla Eyes Massive Chip Manufacturing Plant as Musk Considers Intel Partnership for AI Ambitions

14 Sources

14 Sources

[1]

Elon Musk says Tesla needs to build 'gigantic chip fab' to meet AI and robotics needs

Tesla CEO Elon Musk attends the Saudi-U.S. Investment Forum, in Riyadh, Saudi Arabia, May 13, 2025. Tesla CEO Elon Musk says the company will likely need to build a "gigantic" semiconductor fabrication plant to keep up with its artificial intelligence and robotics ambitions. "One of the things I'm trying to figure out is -- how do we make enough chips?" Musk said at Tesla's annual shareholders meeting Thursday. Tesla currently relies on contract chipmakers Taiwan Semiconductor Manufacturing Company and Samsung Electronics to produce its chip designs and Musk said he was also considering working with Intel. "But even when we extrapolate the best-case scenario for chip production from our suppliers, it's still not enough," he said. Tesla would probably need to build a "gigantic" chip fab, which Musk described as a "Tesla terra fab." "I can't see any other way to get to the volume of chips that we're looking for." Microchips are the brains powering almost all modern technologies, from smartphones and cars to robotics. Demand has surged amid the AI boom. Tech giants, including Tesla, have been clamoring for more supply from chipmakers like TSMC -- the world's largest and most advanced chipmaker. According to Musk, Tesla's potential fab's initial capacity could reach 100,000 wafer starts per month and eventually scale up to 1 million. In the semiconductor industry, wafer starts per month is a measure of how many new chips a fab produces each month. For comparison, TSMC says its annual wafer production capacity reached 17 million in 2024, or around 1.42 million wafer starts per month. Musk's statements underscore Tesla's shift into AI and robotics -- industries the CEO sees as the future of the global economy. "With AI and robotics, you can actually increase the global economy by a factor of 10, or maybe 100. There's not, like, an obvious limit," Musk said at the shareholder meeting.

[2]

Elon Musk says Tesla could build a gigantic chip fab and work with Intel to meet demand

Serving tech enthusiasts for over 25 years. TechSpot means tech analysis and advice you can trust. What just happened? Fresh from being awarded his $1 trillion pay package by Tesla, Elon Musk has announced that the EV giant will probably have to build "a gigantic chip fab" to ensure its AI and robotic ambitions are fulfilled. Musk also said he was considering working with Intel to help meet chip demand. Speaking at the annual shareholders meeting this week, Musk said, "One of the things I'm trying to figure out is - how do we make enough chips?" "You know, maybe we'll, we'll do something with Intel," he added. "We haven't signed any deal, but it's probably worth having discussions with Intel." Tesla currently relies on TSMC and Samsung as its contract chipmakers for the hardware powering its next-gen full-self-driving systems. The automaker signed a $16.5 billion deal with Samsung earlier this year for its future A16 chip to be produced at the Texas fab. It now seems Intel could be added as another chip-building partner. A deal with Intel would give its foundry business a boost. Reports in August claimed its 18A process has been experiencing low yields and quality issues, but since then we've heard that it could begin manufacturing x86 chips for AMD, and reports suggest it has signed Microsoft as a major client for 18A. Intel's share price jumped 2.2% following Musk's comments, while Tesla's shares were up 4% in after-hours trading. Intel's year-to-date share price Musk said this week that Tesla is finalizing the design of its A15 chip, which will apparently see a 40x improvement compared to the current A14. A small number of A15 units will be produced in 2026, with high-volume production only possible in 2027. A16, meanwhile, is predicted to double the performance metrics of its predecessor and go into volume production in 2028. Musk added that it would be inexpensive, power-efficient, and optimized for Tesla software. He claimed it would probably consume about a third of the power used by Nvidia's Blackwell chip, but cost 10% less to make. "But even when we extrapolate the best-case scenario for chip production from our suppliers, it's still not enough," Musk warned. As such, Tesla will probably need to build a "gigantic" chip fab, which Musk described as a "Tesla terra fab." "I can't see any other way to get to the volume of chips that we're looking for," he said. The CEO claimed the Tesla fab would have an initial capacity of 100,000 wafer starts per month and eventually scale to 1 million. For comparison, the world's largest contract chipmaker, TSMC, has a capacity of around 1.42 million per month.

