AI-Driven 'Polybot' Revolutionizes Electronic Polymer Discovery at Argonne National Laboratory

2 Sources

2 Sources

[1]

Self-driving lab transforms electronic polymers discovery

Plastic that conducts electricity might sound impossible. But there is a special class of materials known as "electronic polymers" that combines the flexibility of plastic with the functionality of metal. This type of material opens the door for breakthroughs in wearable devices, printable electronics and advanced energy storage systems. Yet, making thin films from electronic polymers has always been a difficult task. It takes a lot of fine-tuning to achieve the right balance of physical and electronic properties. Researchers at the U.S. Department of Energy's (DOE) Argonne National Laboratory have created an innovative solution to this challenge with artificial intelligence (AI). They used an AI-driven, automated materials laboratory, a tool called Polybot, to explore processing methods and produce high-quality films. Polybot is located at the Center for Nanoscale Materials, a DOE Office of Science user facility at Argonne. Polybot is the latest method in autonomous discovery, a general approach that combines robotics with the power of AI to accelerate discovery and innovation. The research is published in Nature Communications. "Polybot operates on its own, with a robot running the experiments based on AI-driven decisions," said Jie Xu, a scientist at Argonne. "We are creating a method that highlights how AI and automation can transform chemical engineering and materials science." The researchers used Polybot to solve key challenges in electronic polymer processing. For example, the final properties of these materials are influenced by a complex production history. There are nearly a million possible combinations in the fabrication process that can affect the final properties of the films -- far too many possibilities for humans to test. "We faced limited resources and had little knowledge about the vast processing options," said Henry Chan, a computational materials scientist at Argonne. "Using AI-guided exploration and statistical methods, Polybot efficiently gathered reliable data, helping us find thin film processing conditions that met several material goals." Polybot helped the researchers simultaneously optimize two key properties: conductivity and coating defects. Improving conductivity and reducing defects makes devices more reliable and boosts electrical performance. This fully automated platform streamlines the formulation, coating and post-processing steps, allowing for quick experimentation and data collection. As a result, the team was able to create thin films with average conductivity comparable to the highest standards currently achievable. They also developed "recipes" for large-scale production of these films. Further, one of the key achievements of this project, according to Argonne research scientist Aikaterini Vriza, is the use of advanced computer programs that can process and analyze images. "These programs not only helped us perform experiments and create films, but they also allowed us to capture images and evaluate the quality of the films," Vriza said. "This information was crucial to our efforts to produce high-quality, highly conductive films." In addition to making films, the researchers collected valuable data, which they plan to share with the scientific community through a database. This adds significant value to their work. "Data is critical," Vriza said. "We support open-source research, and by sharing this data, we hope to motivate the community to contribute to, test and improve our methodology." The impact of this work goes beyond just making electronic polymers in the laboratory. It also establishes important guidelines for large-scale production. The recipes and instructions from this research provide practical advice for scientists and manufacturers who want to explore the potential of electronic polymers in various applications. "This project is just the beginning," Xu said. "We've shown that our approach works. Next, we want to dive deeper into using AI and automated processes to tackle more real-world challenges and help discover new materials." This research made use of the Materials Engineering Research Facility at Argonne for electronic printing support and the National Synchrotron Light Source II at DOE's Brookhaven National Laboratory for wide-angle X-ray scattering characterization.

[2]