[3]

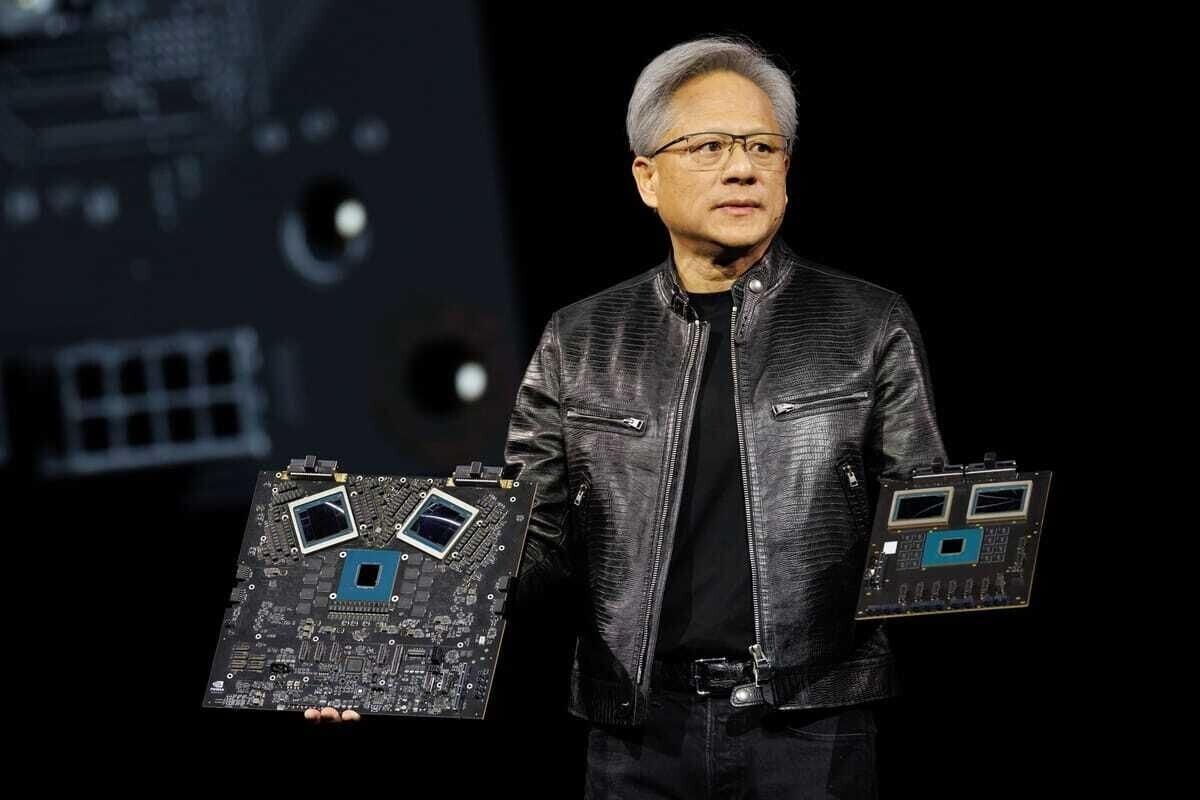

NVIDIA CEO bucks Elon Musk's plans to build chip fab, says what TSMC does is 'extremely hard'

TL;DR: NVIDIA CEO Jensen Huang praised TSMC's expertise while urging a 50% boost in 3nm chip production to meet demand for Blackwell AI GPUs. He emphasized the complexity of advanced semiconductor manufacturing, highlighting that Elon Musk's plan for a massive Tesla TeraFab faces significant engineering challenges. NVIDIA CEO Jensen Huang is enjoying the sights, the food, and the relationships in Taiwan with key suppliers, with a huge focus on TSMC, where he told local reporters that Elon Musk's ambitious plans of building a semiconductor fab isn't easy, and that doing what TSMC does for a living is "extremely hard". Jensen has been in Taiwan for a few days now, asking TSMC to boost its 3nm process node production by 50% to allocate more silicon for NVIDIA's mega-successful Blackwell GPUs, including the B200 and new B300 "Blackwell Ultra" AI GPUs. Reporters on the ground in Taiwan asked why Jensen was in Taiwan, to which he replied: "why am I back? Well, business is very strong. So, I came back to encourage my TSMC friends (to work hard)... business is going very, very strong and I'm here to encourage TSMC. They're doing a very good job for us and I'm here to thank them for all the hard work they're doing". In regards to Elon Musk's recent plans of building his "TeraFab" advanced chip manufacturing facility, Jensen said: "building advanced chip manufacturing is extremely hard. It's not just build the plant, but the engineering, the science and the artistry of doing what TSMC does for a living is extremely hard". Elon Musk said in relation to his idea of a Tesla TeraFab: "I think we may have to do a Tesla TeraFab. It's like (TSMC's) GigaFab, but way bigger". He continued: "Even when we extrapolate the best-case scenario for chip production from our suppliers, it is still not enough. So, I think we may have to do a Tesla TeraFab. It is like [TSMC's] Giga[fab] but way bigger. I cannot see any other way to get to the volume of chips that we are looking for, so I think we are probably going to have to build a gigantic chip fab. It's gotta be done".

[4]

Elon Musk says Tesla may need a "gigantic" chip factory for its AI ambitions

Tesla relies on TSMC and Samsung for chips but says even their best-case production won't meet future needs. According to CNBC, Tesla CEO Elon Musk stated the company may need a "gigantic" semiconductor fabrication plant for its artificial intelligence and robotics initiatives. Musk expressed this need at Tesla's annual shareholders meeting on Thursday, noting the challenge in securing sufficient chips. He stated, "One of the things I'm trying to figure out is -- how do we make enough chips?" Tesla currently contracts Taiwan Semiconductor Manufacturing Company (TSMC) and Samsung Electronics for chip production. Musk also indicated consideration of a partnership with U.S. chip company Intel. He added, "But even when we extrapolate the best-case scenario for chip production from our suppliers, it's still not enough." Musk anticipates a "gigantic" chip fab, which he termed a "Tesla terra fab," stating, "I can't see any other way to get to the volume of chips that we're looking for." Demand for microchips, powering various modern technologies from consumer electronics to data centers, has increased significantly due to the AI boom. Tech organizations, including Tesla, seek more supply from chipmakers like TSMC, which is the world's largest and most advanced. Musk indicated Tesla's prospective fab would initially target 100,000 wafer starts per month, with an eventual scale-up to 1 million. Wafer starts per month measure new chip production. In comparison, TSMC reported an annual wafer production capacity of 17 million in 2024, approximately 1.42 million wafer starts per month. Tesla designs custom autonomous driving chips but does not yet manufacture them. The company currently outsources production of its "AI5" chip. Musk detailed this chip will be cheaper, power-efficient, and optimized for Tesla's AI software. Musk also announced that Tesla will commence production of its Cybercab, an autonomous electric vehicle without pedals or a steering wheel, in April. Musk characterized AI and robotics as fundamental to the global economy's future. He noted, "With AI and robotics, you can actually increase the global economy by a factor of 10, or maybe 100. There's not, like, an obvious limit."

[5]

Elon Musk Dropped the Name of a Possible Chip Partner for Tesla Last Night

After a string of recent high-profile deals for Intel, could one with Tesla be next? The question became inevitable after Tesla (TSLA) CEO Elon Musk told investors at the electric vehicle maker's shareholder meeting yesterday that the company, which has increasingly shifted its focus on AI and robotics, would need a "gigantic" semiconductor fabrication plant to support its AI ambitions and that he's considering working with Intel (INTC) to make new chips. For Intel, a deal with Tesla would mark another big step in its turnaround plan, particularly if it came with commitments to its foundry manufacturing business, which has so far struggled to draw new clients. The chipmaker has also reportedly solicited business from Apple (AAPL). Shares of Intel climbed in early trading Friday following the news before paring back those gains. (Read our daily markets coverage here.) They were little changed recently, while Tesla shares were down about 4%. Intel declined to respond to Investopedia's questions about Musk's statement, while Tesla did not respond in time for publication. The move could also buy some political goodwill for Tesla after a public spat between Elon Musk and President Donald Trump earlier this year. Some analysts suggest that companies may be see deals with Intel as opportunities to make inroads with the Trump administration. Intel's stock has surged over 85% in 2025 so far, with most of that rise following a series of deals over the last few months -- among them a partnership with AI chip leader Nvidia (NVDA), after Trump brokered an agreement giving the U.S. government a 10% stake in the chipmaker in August. Several analysts have noted those deals have not come with foundry commitments yet, leading most to maintain neutral or bearish ratings. Not one of the analysts with current ratings collected by Visible Alpha recommends buying the stock.

[6]

Elon Musk plans Tesla mega AI chip fab, mulls potential Intel partnership

Elon Musk revealed Tesla's potential need to construct a massive chip fabrication plant to meet its AI chip demands, even considering collaboration with Intel. This move supports Tesla's autonomous driving and AI ambitions, as current supplier capacity is deemed insufficient for future production needs. CEO Elon Musk on Thursday said Tesla probably will have to build "a gigantic chip fab" to make artificial intelligence chips and publicly mused the EV maker could work with Intel. Tesla is designing its fifth-generation AI chip to power its autonomous ambitions, and Musk at the company's annual meeting laid out potential manufacturing plans. "You know, maybe we'll, we'll do something with Intel," Musk said to a cheering crowd of Tesla shareholders. "We haven't signed any deal, but it's probably worth having discussions with Intel." Struggling U.S. chipmaker Intel has its own chipmaking factories, but has lagged far behind Nvidia in the AI chip race. The U.S. government recently took a 10% stake in Intel, which needs to find an external customer for its newest manufacturing technology. Intel shares popped 4% in after-hours trading on Musk's remarks. Intel declined to comment. Musk scored an important victory on Thursday as shareholders approved a $1 trillion pay package over the next decade, endorsing his vision of morphing the EV maker into an AI and robotics juggernaut. Musk has teased the AI5 chip before and reiterated that Tesla was also partnering with Taiwan's TSMC and South Korea's Samsung. The AI chips power Tesla's autonomous driving systems, including the Full Self-Driving software. Tesla is currently on its fourth-generation chip. A small number of AI5 units would be produced in 2026, with high volume production only possible in 2027, Musk said in an X post on Tuesday, adding that AI6 will use the same fabs but achieve roughly twice the performance with volume production mid-2028. "Even when we extrapolate the best-case scenario for chip production from our suppliers, it's still not enough," he said on Thursday. "So I think we may have to do a Tesla terafab. It's like giga but way bigger. I can't see any other way to get to the volume of chips that we're looking for. So I think we're probably going to have to build a gigantic chip fab. It's got to be done," he said. Musk, who often talks about his vision for the company in abstract terms, did not offer details of how such a fab would be built, but he said that it would make at least 100,000 wafer starts per month. A wafer start is the measurement of the output of a semiconductor wafer plant. He did say the chip would be inexpensive, power-efficient and optimized for Tesla's own software. This chip would probably consume about a third of the power used by Nvidia's flagship Blackwell chip, at 10% of the cost to make, Musk said. "I'm super hardcore on chips right now as you may be able to tell," he said. "I have chips on the brain."