Self-driving lab transforms materials discovery | Newswise

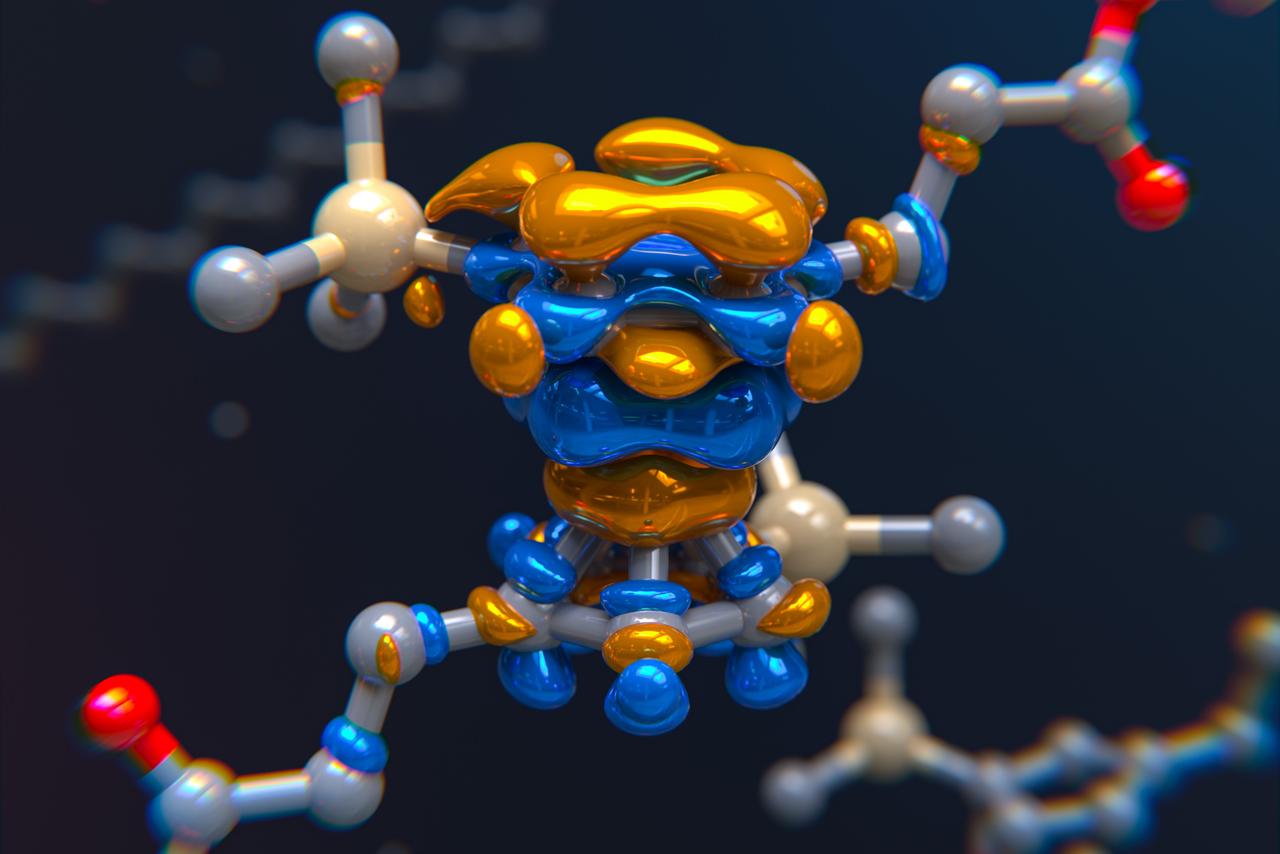

Artistic rendering depicting Polybot, the AI-driven automated material laboratory. Argonne researchers use Polybot, an AI-driven automated material laboratory, to produce high-conductivity, low-defect electronic polymer thin films. Plastic that conducts electricity might sound impossible. But there is a special class of materials known as "electronic polymers" that combines the flexibility of plastic with the functionality of metal. This type of material opens the door for breakthroughs in wearable devices, printable electronics and advanced energy storage systems. Yet, making thin films from electronic polymers has always been a difficult task. It takes a lot of fine-tuning to achieve the right balance of physical and electronic properties. Researchers at the U.S. Department of Energy's (DOE) Argonne National Laboratory have created an innovative solution to this challenge with artificial intelligence (AI). "We are creating a method that highlights how AI and automation can transform chemical engineering and materials science." -- Jie Xu, Argonne scientist They used an AI-driven, automated materials laboratory, a tool called Polybot, to explore processing methods and produce high-quality films. Polybot is located at the Center for Nanoscale Materials, a DOE Office of Science user facility at Argonne. Polybot is the latest method in autonomous discovery, a general approach that combines robotics with the power of AI to accelerate discovery and innovation. "Polybot operates on its own, with a robot running the experiments based on AI-driven decisions," said Jie Xu, a scientist at Argonne. "We are creating a method that highlights how AI and automation can transform chemical engineering and materials science." The researchers used Polybot to solve key challenges in electronic polymer processing. For example, the final properties of these materials are influenced by a complex production history. There are nearly a million possible combinations in the fabrication process that can affect the final properties of the films -- far too many possibilities for humans to test. "We faced limited resources and had little knowledge about the vast processing options," said Henry Chan, a computational materials scientist at Argonne. "Using AI-guided exploration and statistical methods, Polybot efficiently gathered reliable data, helping us find thin film processing conditions that met several material goals." Polybot helped the researchers simultaneously optimize two key properties: conductivity and coating defects. Improving conductivity and reducing defects makes devices more reliable and boosts electrical performance. This fully automated platform streamlines the formulation, coating and post-processing steps, allowing for quick experimentation and data collection. As a result, the team was able to create thin films with average conductivity comparable to the highest standards currently achievable. They also developed "recipes" for large-scale production of these films. Further, one of the key achievements of this project, according to Argonne research scientist Aikaterini Vriza, is the use of advanced computer programs that can process and analyze images. "These programs not only helped us perform experiments and create films, but they also allowed us to capture images and evaluate the quality of the films," Vriza said. "This information was crucial to our efforts to produce high-quality, highly conductive films." In addition to making films, the researchers collected valuable data, which they plan to share with the scientific community through a database. This adds significant value to their work. "Data is critical," Vriza said. "We support open-source research, and by sharing this data, we hope to motivate the community to contribute to, test and improve our methodology." The impact of this work goes beyond just making electronic polymers in the laboratory. It also establishes important guidelines for large-scale production. The recipes and instructions from this research provide practical advice for scientists and manufacturers who want to explore the potential of electronic polymers in various applications. "This project is just the beginning," Xu said. "We've shown that our approach works. Next, we want to dive deeper into using AI and automated processes to tackle more real-world challenges and help discover new materials." This research made use of the Materials Engineering Research Facility at Argonne for electronic printing support and the National Synchrotron Light Source II at DOE's Brookhaven National Laboratory for wide-angle X-ray scattering characterization. Other contributors to this work include Chengshi Wang, Yeon-Ju Kim, Rohit Batra, Arun Baskaran, Pierre Darancet, Logan Ward, Yuzi Liu, Maria K.Y. Chan, H. Christopher Fry and Christina S. Miller from Argonne; Naisong Shan and Nan Li from The University of Chicago; and Subramanian K.R.S. Sankaranarayanan from both Argonne and the University of Illinois, Chicago. The results of this research were published in Nature Communications. The study was funded by the DOE Office of Basic Energy Sciences, the Laboratory Directed Research and Development program at Argonne and the University of Chicago.