[7]

Ming-Chi Kuo Says Elon Musk's AI Chip Strategy Is No Bluff -- Tesla's Plan To Build Its Own Fabs Marks A Major Shift Away From TSMC: Here's Why - NVIDIA (NASDAQ:NVDA), Tesla (NASDAQ:TSLA)

On Sunday, TF International Securities analyst Ming-Chi Kuo said Elon Musk's remarks confirm that Tesla Inc.'s (NASDAQ:TSLA) move to build its own semiconductor production plants isn't just an ambition -- it's a calculated step toward full control of its AI future. Musk's Chip Push Aligns With Analyst's Predictions Kuo said on X, formerly Twitter, that Musk's comments at Tesla's shareholder meeting validated his earlier analysis about the automaker's semiconductor roadmap. At the meeting, Musk said, "I'm hopeful that we can within less than a year of AI5 starting production, we can actually transition in the same fab to AI6 and double all of the performance metrics." Kuo noted that while many doubted Tesla could move from the AI5 to AI6 chip in just a year, Musk's statement supports that aggressive timeline. See Also: Dan Ives Expects Elon Musk's $1 Trillion Pay Plan To Pass, Adam Jonas Warns Of Risks Ahead Of Tesla Vote Why Tesla Wants To Build Its Own Chip Plants According to Kuo, Musk's desire to build Tesla's own fabs goes beyond fears of chip shortages. While Musk warned that even in the best-case scenario, chip production from "our suppliers" is still not enough, Kuo said supply isn't the real issue -- at least not with Taiwan Semiconductor Manufacturing Co. (NYSE:TSM). He cited TSMC CEO CC Wei's past remark to Musk: "If you're willing to pay, there will be chips." Instead, Kuo believes Musk's motivation stems from three factors -- geopolitical risks, R&D flexibility and vertical integration. Musk is clearly aware of the concentration of advanced chip capacity in Taiwan, Kuo said, adding that even by 2030, only about 10% of TSMC's advanced packaging capacity will be in the U.S. Gene Munster Say Breaking From Nvidia Won't Be Easy At the shareholder meeting, Musk declared he's "super hardcore on chips right now," boasting that Tesla's AI5 chip would rival Nvidia Corporation's (NASDAQ:NVDA) new Blackwell chip while using a third of the power and costing less than 10% as much. However, Deepwater Asset Management's Gene Munster cautioned that moving away from Nvidia is easier said than done, warning that Tesla has "better places" to spend $20 billion than building chip fabs. Tesla shares have risen 13.25% year to date. Benzinga's Edge Stock Rankings show the company maintaining a solid upward trajectory across short, medium and long-term periods. Click here for an in-depth comparison of Tesla's performance against its peers and competitors. Read More: Tesla Investor Ross Gerber Says 'Super Sad' To See Federal EV Subsidies End: 'Credits Created...' Disclaimer: This content was partially produced with the help of AI tools and was reviewed and published by Benzinga editors. Photo Courtesy: Photo Agency on Shutterstock.com NVDANVIDIA Corp$190.201.13%OverviewTSLATesla Inc$432.05-3.11%TSMTaiwan Semiconductor Manufacturing Co Ltd$288.57-0.23%Market News and Data brought to you by Benzinga APIs

[8]

NVIDIA CEO Jensen Huang Pushes Back on Elon Musk's 'Bold Plans' to Build a Chip Fab, Saying What TSMC Does Is "Extremely Hard"

NVIDIA's Jensen Huang has responded to Elon's statements about building a chip fab, saying that it's almost impossible to match the work that TSMC does. For those unaware, while speaking to his shareholders, billionaire Elon Musk revealed his intentions to build a gigantic chip facility to support Tesla's ambitions in custom chips, such as the AI5. He intends to have a fab that can generate a whopping one million chips per month over time. These statements did come after Elon managed to receive a $1 trillion pay package approval, so there's no surprise that he gave a rather 'ambitious' talk, but interestingly, NVIDIA's Jensen Huang responded to the idea. While talking in Taiwan, here's what he had to say: Building advanced chip manufacturing is extremely hard. It's not just build the plant, but the engineering, the science and the artistry of doing what TSMC does for a living is extremely hard. There's no surprise in what NVIDIA's CEO has said, claiming that chip fabrication isn't an expertise that can be accomplished overnight, and even entities like Intel Foundry are struggling with it, despite being in the business for several years. The idea from Elon Musk came around the fact that the chip output from TSMC, Samsung, and potentially Intel wouldn't be enough for Tesla's custom chips, and that the automaker is exploring plans to enter the chip business itself, creating a "TeraFab". This venture alone could cost 'hundreds of billions' if not less for Tesla. NVIDIA's CEO Jensen Huang is currently in Taiwan, where he is expected to meet with TSMC's executives to discuss the supply chain situation. TSMC has become an integral part of NVIDIA's AI business, as the Taiwan chip giant powers Team Green's 'AI revolution' and is the sole semiconductor supplier. Not only this, but TSMC is doing business with every major company involved in computing, which shows that rivaling the firm isn't an easy business at all. By the looks of it, Tesla needs massive chip capacity to fuel its vehicles and humanoid robots, which opens up enormous prospects for companies like Samsung and Intel, which are looking to get adoption for their high-end chips. At the same time, Tesla's TeraFab ambition won't be an easy one at all, but Elon is known for achieving things that seem 'impossible' at first.

[9]

Nvidia CEO Jensen Huang Pushes Back On Elon Musk's Plan To Build Chip Fab, Says What TSMC Does Is 'Extremely Hard' - NVIDIA (NASDAQ:NVDA), Intel (NASDAQ:INTC)

Nvidia Corporation (NASDAQ:NVDA) CEO Jensen Huang seems to have cautioned Tesla Inc. (NASDAQ:TSLA) boss Elon Musk against underestimating the complexities of semiconductor manufacturing. Jensen Huang Comments On Musk's Chip Fab Ambition Earlier this week, Musk told Tesla shareholders that he plans to build a massive in-house chip fabrication plant to support the automaker's growing AI ambitions. The facility, Musk said, could eventually produce up to one million chips per month, designed to power Tesla's next-generation AI5 processors and the company's Dojo supercomputers. His announcement followed shareholder approval of his $1 trillion pay package. While in Taiwan this week, Huang -- whose company relies on TSMC for advanced chip production -- offered a response. On Friday, He said that building an advanced chip fab is "extremely hard," highlighting that it's not just about constructing a plant but mastering the engineering, science, and artistry that make TSMC the world's most advanced foundry. See Also: Tesla's $1 Trillion Illusion: Elon Musk's Pay Package And The Robotaxi Myth Musk's Strategy: Diversify And Control The Supply Chain During the shareholder meeting, Musk acknowledged that Tesla currently partners with TSMC and Samsung Electronics Co. (OTC:SSNLF) and hinted at potential talks with Intel Corp (NASDAQ:INTC), saying it's "probably worth having discussions." TSMC closed at $286.50 on Friday, down 0.94%, while its after-hours trading rose 0.72% to $288.57. Benzinga's Edge Stock Rankings show that TSMC maintains a solid upward trajectory across short, medium, and long-term time frames. Click here for an in-depth comparison with its competitors. Disclaimer: This content was partially produced with the help of AI tools and was reviewed and published by Benzinga editors. Image via Shutterstock INTCIntel Corp $38.282.79% Overview NVDANVIDIA Corp $190.201.13% SSNLFSamsung Electronics Co Ltd $65.2154.0% TSLATesla Inc $432.05-3.11% Market News and Data brought to you by Benzinga APIs

[10]

Elon Musk Declares "Chips on the Brain," Plans "Gigantic" Tesla AI Fab and Mulls Intel Partnership

In a move that would surprise a few in the semiconductor world, Tesla CEO Elon Musk announced plans for a "gigantic chip fab" to build Tesla's own AI chips, all while publicly mulling a new foundry partnership with Intel. Speaking at Tesla's annual shareholder meeting Thursday, Musk, fresh off securing a controversial $1 trillion pay package, laid out an aggressive new vision for Tesla's silicon. He stated that even with existing partners TSMC and Samsung, the supply of AI chips is "still not enough" to meet his ambitions for Full Self-Driving (FSD) and the Optimus humanoid robot. "I think we may have to do a Tesla terafab... it's like giga but way bigger," Musk said. "I can't see any other way to get to the volume of chips that we're looking for." This "terafab," according to Musk, would be a colossal facility with at least 100,000 wafer starts per month. But the most immediate bombshell was his open courting of Intel, a move that sent Intel's stock jumping 4% in after-hours trading. "You know, maybe we'll, we'll do something with Intel," Musk uttered to a cheering crowd. "We haven't signed any deal, but it's probably worth having discussions with Intel." For Intel Foundry Services (IFS), which has struggled to land a high-volume, next-generation anchor client, a potential Tesla deal would mean a monumental victory. If it happens, it would validate their high-stakes, multi-billion-dollar bet on becoming a world-class foundry and would go on to prove that major tech players are now seriously considering them as a primary alternative to TSMC and Samsung. Musk's entire strategy seemingly is to present a clear alternate to NVIDIA's AI dominance. While he praised NVIDIA's hardware, he made it clear that Tesla "cannot be dependent on a single supplier" for the "tens of millions" of AI chips he needs. He then made a typically bold claim, estimating Tesla's custom-designed chip would be "inexpensive, power-efficient" and would "probably consume about a third of the power used by Nvidia's flagship Blackwell chip, at 10% of the cost to make." While these figures are highly ambitious, the message is clear: Musk is done with with being at the mercy of NVIDIA's high-margin, supply-constrained GPU market and is willing to spend billions to build a vertically integrated alternative. "I'm super hardcore on chips right now as you may be able to tell," Musk added. "I have chips on the brain." Musk's announcement certainly doesn't mean he's dropping his existing partners. Instead, he appears to be building a multi-foundry "all of the above" strategy to ensure Tesla's supply chain is invulnerable. This new plan complements recent news, including: By bringing Intel into the fold as a potential partner and planning to build his own "terafab," Musk is all set to pit the world's top three foundries against each other. This creates a hyper-competitive environment that can drive down prices and guarantee Tesla gets the capacity it needs for its FSD and robotics ambitions.