Share

Share

Copy Link

Researchers at Argonne National Laboratory have developed an AI-powered automated lab called Polybot, which is transforming the discovery and optimization of electronic polymers for advanced technologies.

AI-Powered Polybot Transforms Electronic Polymer Research

Researchers at the U.S. Department of Energy's (DOE) Argonne National Laboratory have made a significant breakthrough in materials science by developing an AI-driven automated laboratory called Polybot. This innovative tool is revolutionizing the discovery and optimization of electronic polymers, a unique class of materials that combine the flexibility of plastic with the conductivity of metal

1

.The Challenge of Electronic Polymer Production

Electronic polymers have immense potential for applications in wearable devices, printable electronics, and advanced energy storage systems. However, producing thin films from these materials has been a persistent challenge due to the complexity of balancing their physical and electronic properties. The fabrication process involves nearly a million possible combinations that can affect the final properties of the films, making it impractical for human researchers to explore all options

2

.Polybot: The AI-Driven Solution

Polybot, located at the Center for Nanoscale Materials at Argonne, represents the latest advancement in autonomous discovery. It combines robotics with artificial intelligence to accelerate innovation in chemical engineering and materials science. The system operates independently, with a robot conducting experiments based on AI-driven decisions

1

.Key Achievements of Polybot

-

Optimized Properties: Polybot simultaneously optimized two crucial properties of electronic polymer films: conductivity and coating defects. This improvement enhances device reliability and electrical performance

2

. -

Efficient Data Gathering: Using AI-guided exploration and statistical methods, Polybot efficiently collected reliable data to identify optimal thin film processing conditions

1

. -

High-Quality Film Production: The research team created thin films with average conductivity comparable to the highest current standards and developed "recipes" for large-scale production

2

. -

Advanced Image Analysis: Polybot utilized advanced computer programs for image processing and analysis, crucial for evaluating film quality

1

.

Related Stories

Impact and Future Directions

The implications of this research extend beyond laboratory settings. The team plans to share their collected data with the scientific community through an open-source database, promoting collaborative improvement of their methodology

2

.Jie Xu, a scientist at Argonne, emphasized that this project is just the beginning. The team aims to apply their AI and automation approach to tackle more real-world challenges and discover new materials

1

.Collaborative Effort and Funding

This groundbreaking research involved contributions from multiple institutions, including the University of Chicago and the University of Illinois, Chicago. The study, published in Nature Communications, was funded by the DOE Office of Basic Energy Sciences, Argonne's Laboratory Directed Research and Development program, and the University of Chicago

2

.As this AI-driven approach continues to evolve, it promises to accelerate innovation in materials science, potentially leading to breakthroughs in various technological fields and industrial applications.

References

Summarized by

Navi

Related Stories

AI-Powered Discovery of Mechanophores Paves Way for Stronger, More Durable Plastics

05 Aug 2025•Science and Research

AI Supercomputer Revolutionizes Battery Material Discovery

15 Aug 2025•Science and Research

MIT's SCIGEN: Steering AI to Create Breakthrough Quantum Materials

22 Sept 2025•Science and Research

Recent Highlights

1

ByteDance Faces Hollywood Backlash After Seedance 2.0 Creates Unauthorized Celebrity Deepfakes

Technology

2

Microsoft AI chief predicts artificial intelligence will automate most white-collar jobs in 18 months

Business and Economy

3

Google reports state-sponsored hackers exploit Gemini AI across all stages of cyberattacks

Technology