[11]

TSMC, Samsung, Intel? Why Tesla's Chip Strategy Is Trying To Cover Every Foundry - Tesla (NASDAQ:TSLA)

Elon Musk has a new problem -- and it's not demand for Tesla Inc's (NASDAQ:TSLA) cars. It's the global shortage of silicon to power his next wave of AI ambitions. "How do we make enough chips?" he asked at Tesla's annual shareholder meeting, sounding less like a car CEO and more like a semiconductor executive. Track TSLA stock here. Musk revealed that Tesla is already working with both Taiwan Semiconductor Manufacturing Co Ltd (NYSE:TSM) and Samsung Electronics Co., Ltd (OTCPK:SSNLF) to manufacture its upcoming AI5 chip -- the brain behind Tesla's self-driving systems and AI infrastructure. But even that, he warned, won't be enough. "Even when we extrapolate the best-case scenario for chip production from our suppliers, it is still not enough," he said. That's why Tesla is now exploring potential talks with Intel -- and, in true Musk fashion, considering an even bolder move: building its own "TeraFab." Musk's Foundry Shuffle For an automaker, juggling TSMC, Samsung, and possibly Intel Corp (NASDAQ:INTC) sounds like overkill. For Musk, it's insurance. As AI models grow and Tesla's own Dojo supercomputer scales, the demand for advanced chips is exploding. Relying on any single foundry could choke Tesla's AI roadmap. Diversifying production across multiple fabs, and eventually building one in-house, gives Musk control over his most crucial input. "I have a lot of respect for our partners, TSMC and Samsung," he said. "Maybe we'll do something with Intel -- we haven't signed any deal, but it's probably worth having discussions." Translation: Musk is playing the field to guarantee Tesla's chip pipeline stays open, even as global foundry capacity remains tight. The Bigger Bet This strategy isn't just about supply -- it's about scale. Musk wants Tesla's AI chips to evolve faster than the industry's cadence, moving from AI5 to AI6 "within less than a year" and "doubling all performance metrics." To pull that off, he may need to own the process from design to wafer. If Tesla follows through on the TeraFab vision, it would mark a stunning pivot -- from automaker to vertically integrated AI hardware giant. For now, Musk's question still hangs in the air: "How do we make enough chips?" But, judging by his tone, he's not waiting for TSMC, Samsung, or Intel to answer it for him. Read Next: Musk's $1 Trillion Moment: The Bet That Could Reprice Tesla Stock Or Break It Photo: Shutterstock TSLATesla Inc$428.44-3.92%OverviewINTCIntel Corp$37.350.30%SSNLFSamsung Electronics Co Ltd$42.480.34%TSMTaiwan Semiconductor Manufacturing Co Ltd$278.02-3.88%Market News and Data brought to you by Benzinga APIs

[12]

Elon Musk Hints at a Massive Intel-Tesla Foundry Deal, Saying It's Worth "Having Discussions" With Team Blue

It appears that Tesla is seeking to add more chip suppliers, and following its agreements with TSMC and Samsung, the automaker is now interested in Intel's foundry services. When it comes to external customers, Intel Foundry hasn't managed to secure much volume, and while the firm's 18A process has panned out to be a competitive platform, Team Blue still hasn't managed to get the 'market spotlight'. However, according to Elon Musk's discussions surrounding the chip industry, the billionaire teased a potential collaboration with Intel Foundry, claiming that Tesla needs 'gigantic' chip production volume across all its partners. With this, the American automaker will become the first to source semiconductors from Samsung, TSMC, and Intel. Maybe we'll do something with Intel. We haven't signed any deal, but it's probably worth having discussions with Intel. Even when we extrapolate the best case scenario for chip production form our suppliers. it is still not enough. - Elon Musk Given that Tesla does manage to secure a deal with Intel, it would likely revolve around the 18A node for now, considering that the process is IFS's most competitive offering, and more importantly, Tesla is looking for '2nm suppliers' for its next-gen AI6 AI chips. For those unaware, Intel was previously rumored to provide advanced packaging services for Tesla's Dojo supercomputer; however, with the venture's shutdown, rumors of a deal were stalled. Now, we are exploring a collaboration on the semiconductor front, which would be a significantly more attractive deal for Intel. Based on the 'Big Three' chip firms out there, Intel has the most 'advanced chip fab' in the US as of now, and the company's Arizona Fab 52 facility is currently mass-producing the 18A node, which is a direct counterpart to TSMC's N2 and Samsung's SF2. Given that Tesla values 'manufacturing in America', a partnership with Intel becomes more sensible in this case, as it provides the automaker with access to a cutting-edge facility right in the US. However, for now, we are unaware of how a potential Intel-Tesla deal could evolve, since Musk hasn't revealed any specifics.

[13]

Intel shares rise as Elon Musk touts potential Tesla chipmaking deal By Investing.com

Investing.com-- Intel shares rose in aftermarket trading on Thursday after Tesla CEO Elon Musk said the electric vehicle maker could enter a deal with the chipmaker for artificial intelligence and robotics processors. Intel Corporation (NASDAQ:INTC) rose 2.2% to $38.06 by 18:29 ET (23:29 GMT). Speaking at a Tesla Inc (NASDAQ:TSLA) shareholder meeting, Musk said Tesla may work with Intel to source chips for its autonomous driving and robotics ambitions. He also raised the possibility of Tesla building its own chip factory, citing an outsized need for chips from Tesla's robotaxi and robotics ambitions. Tesla currently has deals with chipmakers TSMC and Samsung to build its AI series of chips, which are used in its EVs. Musk had said during Tesla's third-quarter that TSMC and Samsung will develop the upcoming AI5 chip at their U.S. facilities, and that the company had no plans to replace Nvidia as its main provider of data center hardware. A deal with Tesla could provide Intel with a much needed shot in the arm, especially as the chipmaker largely lagged its peers in capitalizing on AI-driven demand over the past three years. Musk's comments came after Tesla shareholders overwhelmingly approved a $1 trillion pay package for the CEO.

[14]

Gene Munster Says Elon Musk Has Talked About Moving Away From Nvidia Before, But It's 'Proven Extremely Hard To Do' As Tesla Doubles Down On AI5 Chip - Tesla (NASDAQ:TSLA)

Tesla Inc. (NASDAQ:TSLA) CEO Elon Musk is ramping up efforts to build an in-house artificial intelligence chip, the AI5, but Gene Munster warns that moving away from Nvidia Corp. (NASDAQ:NVDA) has proven far more difficult than Musk's ambitious projections suggest. Elon Musk Says He 'Dreams About Chips' At Tesla's annual shareholder meeting on Thursday, Musk said he is "super hardcore on chips right now," underscoring that developing a custom AI chip is key to advancing Tesla's robotics and self-driving programs. He stated that Tesla's upcoming AI5 chip will deliver roughly comparable performance to Nvidia's new Blackwell chip while using only one-third of the power and costing less than 10% as much. Musk said Tesla's advantage comes from building chips specialized for its software stack rather than catering to a wide range of applications, as Nvidia must do. He also highlighted Tesla's use of integer-based inference -- which he described as more power and silicon-efficient than floating-point operations -- though it requires specialized training. The AI5 chip will be manufactured by both Taiwan Semiconductor Manufacturing Co. (NYSE:TSM) and Samsung Electronics Co. (OTC:SSNLF), with production spread across facilities in Taiwan, South Korea, Arizona and Texas. Musk added that Tesla already has plans for the AI6 chip, expected to double performance within a year of AI5's rollout. See Also: Tesla's $1 Trillion Illusion: Elon Musk's Pay Package And The Robotaxi Myth Gene Munster Cautions Against Underestimating Nvidia Deepwater Asset Management managing partner Munster reacted to Musk's comments, saying Tesla's goal to move away from Nvidia is easier said than done. "Musk says they're building their own chip for inference, reducing the need for Nvidia GPUs," Munster noted. "He's talked about moving away from $NVDA before and it's proven extremely hard to do." He added that while Tesla could work with Intel Corp (NASDAQ:INTC) or build a large chip fabrication plant, "they have better places" to spend $20 billion. Cathie Wood Backs Tesla's AI Ambitions Earlier this week, ARK Invest CEO Cathie Wood also weighed in, calling Tesla's AI5 chip a potential game-changer after tech advisor Brian Roemmele said it could be "40 times faster" and "10 times cheaper per inference" than Nvidia's hardware. "If Brian Roemmele thinks Tesla's A15 chip will be a big deal, then it will be a big deal," Wood wrote on X at the time. Musk later confirmed that sample chips could arrive in 2026, with full-scale production likely in 2027. Last month, Tesla reported third-quarter revenue of $28.1 billion, a 12% year-over-year increase that beat Wall Street's consensus estimate of $26.24 billion. The stock closed at $445.91 on Thursday, down 3.54%, before rising 1.57% to $452.90 in after-hours trading. According to Benzinga's Edge Stock Rankings, Tesla continues to show a strong upward trend across short, medium and long-term periods. Click here for a detailed look at how it compares with its peers and competitors. Disclaimer: This content was partially produced with the help of AI tools and was reviewed and published by Benzinga editors. Photo courtesy: Shutterstock TSLATesla Inc $452.90-1.98% Overview INTCIntel Corp $38.21-0.44% NVDANVIDIA Corp $189.68-2.83% SSNLFSamsung Electronics Co Ltd Not Available-% TSMTaiwan Semiconductor Manufacturing Co Ltd $290.70-1.00% Market News and Data brought to you by Benzinga APIs

Share

Share

Copy Link

Tesla CEO Elon Musk announced the company may need to build a "gigantic" semiconductor fabrication plant to meet its AI and robotics chip demands. He's also considering partnerships with Intel, as current suppliers TSMC and Samsung cannot meet projected needs.

Tesla's Chip Manufacturing Ambitions

Tesla CEO Elon Musk announced at the company's annual shareholders meeting that Tesla will likely need to construct a "gigantic" semiconductor fabrication plant to support its expanding artificial intelligence and robotics initiatives

1

. The proposed facility, which Musk dubbed a "Tesla terra fab," represents a significant strategic shift for the electric vehicle manufacturer as it pivots toward AI-driven technologies.Source: Benzinga

"One of the things I'm trying to figure out is -- how do we make enough chips?" Musk stated during the meeting, highlighting the supply constraints facing Tesla's ambitious technology roadmap

1

. The proposed fabrication plant would have an initial capacity of 100,000 wafer starts per month, eventually scaling to 1 million wafer starts monthly2

.Current Supply Chain Challenges

Tesla currently relies on contract manufacturers Taiwan Semiconductor Manufacturing Company (TSMC) and Samsung Electronics to produce its custom chip designs

1

. Despite these partnerships, Musk emphasized that "even when we extrapolate the best-case scenario for chip production from our suppliers, it's still not enough"4

.The semiconductor shortage has become particularly acute amid the AI boom, with tech giants competing for limited manufacturing capacity from leading chipmakers like TSMC, the world's largest and most advanced semiconductor manufacturer

1

. For context, TSMC's annual wafer production capacity reached 17 million in 2024, equivalent to approximately 1.42 million wafer starts per month2

.Potential Intel Partnership

Musk also revealed that Tesla is considering a partnership with Intel to help meet its chip manufacturing needs. "Maybe we'll do something with Intel," Musk said, though he clarified that "we haven't signed any deal, but it's probably worth having discussions with Intel"

2

.

Source: Wccftech

This potential collaboration could provide a significant boost to Intel's foundry business, which has struggled to attract major clients despite recent investments in advanced manufacturing capabilities

5

. Intel's stock price jumped 2.2% following Musk's comments, while Tesla shares rose 4% in after-hours trading2

.Related Stories

Industry Skepticism and Challenges

Not everyone in the semiconductor industry views Tesla's manufacturing ambitions favorably. NVIDIA CEO Jensen Huang, currently visiting Taiwan to strengthen relationships with TSMC, expressed skepticism about Tesla's plans. "Building advanced chip manufacturing is extremely hard," Huang told reporters, emphasizing that "the engineering, the science and the artistry of doing what TSMC does for a living is extremely hard"

3

.

Source: Benzinga

Huang's comments underscore the significant technical and financial challenges associated with building advanced semiconductor manufacturing facilities, which require billions of dollars in investment and years of development.

Tesla's AI-Driven Future

Musk's chip manufacturing plans align with Tesla's broader strategic shift toward AI and robotics. The company is finalizing designs for its A15 chip, which reportedly offers a 40x improvement over the current A14 processor, with small-scale production planned for 2026 and high-volume manufacturing in 2027

2

.The A16 chip, scheduled for volume production in 2028, is expected to double the performance of its predecessor while consuming approximately one-third of the power used by NVIDIA's Blackwell chip at 10% lower manufacturing costs

2

.Musk characterized AI and robotics as transformational for the global economy, stating, "With AI and robotics, you can actually increase the global economy by a factor of 10, or maybe 100. There's not, like, an obvious limit"

1

.References

Summarized by

Navi

[3]

Related Stories

NVIDIA CEO Jensen Huang Secures 50% Production Boost from TSMC Amid Soaring AI Chip Demand

09 Nov 2025•Business and Economy

Nvidia CEO warns TSMC must double capacity as AI demand threatens to overwhelm chip supply

01 Feb 2026•Business and Economy

Elon Musk Announces Ambitious Plan to Outproduce All AI Chip Makers Combined with Tesla's Custom Silicon

25 Nov 2025•Technology

Recent Highlights

1

Google Gemini 3.1 Pro doubles reasoning score, beats rivals in key AI benchmarks

Technology

2

Meta strikes up to $100 billion AI chips deal with AMD, could acquire 10% stake in chipmaker

Technology

3

Pentagon threatens Anthropic with supply chain risk label over AI safeguards for military use

Policy and Regulation